Method for preparing poly-1,3-pentadiene

A technology of pentadiene and CF3SO3, applied in the field of catalyst and its preparation, can solve the problems of corrosion of polymerization equipment and harsh preparation conditions, and achieve the effects of eliminating corrosion, reducing preparation cost and simplifying process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

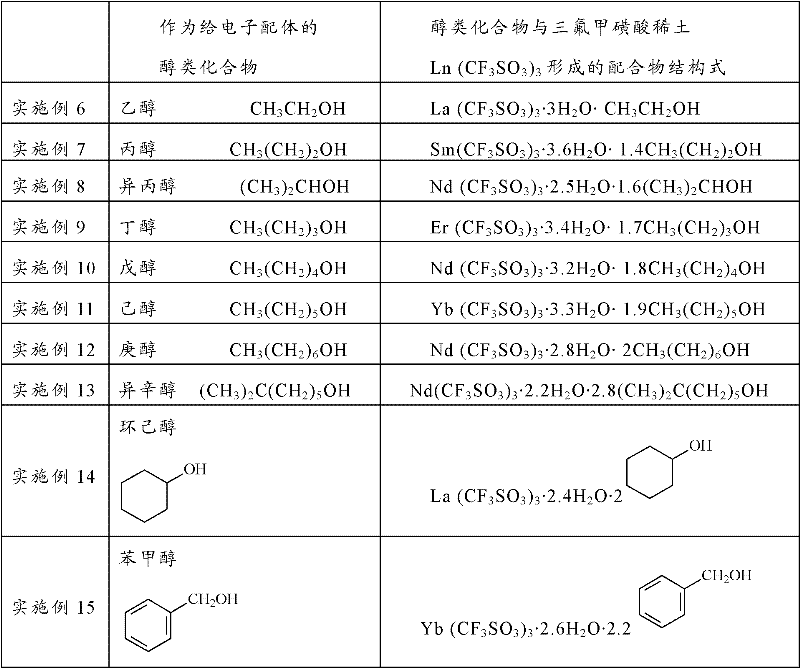

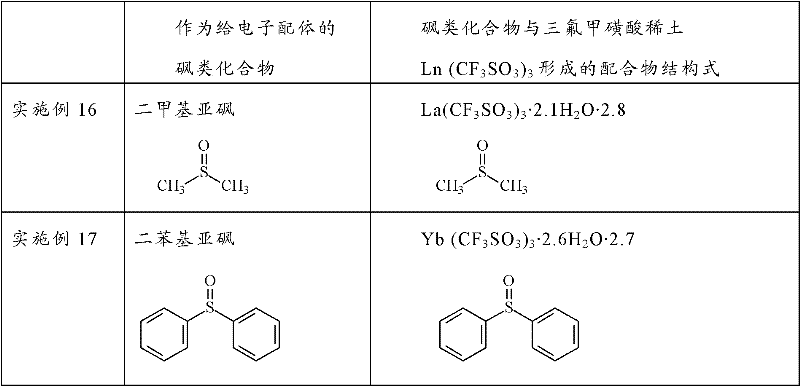

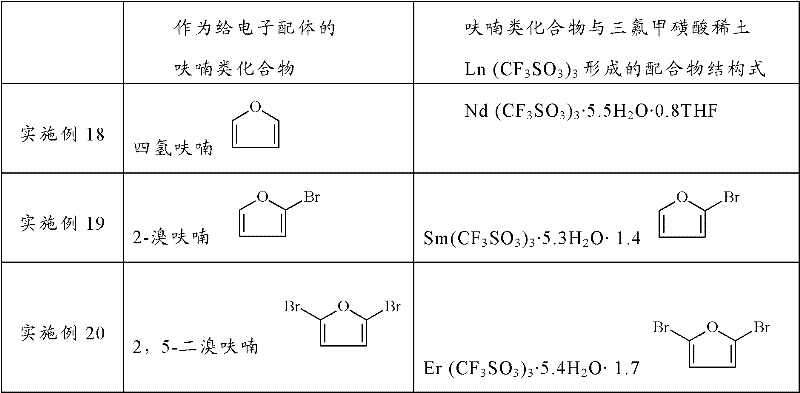

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of a rare earth complex, a) mixing trifluoromethanesulfonic acid with a rare earth oxide, and reacting to obtain a rare earth trifluoromethanesulfonic acid compound;

[0032] b) The rare earth trifluoromethanesulfonic acid compound and the electron-donating ligand are mixed in a solvent, heated to boiling and then refluxed, and then the solvent is drained to obtain the rare earth trifluoromethanesulfonic acid complex Ln(CF 3 SO 3 ) 3 ·xH 2 O·yL; wherein, Ln is a trivalent cation of a rare earth element, L is an electron-donating ligand, 0<x≤6, 1≤y≤4.

[0033] And a kind of preparation method of catalyst for 1,3-pentadiene polymerization, comprising

[0034] The molar ratio is (20-60): 1, the alkylaluminum and the trifluoromethanesulfonate rare earth complex are mixed, and aged in hexane to obtain a catalyst for the polymerization of piperylene.

[0035] There is also a preparation method of poly-1,3-pentadiene, ...

Embodiment 1

[0049] Preparation of Neodymium Trifluoromethanesulfonate

[0050] In the reactor, according to the molar ratio of neodymium oxide and trifluoromethanesulfonic acid, neodymium oxide is added to the trifluoromethanesulfonic acid solution at a ratio of 10:1, heated to 70° C. under stirring conditions, reacted for 8 hours, filtered, and The unreacted neodymium oxide is removed, the aqueous solution of neodymium trifluoromethanesulfonate is concentrated, and then the concentrated aqueous solution of neodymium trifluoromethanesulfonate is placed at room temperature to naturally precipitate crystals, which is neodymium trifluoromethanesulfonate with crystal water.

Embodiment 2

[0052] Preparation of Lanthanum Trifluoromethanesulfonate

[0053] In the reactor, according to the molar ratio of lanthanum oxide and trifluoromethanesulfonic acid, lanthanum oxide is added to the trifluoromethanesulfonic acid solution at a ratio of 10:1, heated to 80° C. under stirring conditions, reacted for 8 hours, filtered, and Remove the unreacted lanthanum oxide, concentrate the aqueous solution of lanthanum trifluoromethanesulfonate, and then place the concentrated aqueous solution of lanthanum trifluoromethanesulfonate at room temperature to naturally precipitate crystals, which is lanthanum trifluoromethanesulfonate with crystal water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com