Rolling method for applying pulse current to metal composite plate

A metal composite plate and pulse current technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of small size of metal composite plate, difficult to meet user needs, large energy consumption, etc., to improve metal Plasticity, improving bonding strength and production efficiency, and reducing the effect of critical reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Taking copper / aluminum bimetal composite as an example, the preparation method is as follows:

[0036] The material selection is an industrial pure copper plate with a size of 200mm×50mm×2mm and a pure aluminum plate with a size of 200mm×50mm×8mm. The pure copper plate and pure aluminum plate are ground and polished, and the surface of the plate is cleaned with acetone;

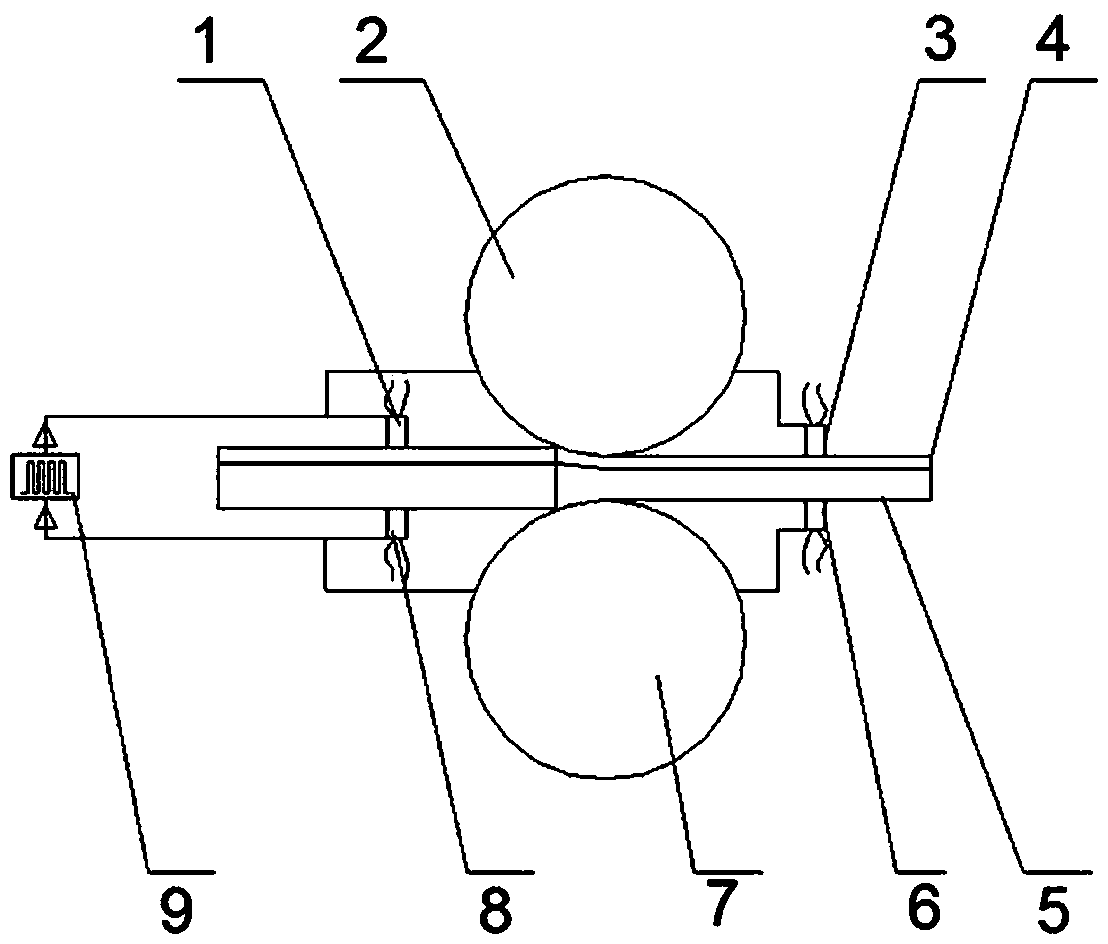

[0037] Rolling was carried out on a two-roll mill with equal roll speed and equal roll diameter (roll length 350mm, roll diameter 320mm, rolling speed 0.1m / s).

[0038] Turn on the pulse power supply 9, and the pulse peak current density is 150A / mm when applied to the sheet metal processing section 2 .

[0039] Start the rolling mill, make the upper and lower rolls of the rolling mill reversely rotate at a certain speed, and use the push plate to send the slab into the middle of the rotating upper roll 2 and the lower roll 7.

[0040] figure 1 Shown is a schematic diagram of a current loop implementat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com