Lost foam casting type composite wear-resistant component and casting method thereof

A technology of composite wear-resistant parts and lost foam casting, applied in the field of lining plates and roller sleeves, can solve the problems of insufficient strength of prefabricated bodies, long production cycle, low yield of finished products, etc., to save costs, increase efficiency, environmental pollution, production The effect of short cycle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] As another preferred embodiment, the composite wear-resistant member is a lining plate or a roller sleeve of a coal mill.

[0046] The preferred modes of the above composite wear parts can be freely combined.

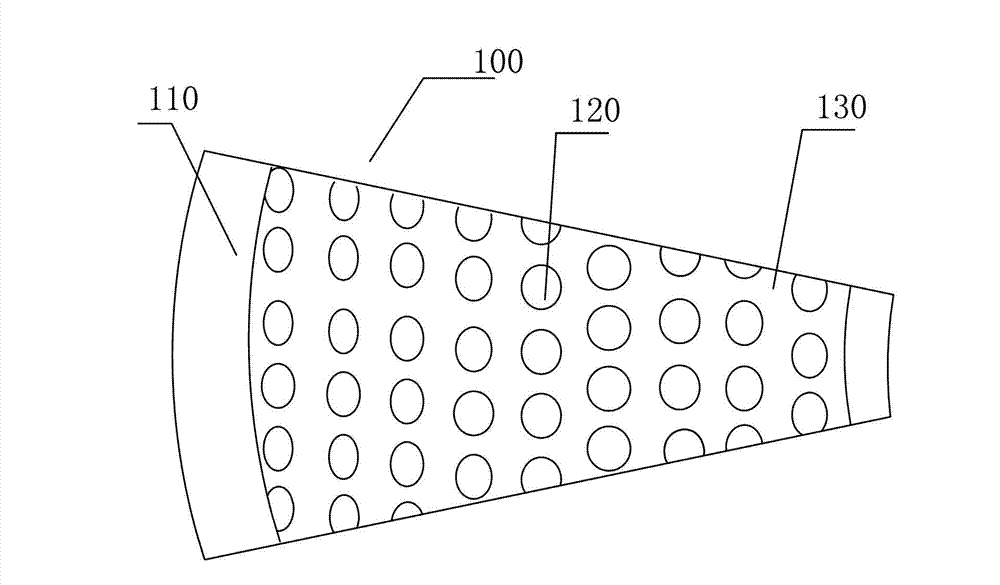

[0047] The lost foam used for casting the above-mentioned composite wear parts, its shape is consistent with the shape of the finished wear parts, including the lost foam matrix with a concave part and a plurality of lost foam columns evenly arranged in the concave part, each lost foam column is There is a certain gap in between.

[0048] As a preferred embodiment, the specifications of the lost foam columns are φ30mm×height 35mm or φ28mm×height 30mm, the lost foam columns are vertically arranged in the concave portion, and the gaps between the lost foam columns are filled with reinforcing particles. The required vacancies, more preferably, the percentage of the total volume of the voids between the lost foam pillars to the total volume of the concave portion is...

Embodiment 1

[0051] Example 1 Lost Foam Casting Composite Wear-Resistant Ceramic Liner 1, Lost Foam 100 for Casting Liner 1 and Casting Method for Liner 1

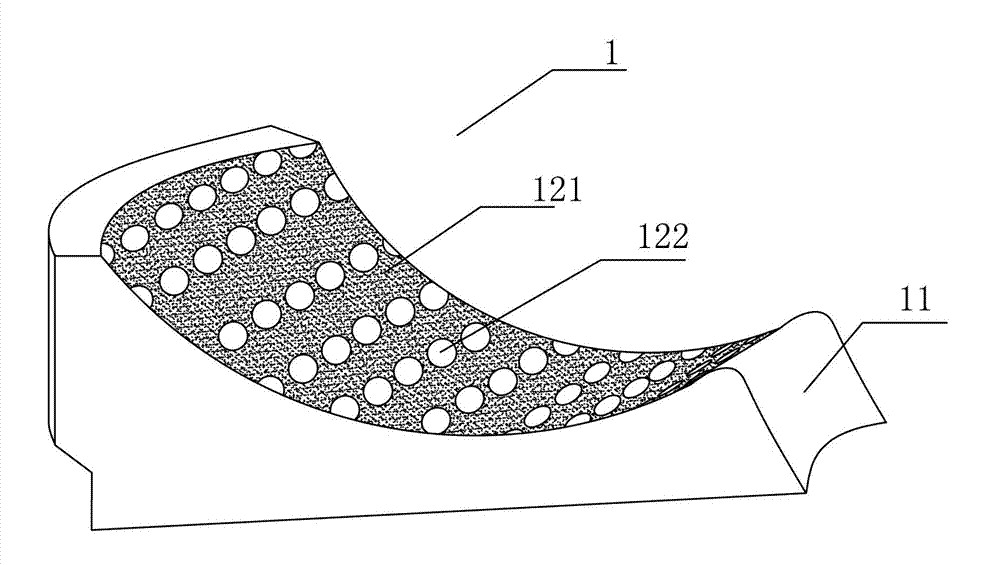

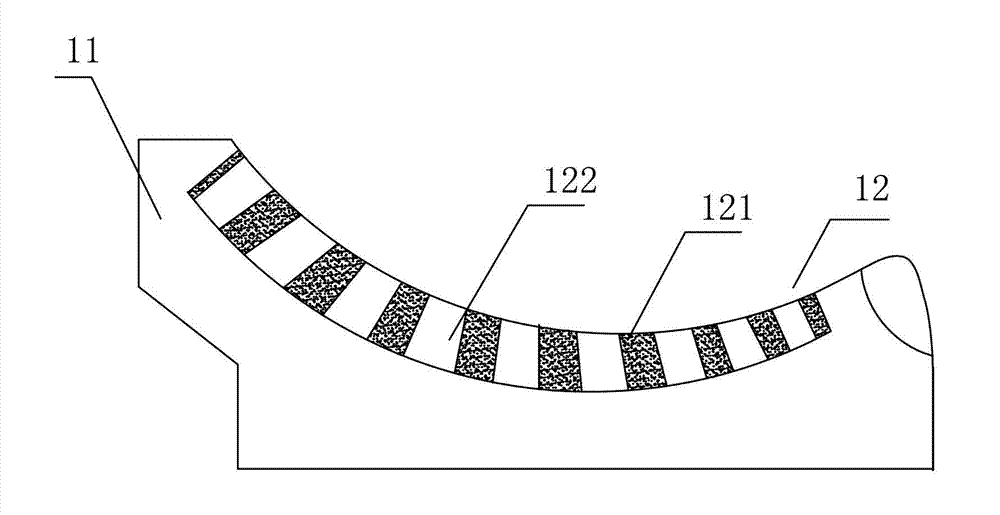

[0052] In this example, the composite wear-resistant ceramic lining plate 1 for the ZGM medium-speed coal mill is prepared: the structure of the cast lining plate 1 is shown in figure 1 and figure 2 , which is composed of a metal base part 11 with a concave part, and a ceramic working layer part 12 which is integrally cast with the metal base part 11 and filled in the concave part. The working layer part is uniformly distributed with ceramic particles 121. The ceramic particles 121 are fixed on the ceramic working layer part 12 by the solidification of the molten metal flowing around the ceramic particles 121 during the integral casting.

[0053] The material of the ceramic particles is zirconia toughened aluminum oxide (wherein, the content of zirconia is 46-60 (weight)%, and the content of aluminum oxide is 40-54 (weight)%; 1.2mm,...

Embodiment 2

[0062] Example 2 Lost foam casting composite wear-resistant ceramic roll cover 2, lost foam 200 for casting roll cover 2 and casting method of roll cover 2

[0063] Lost foam casting composite wear-resistant ceramic roll sleeve 2: see Figure 5 (finished roll sleeve) and Image 6 (The internal structure of one of the ceramic working layers after the surface of the finished roller sleeve is polished), which consists of a metal base part 21 with a plurality of concave parts on the surface, and a plurality of metal base parts 21 integrally cast with the metal base part 21 and filled in the plurality of concave parts. Each ceramic working layer is composed of 22 ceramic working layers. Ceramic particles 221 are evenly distributed in each ceramic working layer. The ceramic particles 221 are fixed on each ceramic working layer by being wrapped and solidified by the molten metal flowing around the ceramic particles 221 during the integral casting. Layer portion 22 .

[0064] The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com