Method for preparing polymer-grade piperylene

A technology for crude piperylene and pentadiene, which is applied in the field of refining and separating polymerization grade piperylene, can solve the problems of difficulty in realizing stable industrial operation, easy deactivation of adsorbents, etc., and achieves low energy consumption and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

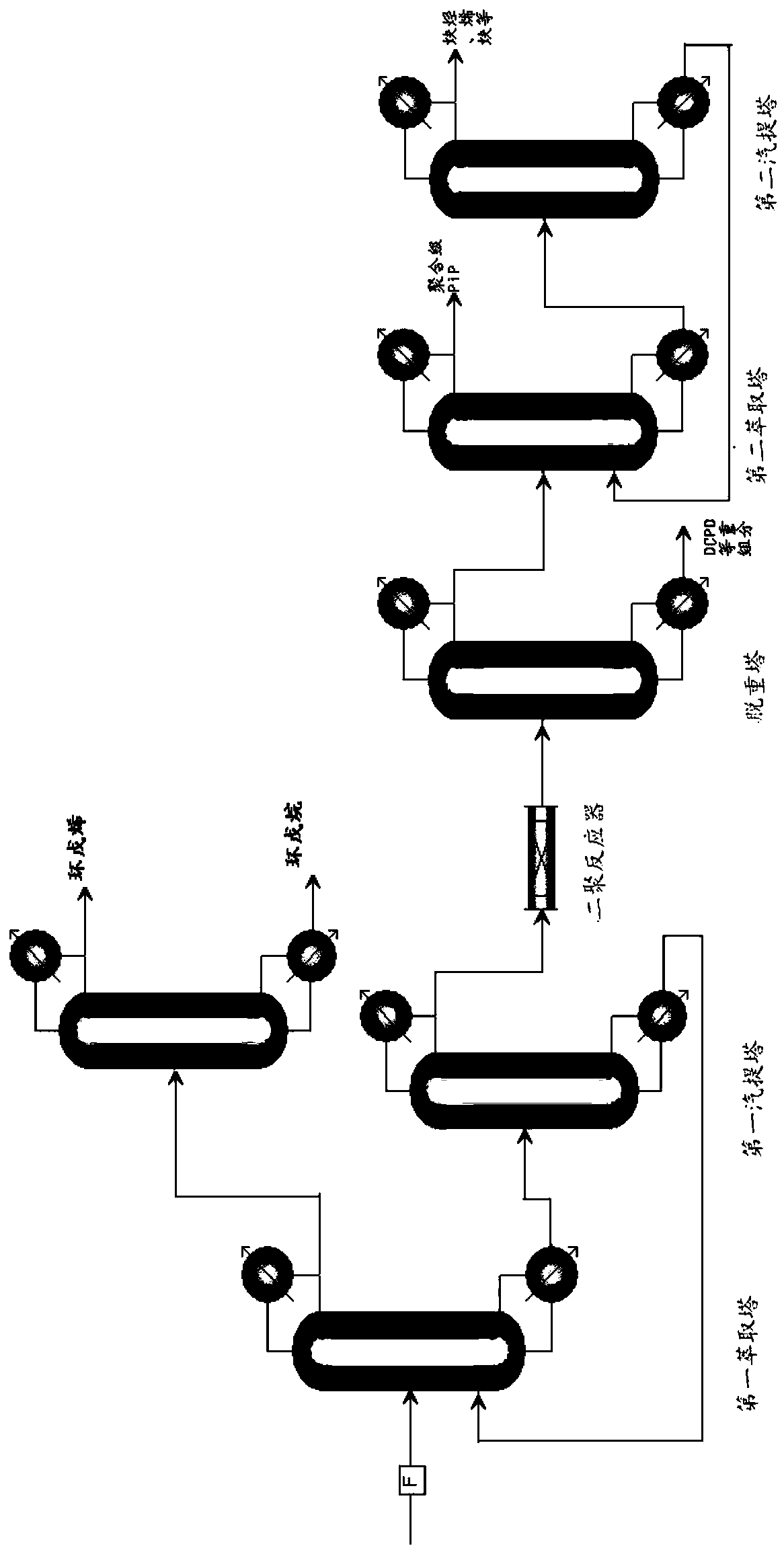

Method used

Image

Examples

Embodiment 1

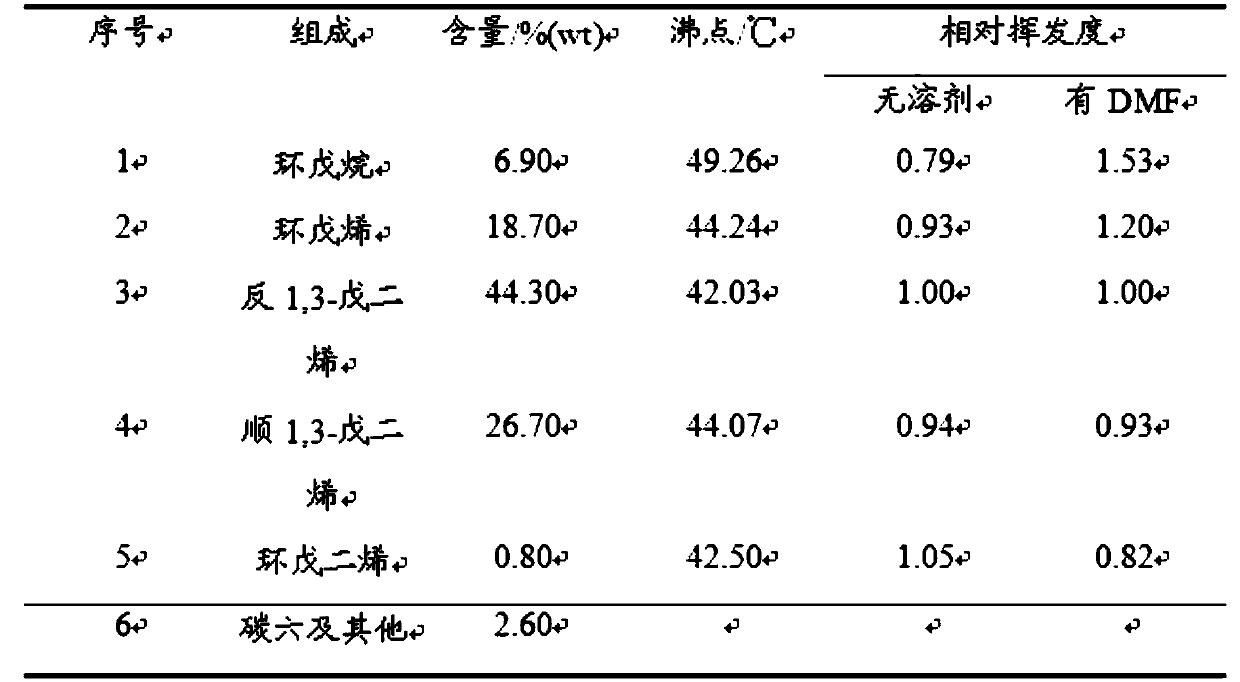

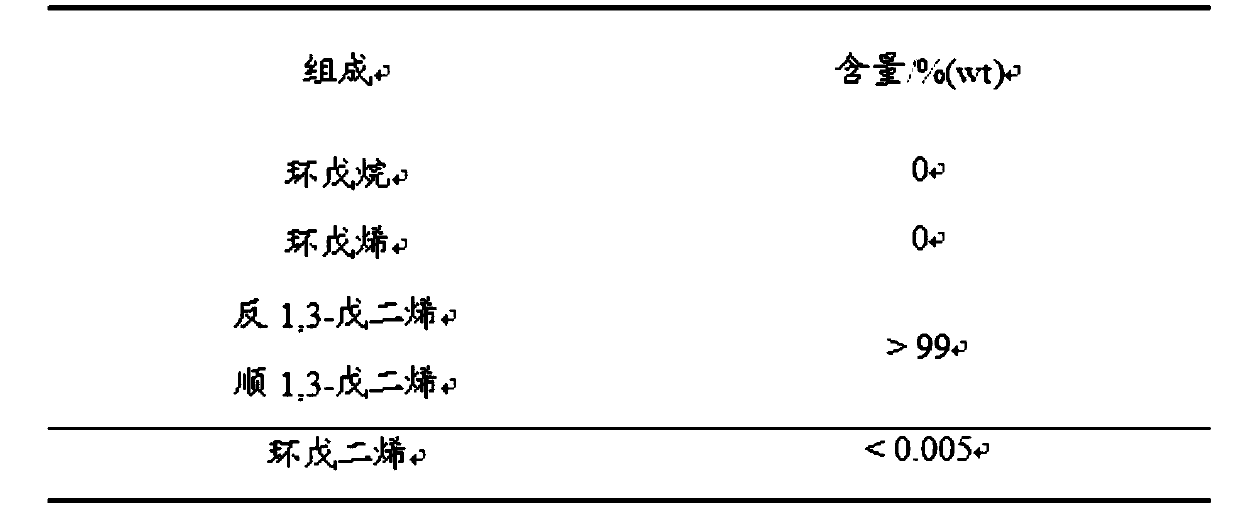

[0032] The crude piperylene raw material enters the first extraction tower in the presence of a polymerization inhibitor, the operating pressure is normal pressure, the temperature of the tower tank is 70°C, and the extractant dimethylformamide is preheated to 40°C and added from the top of the tower, and the crude The pentadiene raw material weight ratio is 6:1, and the reflux ratio is 2, and the mixture material enriched in cyclopentene and cyclopentane is obtained at the top of the tower, and the material enriched in piperylene and extractant is obtained in the tower still; The top material of the first extraction tower enters the rectification tower, the operating pressure is normal pressure, the temperature of the tower bottom is 50°C, the temperature of the top of the tower is 35°C, and the reflux ratio is 5, cyclopentene is obtained from the top of the tower, and cyclopentane is obtained from the bottom of the tower; The material in the bottom of the first extraction tow...

Embodiment 2

[0034]The crude piperylene raw material enters the first extraction tower in the presence of a polymerization inhibitor, the operating pressure is 0.2MPa, the temperature of the bottom of the tower is 150°C, and the extraction agent dimethylformamide is preheated to 100°C and added from the top of the tower, and the crude The pentadiene raw material weight ratio is 20:1, and the reflux ratio is 30, and the mixture material enriched in cyclopentene and cyclopentane is obtained at the top of the tower, and the material enriched in piperylene and extractant is obtained in the tower still; The top material of the first extraction tower enters the rectification tower, the operating pressure is normal pressure, the temperature of the tower bottom is 60°C, the temperature of the top of the tower is 45°C, and the reflux ratio is 50, cyclopentene is obtained from the top of the tower, and cyclopentane is obtained from the bottom of the tower; The material in the bottom of the first extr...

Embodiment 3

[0036] The crude piperylene raw material enters the first extraction tower in the presence of a polymerization inhibitor, the operating pressure is 0.1MPa, the temperature of the bottom of the tower is 110°C, and the extraction agent dimethylformamide is preheated to 70°C and added from the top of the tower. The pentadiene raw material weight ratio is 13:1, and the reflux ratio is 16, and the mixture material enriched in cyclopentene and cyclopentane is obtained at the top of the tower, and the material enriched in piperylene and extractant is obtained in the tower still; The top material of the first extraction tower enters the rectification tower, the operating pressure is normal pressure, the temperature of the tower bottom is 55°C, the temperature of the top of the tower is 40°C, and the reflux ratio is 28, cyclopentene is obtained from the top of the tower, and cyclopentane is obtained from the bottom of the tower; The material in the bottom of the first extraction tower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com