High-strength self-healing concrete

A concrete and high-strength technology, applied in the field of building materials, can solve the problems of difficult control of microbial metabolism, poor crack repair effect, poor concrete strength, etc., to improve self-repair ability, prolong repair time, excellent durability and compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

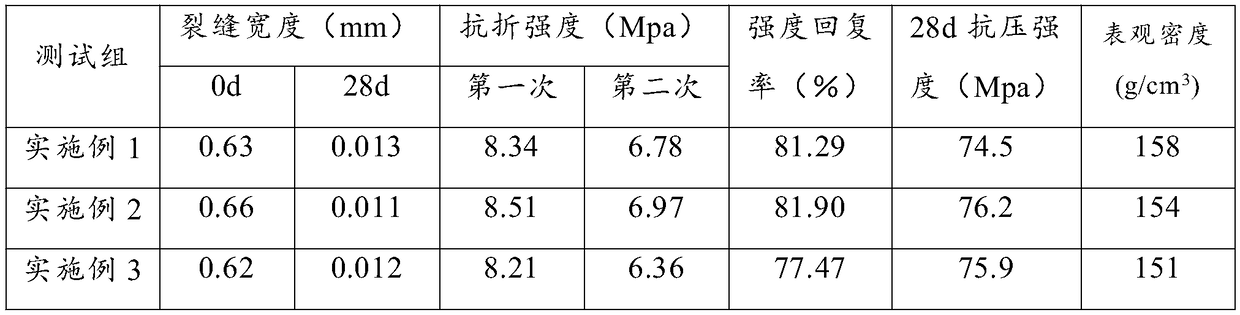

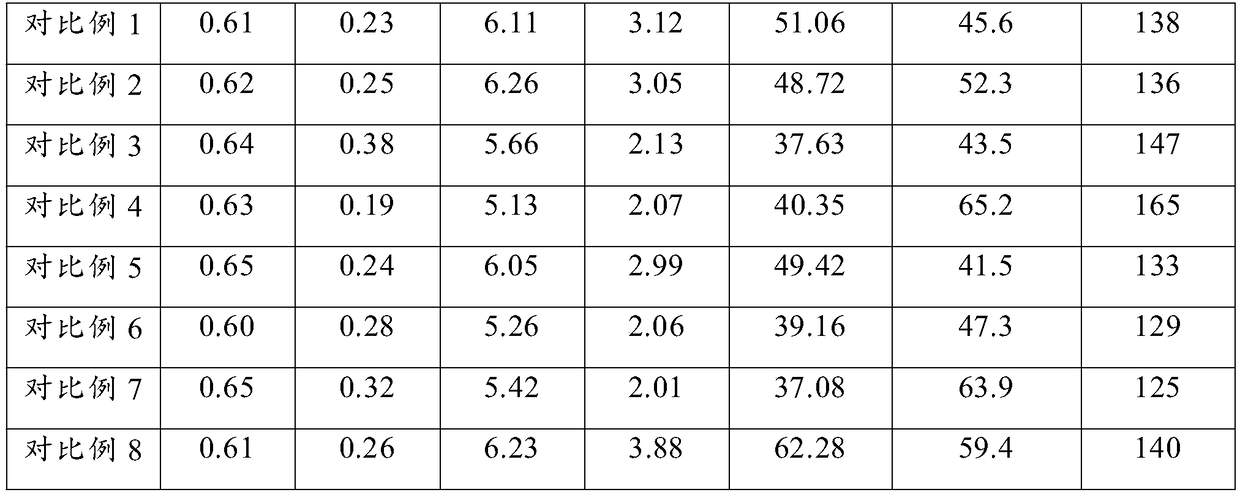

Embodiment 1

[0035] This embodiment provides a kind of high-strength self-healing concrete, and the weight part of raw material of this concrete consists of: Portland cement 100kg, water 30kg, carbon dioxide foaming agent 10kg, dispersant 20kg, aggregate 55kg, microbial compound 20kg , Modified fiber composite 20kg, phenolic antioxidant 1kg, octadecanoic acid 1kg, modified piperylene petroleum resin 4kg.

[0036] It should be noted,

[0037] 1. Dispersant

[0038] The dispersant is composed of guar gum hydroxypropyltrimethylammonium chloride, colloidal silica, diatomaceous earth, silicon carbide powder, fly ash and phenolic resin in a weight ratio of 2:2:8:5:3:10 Composition; The preparation method of described dispersion agent comprises:

[0039] a, 2 parts of guar gum hydroxypropyl trimethylammonium chloride are uniformly dispersed in water by weight, and stirred evenly to obtain solution A, the water content of solution A is 80%;

[0040] b. Evenly disperse 2 parts of colloidal silic...

Embodiment 2

[0062] This embodiment provides a kind of high-strength self-healing concrete, and the weight part of raw material of this concrete is composed of: Portland cement 110kg, water 40kg, carbon dioxide foaming agent 15kg, dispersant 25kg, aggregate 60kg, microbial compound 25kg , Modified fiber composite 25kg, phenolic antioxidant 2kg, octadecanoic acid 2kg, modified piperylene petroleum resin 6kg.

[0063] The preparation method of each raw material and concrete in embodiment 2 is exactly the same as embodiment 1.

Embodiment 3

[0065] This embodiment provides a high-strength self-healing concrete. The raw materials of the concrete are composed in parts by weight of: Portland cement 120kg, water 50kg, carbon dioxide foaming agent 20kg, dispersant 30kg, aggregate 65kg, microbial composite 30kg , Modified fiber composite 30kg, phenolic antioxidant 3kg, octadecanoic acid 3kg, modified piperylene petroleum resin 8kg.

[0066] The preparation method of each raw material and concrete in embodiment 2 is exactly the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com