Organic carrier for silver paste and preparation method thereof as well as silver paste containing organic carrier and solar cell manufactured from silver paste

A solar cell and organic carrier technology, applied in the field of solar cells, can solve problems such as high viscosity, lower production efficiency, and affect printing speed, and achieve the effects of simple preparation process, high photoelectric conversion efficiency, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

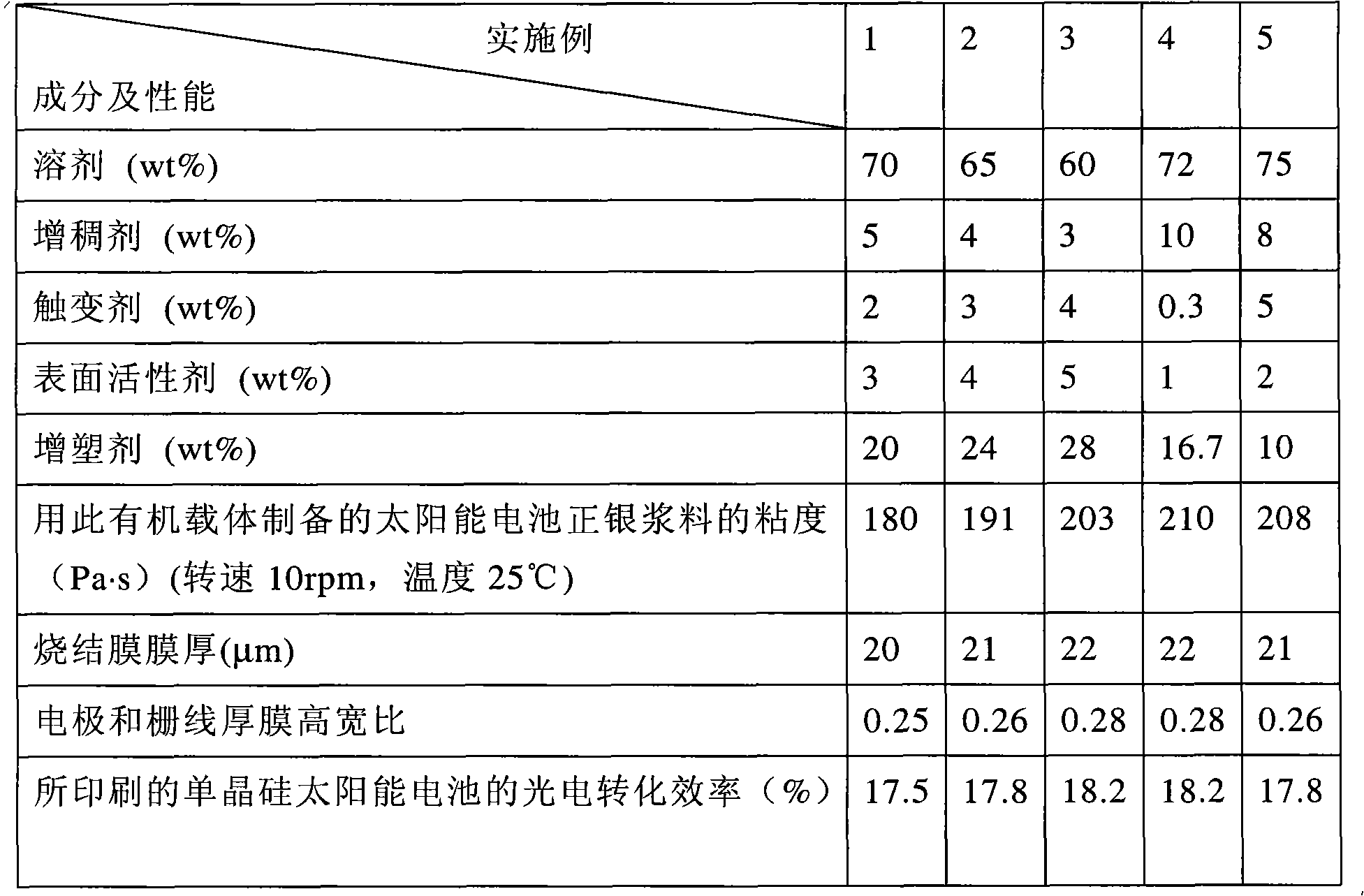

Embodiment 1

[0027] Prepare 100 g of organic vehicle according to the formula in Table 1. Weigh solvent terpineol: 70g, then thickener ethylcellulose: 5g, thixotropic agent hydrogenated castor oil: 2g, surfactant Span 85: 3g, plasticizer dibutyl phthalate: 20 g was added to the solvent, and the mixture was placed in a container and heated in a water bath at 60° C., and stirred at a speed of 60 rpm to completely dissolve it to obtain an organic vehicle. Then with 16wt% organic carrier and 84wt% solid powder (wherein solid powder is the silver powder of 80wt%, the lead borosilicate glass powder of 3wt%, the titanium dioxide additive of 1wt%) is formulated into slurry, and this slurry has suitable Viscosity, the viscosity is 180Pa·s (10rpm, 25°C), excellent printing performance, meeting the high-speed and high-resolution screen printing requirements of 325-mesh stainless steel stencil, using this conductive silver paste to print the conductive silver paste on the battery substrate through Sc...

Embodiment 2

[0030] Prepare 100 g of organic vehicle according to the formula in Table 1. Weigh solvent butyl carbitol: 65g, then thickener ethylcellulose: 4g, thixotropic agent fumed silica: 3g, surfactant lecithin: 4g, plasticizer tributyl citrate: 24g is added in the solvent, heated in a water bath at 60°C, and stirred at a speed of 60 rpm to make it all dissolve, with 16wt% organic carrier and 84wt% solid powder (wherein the solid powder is 80wt% silver powder, 3wt% lead borosilicate glass powder, 1wt% titanium dioxide additive) to prepare a slurry, the slurry has a suitable viscosity, the viscosity is 191Pa s (10rpm, 25 ℃), excellent printing performance, to meet the 325 mesh stainless steel screen According to the high-speed and high-resolution screen printing requirements, use the conductive silver paste on the battery substrate to sinter the conductive silver paste by screen printing to obtain the front electrode and grid line of the solar cell panel, and the solar cell sheet front...

Embodiment 3

[0033] Prepare 100 g of organic vehicle according to the formula in Table 1. Weigh solvent butyl carbitol acetate: 60g, then successively thickener ethylcellulose: 3g, thixotropic agent organic bentonite: 4g, surfactant oleic acid: 5g, plasticizer dibutyl phthalate Esters: 28g is added in the solvent, heated in a water bath at 60°C, and stirred at a speed of 60 rpm to make it all dissolve, use 16wt% organic carrier and 84wt% solid powder (wherein the solid powder is 80wt% silver powder, 3wt% lead borosilicate glass powder, 1wt% titanium dioxide additive) to prepare a slurry, the slurry has a suitable viscosity, the viscosity is 203Pa s (10rpm, 25 ℃), excellent printing performance, to meet 325 mesh stainless steel The high-speed and high-resolution screen printing requirements of the screen, use the conductive silver paste on the battery substrate to sinter the conductive silver paste by screen printing to obtain the front electrode and grid line of the solar cell panel, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com