Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

A technology of dicyclopentadiene and maleic anhydride, which is applied in the new field of copolymerization of dicyclopentadiene and maleic anhydride, can solve problems such as narrow particle size distribution, and achieve narrow particle size distribution, easy process control, and controllable appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

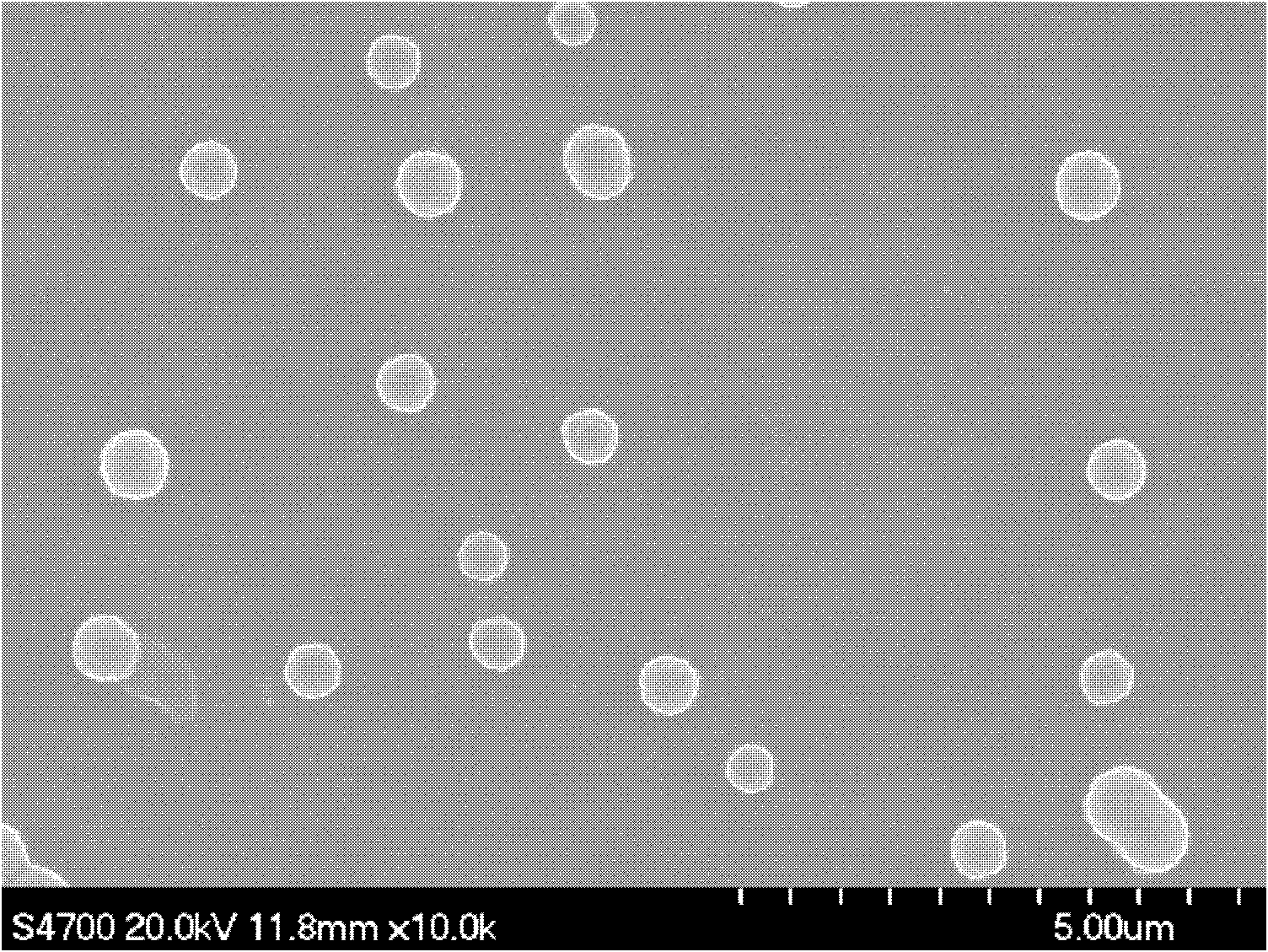

[0047] The molar ratio of MAn and DCPD is 1:1, in which MAn is 1.2255g and DCPD is 1.6525g; the initiator is AIBN, 0.0328g; the medium is ethyl benzoate and n-hexane, each 25mL. Heated in a water bath and reacted for 6 hours at a temperature of 70°C to obtain DCPD / MAn copolymer microspheres, the average particle diameter (Dn), dispersion coefficient (U) and polymerization conversion rate (C p ), and the number average molecular weight of the polymer The results are shown in Table 1. Scanning electron micrographs of polymer microspheres are shown in figure 1 .

Embodiment 2

[0049] The molar ratio of MAn and DCPD is 1:1, in which MAn is 1.2255g and DCPD is 1.6525g; the initiator is AIBN, 0.0328g; the medium is ethyl formate and n-hexane, each 25mL. Heated in a water bath and reacted for 6 hours at a temperature of 70°C to obtain DCPD / MAn copolymer microspheres, the average particle diameter (Dn), dispersion coefficient (U) and polymerization conversion rate (C p ), and the number average molecular weight of the polymer The results are shown in Table 1.

Embodiment 3

[0051] The molar ratio of MAn and DCPD is 1:1, in which MAn is 1.2255g and DCPD is 1.6525g; the initiator is AIBN, 0.0328g; the medium is ethyl acetate and n-hexane, each 25mL. Heated in a water bath and reacted for 6 hours at a temperature of 70°C to obtain DCPD / MAn copolymer microspheres, the average particle diameter (Dn), dispersion coefficient (U) and polymerization conversion rate (C p ), and the number average molecular weight of the polymer The results are shown in Table 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com