High-energy density polymer composite dielectric and preparation method thereof

A high energy storage density, polymer technology, applied in the field of dielectric materials and energy storage materials preparation, can solve the problems of reduced breakdown strength of composite materials, limitation of energy storage density of composite materials, increase of dielectric loss, etc., to improve dispersion , reduce internal defects, reduce the effect of dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

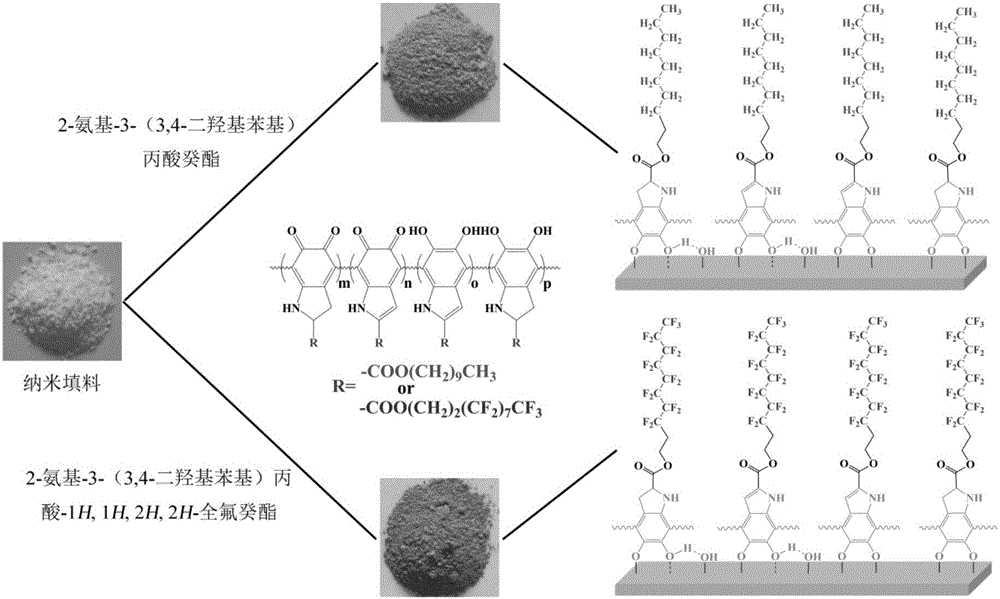

[0044] This embodiment relates to a high energy storage density polymer composite dielectric, the composite material is composed of 97.5% mass fraction of PVDF as a matrix and 2.5% mass fraction of 2-amino-3-(3,4-dihydroxyphenyl) Titanium dioxide nanosheets modified with propionic acid-1H, 1H, 2H, 2H-perfluorodecyl ester were used as fillers. Wherein 2-amino-3-(3,4-dihydroxyphenyl)propionic acid-1H, 1H, 2H, 2H-perfluorodecyl ester modified titanium dioxide nanosheets were prepared by the following steps:

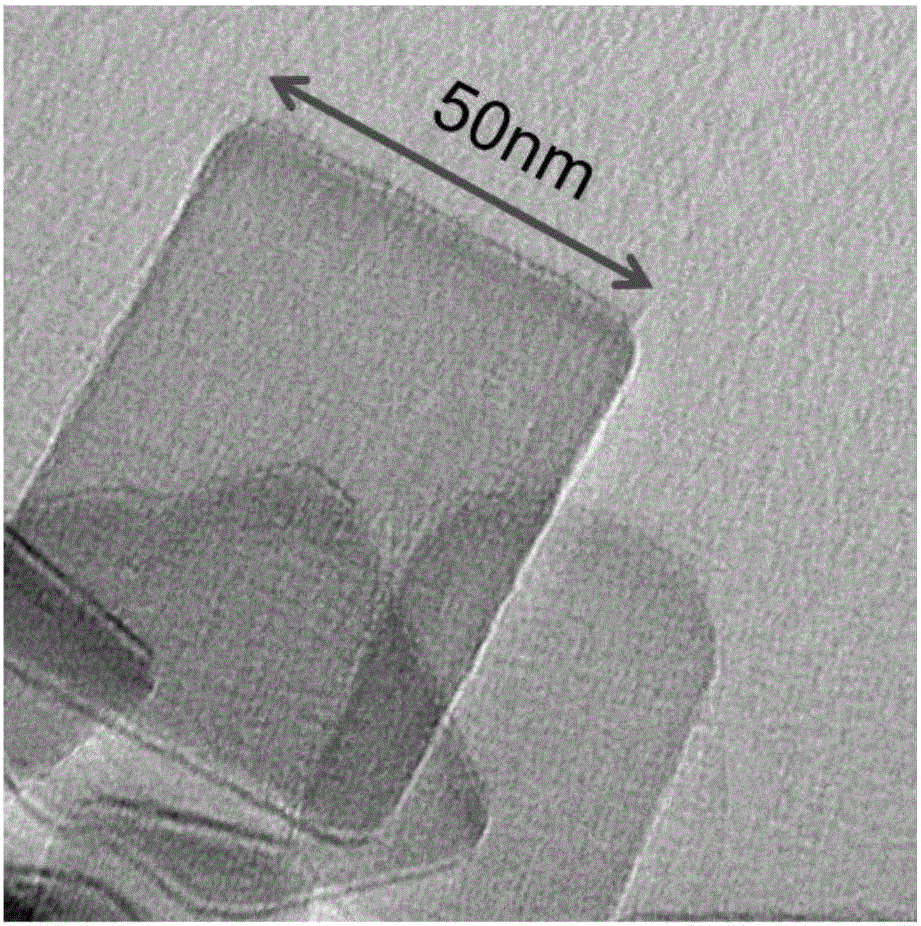

[0045] A. Titanium dioxide nanosheets: synthesized according to the method reported in the literature (X.G.Han, et al., J.Am.Chem.Soc., 2009, 131, 3152.);

[0046] B. Dopamine with long-chain structure: 1H, 1H, 2H, 2H-perfluorodecanol reacts with L-3,4-dihydroxyphenylalanine to obtain 2-amino-3-(3,4-dihydroxyl Phenyl)propionic acid-1H,1H,2H,2H-perfluorodecyl ester. This long-chain structure of dopamine was synthesized using the method in the literature (Manolakis, I. et al...

Embodiment 2

[0054] This embodiment relates to a high energy storage density polymer composite dielectric, the composite material is composed of 85% mass fraction of P(VDF-HFP) as a matrix and 15% mass fraction of 2-amino-3-(3,4- The barium titanate nanowires modified with decyl dihydroxyphenyl)propionate were used as fillers. The barium titanate nanowires modified with decyl 2-amino-3-(3,4-dihydroxyphenyl) propionate were prepared through the following steps.

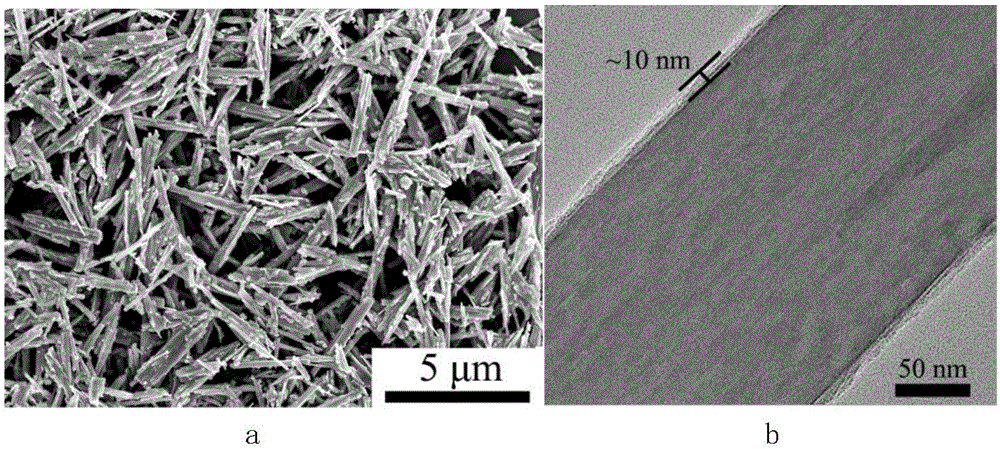

[0055] A, barium titanate nanowires: synthesized according to the method reported in the literature (G.Y.Wang, et al., ACS Applied Materials & Interfaces 2015, 7, 18017);

[0056] B. Dopamine with long-chain structure: 1-decanol reacts with L-3,4-dihydroxyphenylalanine to obtain 2-amino-3-(3,4-dihydroxyphenyl)propionic acid decyl ester. This long-chain structure of dopamine was synthesized using the method in the literature (Manolakis, I. et al., Macromol. Rapid Commun. 2014, 35, 71-76.).

[0057] C. Dopamine-modified barium tita...

Embodiment 3

[0064] This embodiment relates to a high energy storage density polymer composite dielectric, the composite material is composed of 75% mass fraction of P(VDF-TrFE) as a matrix and 25% mass fraction of 2-amino-3-(3,4 -Dihydroxyphenyl) propionate modified copper calcium titanate nanowires as filler composition. Wherein the preparation steps of 2-amino-3-(3,4-dihydroxyphenyl) propionate-modified copper calcium titanate nanowires are the same as those in Example 2, the difference is: the high dielectric constant used The nanofillers are copper calcium titanate nanowires. The synthesis of such copper calcium titanate nanowires adopts the method in the modified literature (H.X.Tang, et al., NanoEnergy 2015, 17, 302-307.).

[0065] The present embodiment also relates to a method for preparing a high energy storage density polymer composite dielectric, the method comprising the following steps:

[0066] Step 1, adding 3.75 g of the fluorine-containing ferroelectric polymer matrix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com