Abietate alcohol ether type quaternary ammonium salt surface active agent and preparation method thereof

A technology of rosin ester alcohol ether and surfactant, which is applied in the field of functional green surfactant and its preparation, can solve the problem that surfactant is difficult to meet the needs of production and life, and achieve high added value, low product toxicity, Effect of Unique Chemical Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

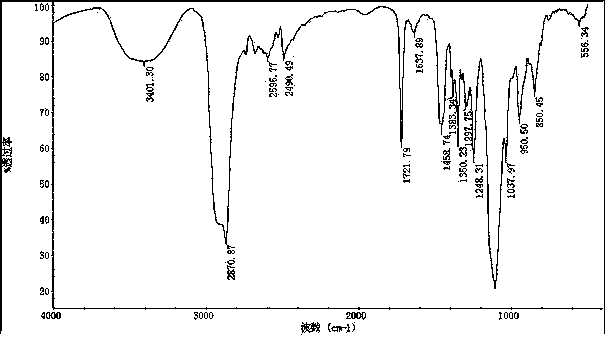

Image

Examples

Embodiment 1

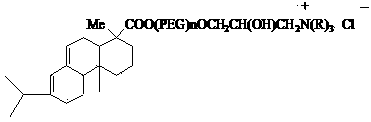

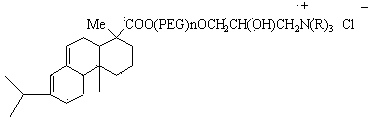

[0021]

[0022] In the formula, the molecular weight n of polyethylene glycol PEG is any one of 200, 400, 600, 1000, 2000, 4000, and in the formula, R is methyl CH 3 , Ethyl CH 2 CH 3 , Ethanol CH 2 CH 2 Any one of OH.

[0023] Example 2

Embodiment 2

[0025] Weigh rosin and polyethylene glycol 400 with a molar ratio of 1:1 and pour them into a 500mL four-necked flask, and then add an appropriate amount of zinc oxide (the amount of zinc oxide accounts for about 0.1-0.2% of the mass of rosin) as a catalyst, Heat to 230-280°C to make it fully react, and when the acid value drops to about 10, the reaction is basically completed, then cool down.

[0026] Then take 0.1 mol of the above reaction product in a 250 mL dry three-necked flask, add 0.1 mol of epichlorohydrin, 0.12 mol of sodium hydroxide (added in 50% aqueous solution), 0.1% of rosin quality tetrabutylammonium bromide and dichloromethane solvent, warming up to 50°C, stirring for 4h, cooling to room temperature and suction filtration. The solid phase was washed twice with dichloromethane, distilled off dichloromethane and a small amount of unreacted epichlorohydrin (around 85°C) to obtain a rosin-based alcohol ether intermediate.

[0027] Add the intermediate synthesize...

Embodiment 3

[0032] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com