Preparation method of piperylene modified DCPD petroleum resin

A technology of petroleum resin and pentadiene, which is applied in the field of preparation of piperylene-modified DCPD petroleum resin, can solve the problems of high raw material cost, deep hue of petroleum resin products, and decline of economic benefits of petroleum resin, and achieve high economic benefits , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

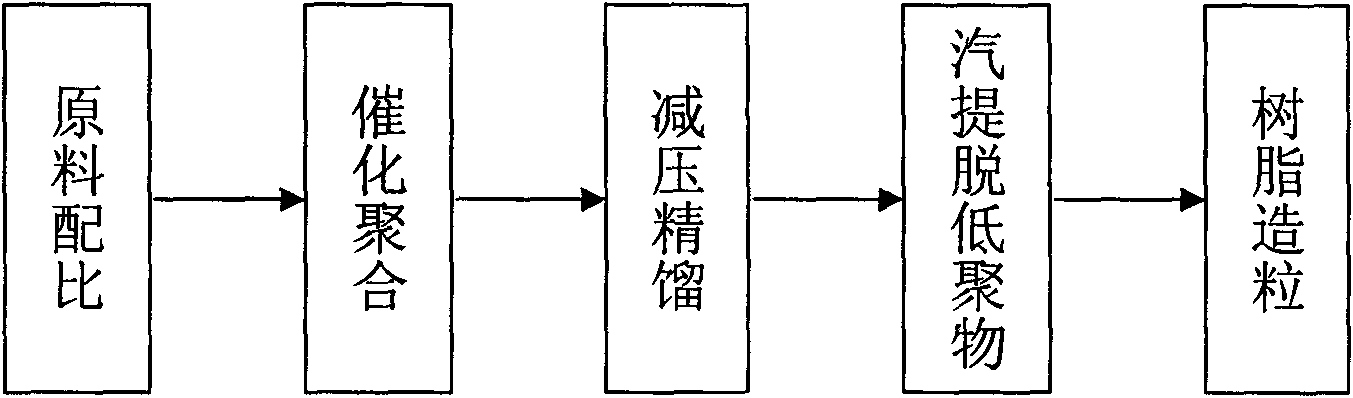

Method used

Image

Examples

Embodiment 1

[0042] The raw material containing 60% piperylene and the raw material containing 65% DCPD are mixed at a mass ratio of 1:1 as raw material. First, put the above-mentioned proportioned raw materials into a reaction kettle with a stirrer in advance, and then put in the catalyst anhydrous aluminum trichloride accounting for 1% of the raw material mass, and make the materials react at 60° C. for 5 hours to obtain a polymerization liquid. The polymerization liquid is decompressed to remove the solvent in a rectification tower with an operating pressure of -0.06MPa. The temperature of the tower bottom is 260 ° C, the temperature of the top of the tower is 150 ° C, and the reflux ratio is 5. The bottom of the tower contains petroleum resin and part of the solvent. Polymer resin solution. After the resin liquid is extracted oligomers by a stripping tower, the product petroleum resin is obtained.

Embodiment 2

[0044] The raw material containing 60% piperylene and the raw material containing 65% DCPD are mixed at a mass ratio of 1:1.5 as the raw material. First, put the above-mentioned proportioned raw materials into a reaction kettle with a stirrer in advance, and then put in the catalyst anhydrous aluminum trichloride accounting for 1.5% of the raw material mass, and make the materials react at 60° C. for 5 hours to obtain a polymerization liquid. The polymerization liquid is decompressed to remove the solvent in a rectification tower with an operating pressure of -0.07MPa. The temperature of the tower bottom is 260 ° C, the temperature of the top of the tower is 150 ° C, and the reflux ratio is 5. The bottom of the tower contains petroleum resin and part of the solvent. Polymer resin solution. After the resin liquid is extracted oligomers by a stripping tower, the product petroleum resin is obtained.

Embodiment 3

[0046] The raw material containing 60% piperylene and the raw material containing 65% DCPD are mixed at a mass ratio of 1:2 as raw material. First, put the above-mentioned proportioned raw materials into a reaction kettle with a stirrer in advance, and then put in the catalyst anhydrous aluminum trichloride accounting for 2% of the raw material mass, and make the materials react at 50° C. for 4 hours to obtain a polymerization liquid. The polymerization liquid is decompressed to remove the solvent in a rectification tower with an operating pressure of -0.08MPa. The temperature of the tower bottom is 260 ° C, the temperature of the top of the tower is 150 ° C, and the reflux ratio is 5. The bottom of the tower contains petroleum resin and part of the solvent. Polymer resin solution. After the resin liquid is extracted oligomers by a stripping tower, the product petroleum resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com