Preparation method of acrylonitrile-styrene-acrylate tough resin based on block copolymer

A block copolymer, polybutyl acrylate technology, applied in the field of ASA resin materials, can solve the problems of harsh reaction conditions, small range of monomers, and inability to synthesize block copolymers, etc., and achieve fast polymerization reaction and excellent mechanical properties , Molecular weight growth controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

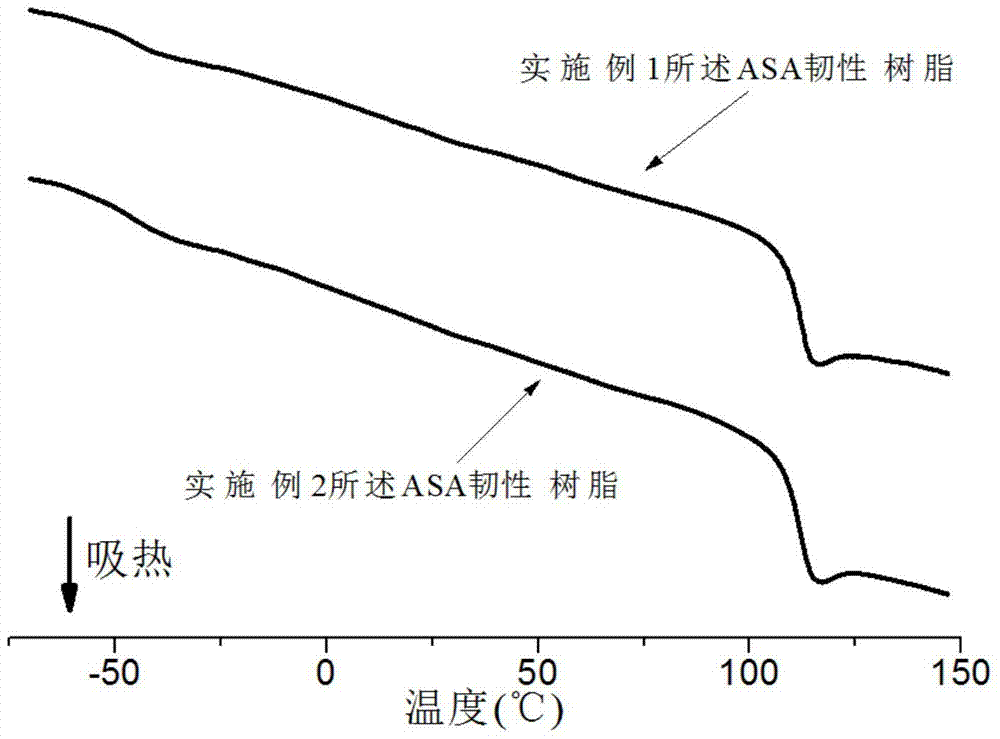

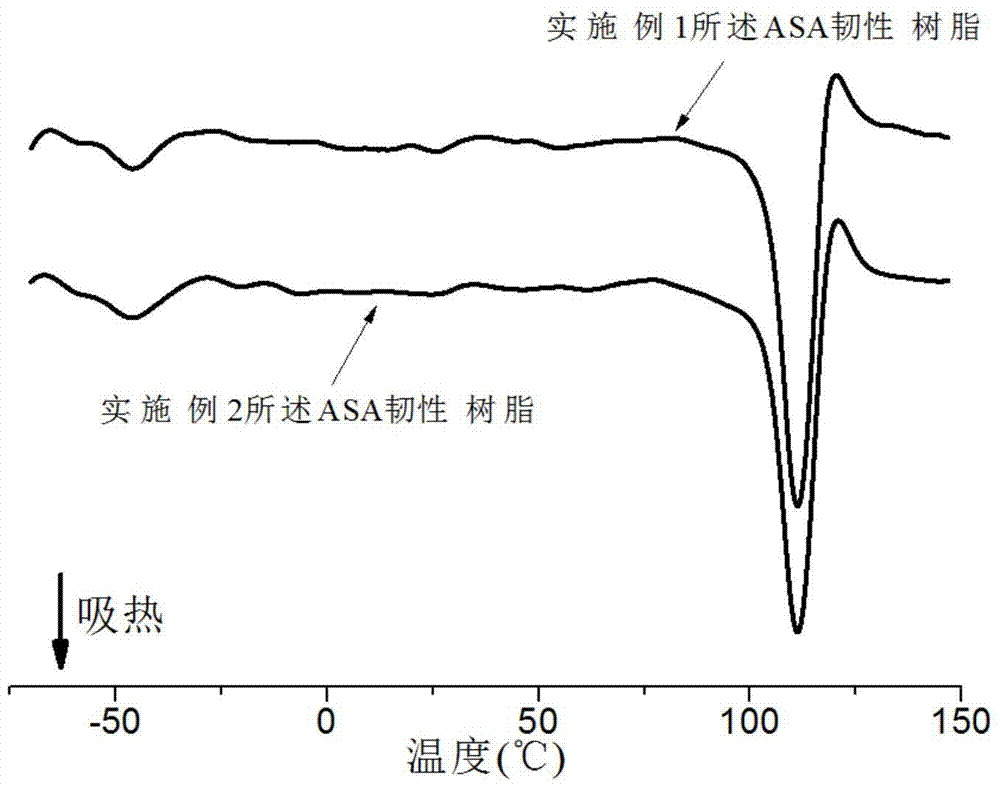

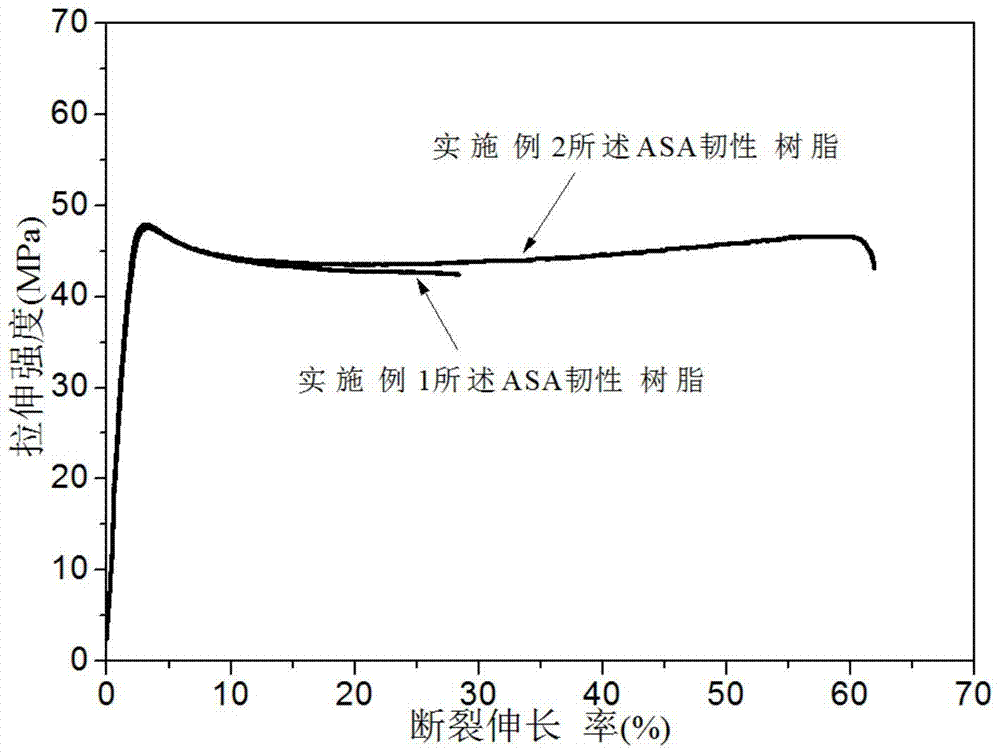

[0055] Block copolymer toughening modifier: R-AA n1 -b-St n2 -b-(St-co-AN) n3 -b-nBA n4 -X, where (St-co-AN) n3 -b-nBA n4 The designed molecular structure of the block copolymer is 30K-120K, and the monomer mass ratio of St to AN is 3:1:

[0056] (1) 1.7 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 80 parts by weight of water to form an aqueous phase, and then mixed with oil composed of 15 parts by weight St and 5 parts by weight AN Pour the phases together into the reactor and stir to mix. Raise the reaction temperature to 70°C, keep stirring, pass nitrogen to remove oxygen for more than 5 minutes, add 0.04 parts by weight of water-soluble initiator potassium persulfate, and polymerize for 1 hour to obtain R-AA n1 -b-St n2 -b-(St-co-AN) n3 -X block copolymer, the block copolymer is stably dispersed in water in the form of particles to form latex.

[0057] (2) After the first st...

Embodiment 2

[0062] Block copolymer toughening modifier: R-AA n1 -b-St n2 -b-(St-co-AN) n3 -b-nBA n4 -b-(St-co-AN) n5 -X, where (St-co-AN) n3 -b-nBA n4 -b-(St-co-AN) n5 The designed molecular structure of the block copolymer is 30K-120K-30K, and the monomer mass ratio of St to AN is 3:1:

[0063] (1) 1.7 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 80 parts by weight of water to form an aqueous phase, and then mixed with oil composed of 15 parts by weight St and 5 parts by weight AN Pour the phases together into the reactor and stir to mix. Raise the reaction temperature to 70°C, keep stirring, pass nitrogen to remove oxygen for more than 5 minutes, add 0.04 parts by weight of water-soluble initiator ammonium persulfate, and polymerize for 1 hour to obtain R-AA n1 -b-St n2 -b-(St-co-AN) n3 -X block copolymer, the block copolymer is stably dispersed in water in the form of particles to form ...

Embodiment 3

[0072] Block copolymer toughening modifier: R-AA n1 -b-St n2 -b-(St-co-AN) n3 -b-nBA n4 -b-(St-co-AN) n5 -X, where (St-co-AN) n3 -b-nBA n4 -b-(St-co-AN) n5 The designed molecular structure of the block copolymer is 30K-120K-30K, and the monomer mass ratio of St to AN is 3:1:

[0073] (1) 1.7 parts by weight of amphiphilic macromolecular reversible addition fragmentation chain transfer reagent (1) was stirred and dissolved in 80 parts by weight of water to form an aqueous phase, and then mixed with oil composed of 15 parts by weight St and 5 parts by weight AN Pour the phases together into the reactor and stir to mix. Raise the reaction temperature to 70°C, keep stirring, pass nitrogen to remove oxygen for more than 5 minutes, add 0.04 parts by weight of water-soluble initiator 4,4'-azobis(4-cyanovaleric acid), and polymerize for 1 hour, get R-AA n1 -b-St n2 -b-(St-co-AN) n3 -X block copolymer, the block copolymer is stably dispersed in water in the form of particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com