Preparation method of cathode material of lithium-rich ternary compound lithium ion battery

A lithium-ion battery and ternary composite technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as complex preparation processes, and achieve the effects of simple process, uniform precipitation, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

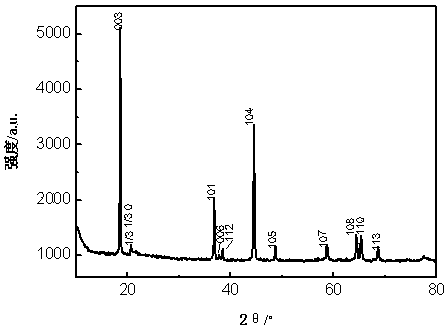

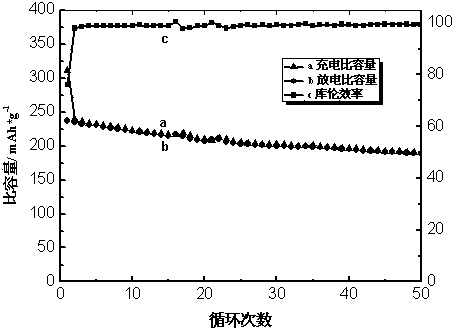

[0045] A preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material, the lithium-rich ternary composite lithium-ion battery positive electrode material contains Li, Ni, Co, Mn and O elements, and its molecular formula is Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 .

[0046] The above-mentioned preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material specifically includes the following steps:

[0047] (1) Mix 6.3870g (1% excess) of organic precipitant and 55ml of organic solvent according to the ratio of organic precipitant: organic solvent: 1mol:1L, and then stir at a controlled speed of 500r / min and a temperature of 80°C Dissolved to obtain solution 1;

[0048] Described organic precipitation agent is 8-hydroxyquinoline;

[0049] Described organic solvent is ethanol;

[0050] (2) Mix soluble 1.6190g cobalt salt, 1.6176g nickel salt, 6.61742g manganese salt and 6.4273g lithium salt with 50...

Embodiment 2

[0073] A preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material, the lithium-rich ternary composite lithium-ion battery positive electrode material contains Li, Ni, Co, Mn and O elements, and its molecular formula is Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 .

[0074] The above-mentioned preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material adopts an organic co-precipitation method, which specifically includes the following steps:

[0075] (1) Mix the organic precipitant and the organic solvent according to the ratio of organic precipitant:organic solvent: 0.5mol:1L, and then stir and dissolve under the conditions of controlling the rotational speed at 400r / min and the temperature at 40°C to obtain solution 1;

[0076] Described organic precipitation agent is 8-hydroxyquinoline;

[0077] Described organic solvent is ethanol;

[0078] (2) Combine soluble cobalt salt, nickel salt, ma...

Embodiment 3

[0088] A preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material, the lithium-rich ternary composite lithium-ion battery positive electrode material contains Li, Ni, Co, Mn and O elements, and its molecular formula is Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 .

[0089] The above-mentioned preparation method of a lithium-rich ternary composite lithium-ion battery positive electrode material adopts an organic co-precipitation method, which specifically includes the following steps:

[0090] (1) Mix the organic precipitant and the organic solvent according to the ratio of organic precipitant:organic solvent: 2.5mol:1L, then stir and dissolve under the conditions of controlling the rotation speed at 500r / min and the temperature at 60°C to obtain solution 1;

[0091] Described organic precipitation agent is 8-hydroxyquinoline;

[0092] Described organic solvent is ethanol;

[0093] (2) Combine soluble cobalt salt, nickel salt, manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com