Biaxially-oriented polypropylene capacitance film resisting high temperature and preparation method thereof

A technology of biaxial stretching and polypropylene, applied in the field of BOPP insulating film and its preparation, can solve the problems of unfavorable performance of PP capacitor film, achieve high industrial application value, improve heat resistance and breakdown strength, and be simple and easy to realize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

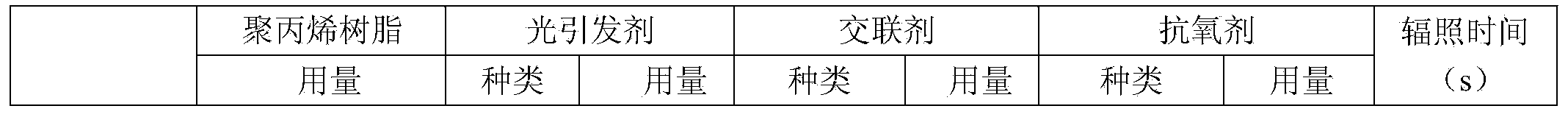

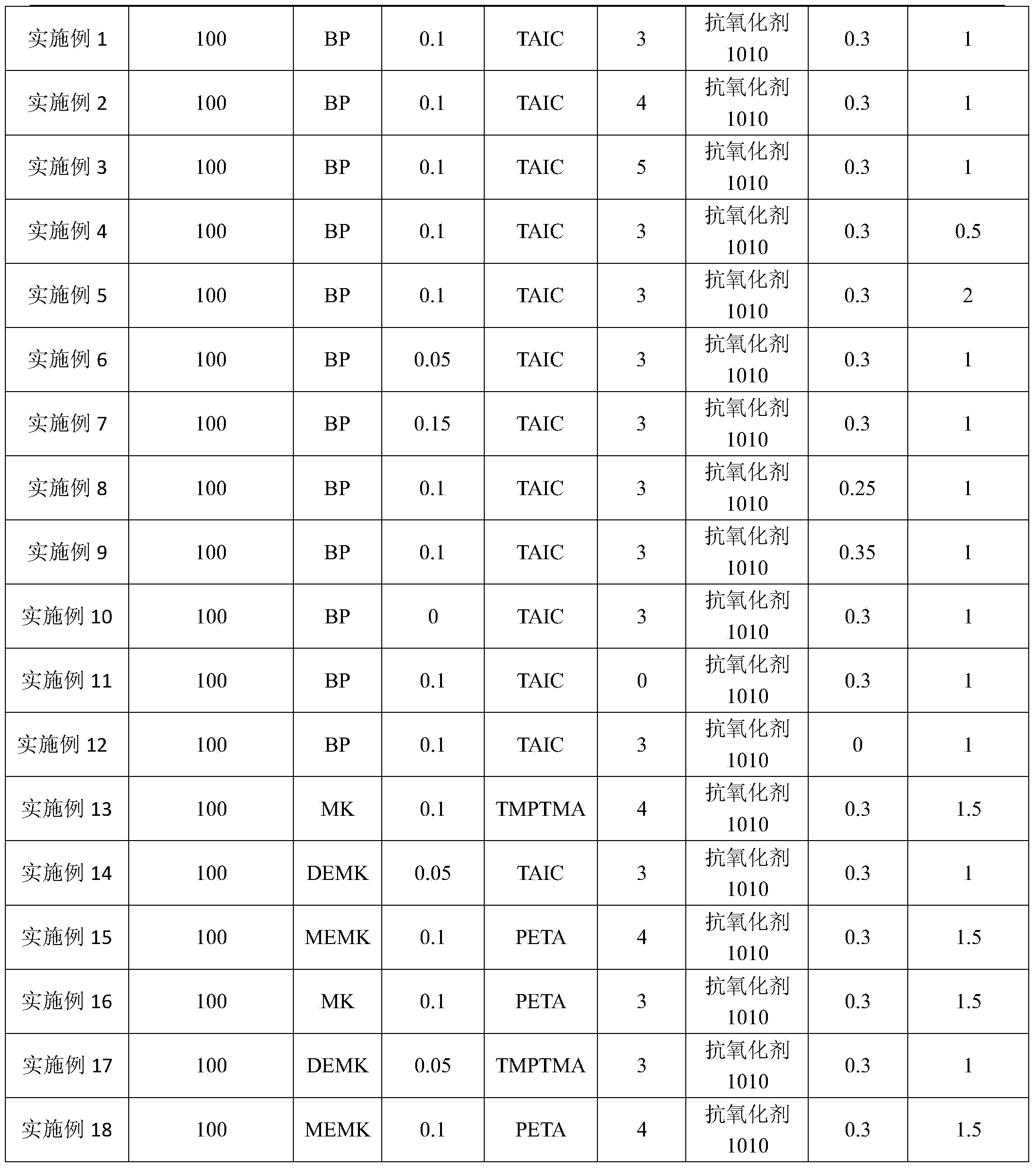

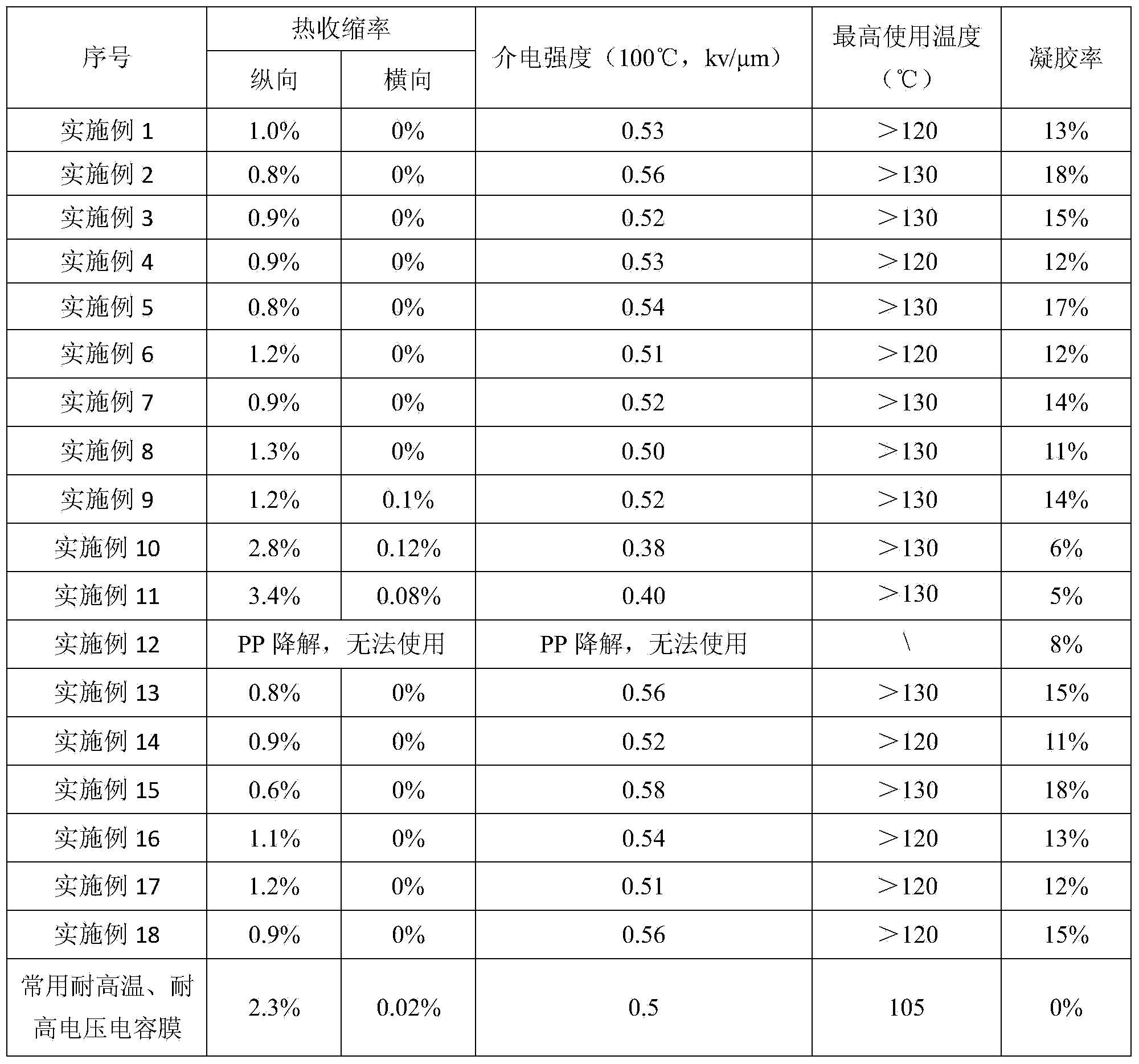

Examples

Embodiment Construction

[0020] In one embodiment of the present invention, in the polypropylene raw material composition in step (1), the polypropylene resin adopts an isotacticity of 96%-97%, a melt flow index of 2.1-3.5g / 10min, a molecular weight distribution of Mw / Mn=7~9, polypropylene resin with ash content of 10ppm~20ppm. Test the melt flow index according to GB / T3682-2000 and ASTM D1238-98 standards. Put the raw material to be tested into a small tank, and a thin tube is connected at the end of the tank. The diameter of the thin tube is 2.095mm, and the length of the tube is 8mm. Heating to 190°C, under the pressure of 2.16kg weight applied to the upper end of the raw material, measure the extruded weight of the raw material within 10 minutes, which is the flow index of the plastic, and the unit is g / 10min.

[0021] In one embodiment of the present invention, in the polypropylene raw material composition in step (1), the photoinitiator is a benzil derivative such as diphenyl ethylene diketone o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com