Preparation method of butadiene/1,3-pentadiene random copolymer

A random copolymer, pentadiene technology, applied in the field of preparation of butadiene/1,3-pentadiene random copolymer, can solve the problem of wide molecular weight distribution, butadiene and isoprene copolymer high molecular weight issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method of butadiene / 1,3-pentadiene copolymer, comprising:

[0019] In an anhydrous and oxygen-free atmosphere, add a quantitative amount of butadiene and 1,3-pentadiene cyclohexane solution (concentration is 10-15g monomer / 100ml cyclohexane ), add a measured random additive, shake well, then add a measured organic alkali metal initiator, and react at 30°C to 90°C. After the polymerization is completed, use 2,6-di-tert-butyl p- The methanol solution of cresol terminated the reaction, and after the solvent was removed, it was dried in a vacuum oven at 50°C.

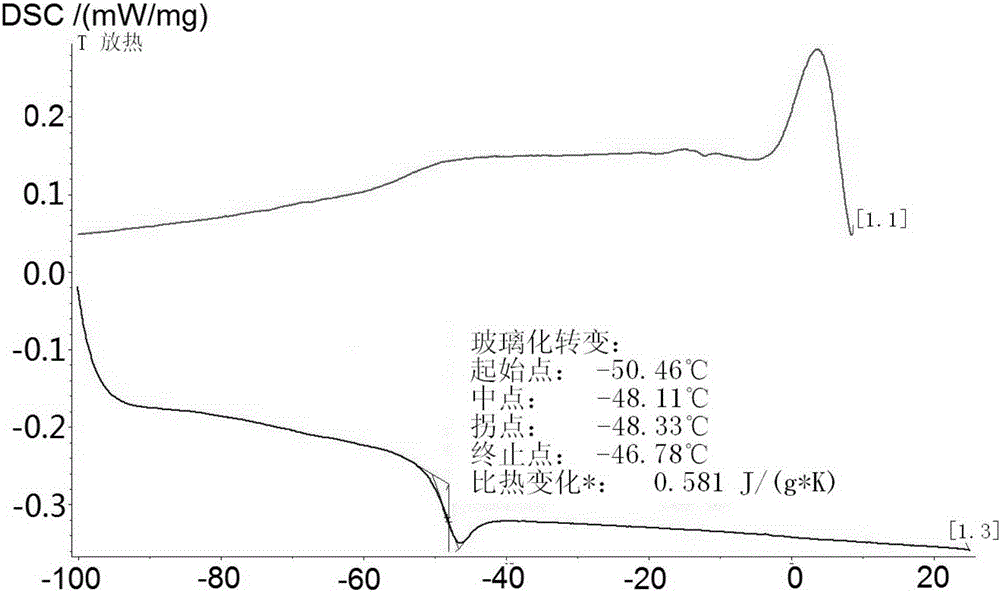

[0020] In the present invention, the microstructure of the synthesized polymer adopts the nuclear magnetic instrument of the model INOVA-400 produced by U.S. Varian Company to measure, and the frequency is 400MHz, with tetramethylsilane (TMS) as the internal standard, and the solvent is CDCl 3 . Infrared analysis was carried out using an infrared instrument of the type IRAffinity-1 produced by Shimadz...

Embodiment 1

[0034] Add the mixed monomer of butadiene and 1,3-pentadiene with a mass ratio of 1:9 to the absorption bottle of cyclohexane (the monomer concentration is 10g / 100ml cyclohexane), and measure 5g of the mixed monomer , and then add a specific amount of randomizing additive a to satisfy n SDS =0.012mmol, finally add 0.12mmol of n-butyllithium (n-BuLi) (the molar ratio of SDS to n-BuLi is 0.1), put the solution into the schlenk reactor and rapidly raise the temperature to 50°C, and polymerize at 50°C for 3-5 Hour. After cooling, stop the reaction with a methanol solution containing 1 wt% 2,6-di-tert-butyl-p-cresol, then precipitate the polymer with excess methanol, wash it repeatedly for 4-5 times, and finally dry it in vacuum at 40°C for 24 hours.

[0035] The calculated polymer yield by weighing is 98%, and the number-average molecular weight of the polymer measured by GPC is 39,000g / mol; the molecular weight distribution is 1.2; 1 H-NMR and IR determined that the 1,4-PB% in ...

Embodiment 2

[0038] Butadiene and 1,3-pentadiene mixed monomers with a mass ratio of 2:8 are added to the absorption bottle of n-hexane (the monomer concentration is 10g / 100ml n-hexane), and the mixed monomers of 5g are measured, and then Add a specific amount of randomizing additive b to satisfy n SDS =0.024mmol, finally add 0.12mmol lithium diisopropylamide (N-Li) (the molar ratio of SDS to N-Li is 0.2), put the solution into the schlenk reactor and rapidly raise the temperature to 60°C, and polymerize at 40°C for 2 ~4 hours. After cooling, stop the reaction with a methanol solution containing 1 wt% 2,6-di-tert-butyl-p-cresol, then precipitate the polymer with excess methanol, wash it repeatedly for 4-5 times, and finally dry it in vacuum at 40°C for 24 hours.

[0039] The calculated polymer yield by weighing is 99%, and the number-average molecular weight of the polymer measured by GPC is 41,000g / mol; the molecular weight distribution is 1.3; 1 H-NMR and IR determined that the 1,4-PB%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com