Preparation method of Fe/Mo-Al2O3 catalyst and method of synthesizing leaf alcohol by virtue of piperylene

A technology of mo-al2o3 and piperylene, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of harsh reaction conditions, complex processes, production High cost and other issues, to achieve the effect of mild process conditions, high purity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1. Preparation method of catalyst for synthesizing leaf alcohol

[0032] (1) First, 40~160 mesh γ-Al 2 O 3 The carrier is calcined at 200~800℃ for 12~48h to remove γ-Al 2 O 3 Physically adsorbed impurities in

[0033] (2) The treated γ-Al 2 O 3 Immerse in a ferric nitrate solution with a mass concentration of 0.1-10% for 12 to 48 hours, filter, wash the filter cake with distilled water for 2 to 50 minutes, and finally place it in a muffle furnace at 300 to 800°C for 3 to 12 hours to obtain a sample of Fe- Al 2 O 3 ;

[0034] (3) The obtained Fe-Al 2 O 3 Immerse in ammonium molybdate solution with a mass concentration of 0.3-10% for 12~48h, filter, wash the filter cake with distilled water for 2~50min, dry at 30~200℃ for 4~48h, and finally put it in a muffle furnace at 300~800℃ Fe / Mo-Al can be obtained by calcination for 2-12h 2 O 3 catalyst.

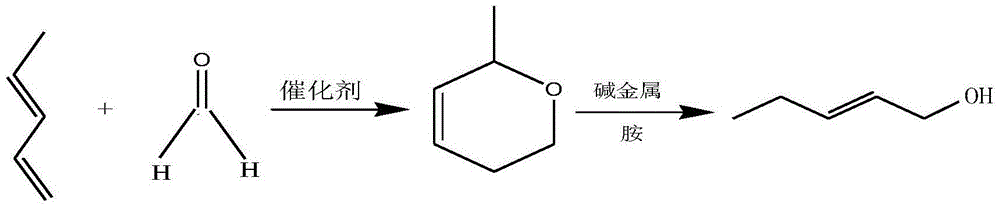

[0035] 2. Method for synthesizing leaf alcohol with the catalyst of the present invention

[0036] 1. Synthesis of intermediates

[0037]...

Embodiment 1

[0047] 1. The catalyst preparation is carried out in the following order:

[0048] (1) First, 40~60 mesh γ-Al 2 O 3 The carrier is calcined at 200℃ for 12h to remove γ-Al 2 O 3 Physically adsorbed impurities in

[0049] (2) The treated γ-Al 2 O 3 Immerse in 0.1% by mass ferric nitrate solution for 12h, filter, wash the filter cake with distilled water for 2min, and finally put it in a muffle furnace at 300℃ for 3h to obtain the sample Fe-Al 2 O 3 ;

[0050] (3) The obtained Fe-Al 2 O 3 Soaked in 0.3% ammonium molybdate solution for 12h, filtered, washed the filter cake with distilled water for 2min, dried at 30℃ for 4h, and finally placed in a muffle furnace and roasted at 300℃ for 2h to obtain Fe / Mo-Al 2 O 3 catalyst.

[0051] 2. Method of synthesizing leaf alcohol with catalyst

[0052] 1. Synthesis of intermediates

[0053] (1) Combine piperylene and catalyst Fe / Mo-Al 2 O 3 (Fe / Mo-Al 2 O 3 The mass ratio to piperylene is 0.05:1) and the solvent formaldehyde (the mass ratio of piperyle...

Embodiment 2

[0062] 1. The catalyst preparation is carried out in the following order:

[0063] (1) Firstly, 60~10 mesh γ-Al 2 O 3 The carrier is calcined at 500℃ for 36h to remove γ-Al 2 O 3 Physically adsorbed impurities in

[0064] (2) The treated γ-Al 2 O 3 Immerse in a 5% ferric nitrate solution for 36h, filter, wash the filter cake with distilled water for 25min, and finally place it in a muffle furnace at 500℃ for 9h to obtain a sample of Fe-Al 2 O 3 ;

[0065] (3) The obtained Fe-Al 2 O 3 Immerse in a 5% mass concentration of ammonium molybdate solution for 36h, filter, wash the filter cake with distilled water for 25min, dry at 100℃ for 36h, and finally put it in a muffle furnace and roast at 500℃ for 9h to obtain Fe / Mo-Al 2 O 3 catalyst.

[0066] 2. Method of synthesizing leaf alcohol with catalyst

[0067] 1. Synthesis of intermediates

[0068] (1) Combine piperylene and catalyst Fe / Mo-Al 2 O 3 (Fe / Mo-Al 2 O 3 The mass ratio to piperylene is 0.1:1) and the solvent formaldehyde (the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com