Catalytic system for synthesizing piperylene petroleum resin and preparation method for piperylene petroleum resin

A technology of petroleum resin and catalytic system, which is applied in the field of preparation of piperylene petroleum resin catalytic system and piperylene petroleum resin, can solve the problems of reduced catalyst system activity, unstable production process, and high chlorine content of resin, and achieves Good compatibility, low Z-average molecular weight, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

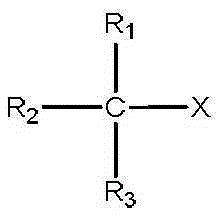

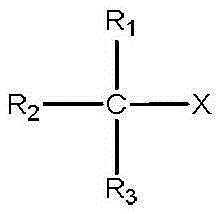

Method used

Image

Examples

Embodiment 1

[0032] The mixture 500g of C5 diolefins and C5 monoolefins obtained by separation of petroleum cracking by-products, the weight ratio of C5 diolefins and C5 monoolefins is 0.68, add 0.5g chloro-tert-butane (0.1wt%) and 0.15g acetone (DN =17.0, the molar ratio of acetone and chloro-tert-butane is 0.5), and diluted to 60wt% with toluene to obtain the first mixture.

[0033] Replace the 2L reactor with stirring with nitrogen, add 100g of toluene and 5.0g of powdered aluminum trichloride, then heat the reactor, when the temperature rises to 50-60°C, start adding the first mixture with a metering pump, the first The mixture was fed at a rate of 20 g / min and then held at 450 rpm for 2 hours.

[0034] After the reaction, the reaction product was washed with water until the pH of the aqueous solution was neutral, and the catalyst was removed. Remove the water phase through a separatory funnel, move the oil phase to a three-necked flask, heat to 140-150°C at normal temperature and pre...

Embodiment 2

[0044] Chloro-tert-butane add-on is 1.5g (0.3wt%) and acetone (DN=17.0, the mol ratio of acetone and chloro-tert-butane is 0.4) add-on is 0.38g, all the other are identical with embodiment 1, obtain The piperylene petroleum resin has a softening point of 96°C, a Mz of 3100, a molecular weight distribution D of 1.48, and a hue of 2.6 (Gardner).

Embodiment 3

[0046] Replace acetone with ethyl acetate (DN=17.1, the mol ratio of ethyl acetate and chloro-tert-butane is 0.5), and the addition is 0.23g, and all the other contents are the same as in Example 1, and the piperylene petroleum resin obtained softens The point is 98° C., the Mz is 3400, the molecular weight distribution D is 1.53, and the hue is 2.5 (Gardner).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com