Method and device for preparing 6-amino-capronitrile with caprolactam liquid phase method

A technology of caprolactam liquid and aminocapronitrile is applied in the field of preparation of aminocapronitrile, which can solve the problems of high reaction temperature and high energy consumption of gas phase method, and achieve the effects of low reaction temperature, low energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

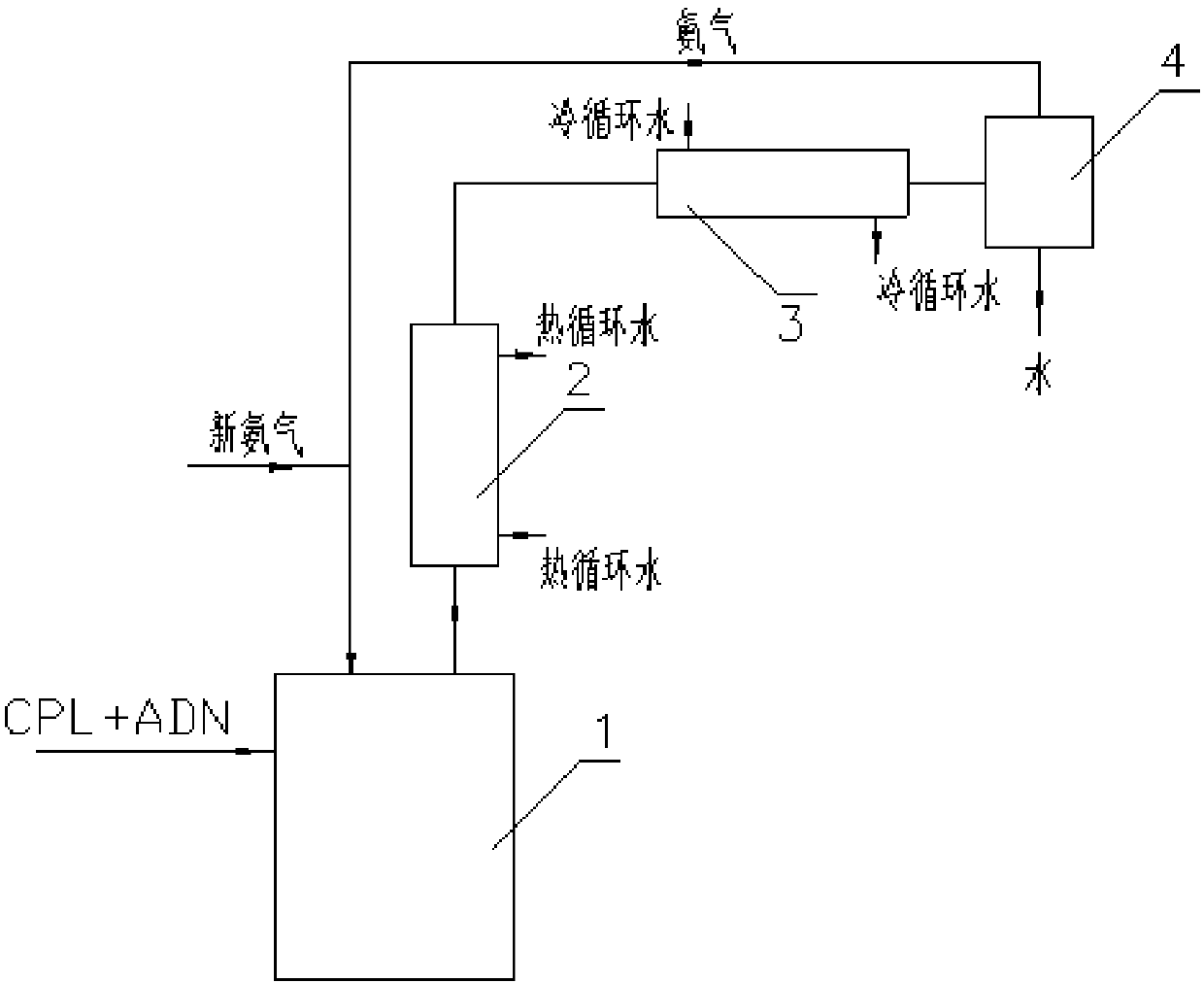

Method used

Image

Examples

Embodiment 1

[0040] Mix 10g of caprolactam, 100g of adiponitrile, and 0.02g of phosphoric acid, and add them into a reaction kettle with an ammonia water separator to stir and heat at a stirring speed of 1000RPM. 2 hours. During the reaction, the mass ratio of ammonia to caprolactam was 5.8:1. After the reaction, the conversion rate of caprolactam was 58%, and the selectivity was 97.8%. The reaction product was subjected to rectification and separation to obtain 6-aminocapronitrile with a purity of 99.1%.

[0041] In this embodiment, when the temperature at the bottom of the vacuum distillation tower is 152° C., the temperature at the top of the tower is 130° C., and the vacuum degree is 2.4 torr, 6-aminocapronitrile is distilled from the top of the tower.

Embodiment 2

[0043] Mix 10g of caprolactam, 100g of adiponitrile, and 0.5g of ammonium phosphate, and add them into a reaction kettle with an ammonia water separator to stir and heat at a stirring speed of 1500RPM. Time 1.5 hours. During the reaction, the mass ratio of ammonia to caprolactam was 10:1. After the reaction, the conversion rate of caprolactam was 65%, and the selectivity was 98.2%. The reaction product was subjected to rectification and separation to obtain 6-aminocapronitrile with a purity of 99.2%.

[0044] In this embodiment, the temperature at the bottom of the vacuum distillation tower is 155° C., the temperature at the top of the tower is 134° C., and the vacuum degree is 2.8 torr, 6-aminocapronitrile is distilled from the top of the tower.

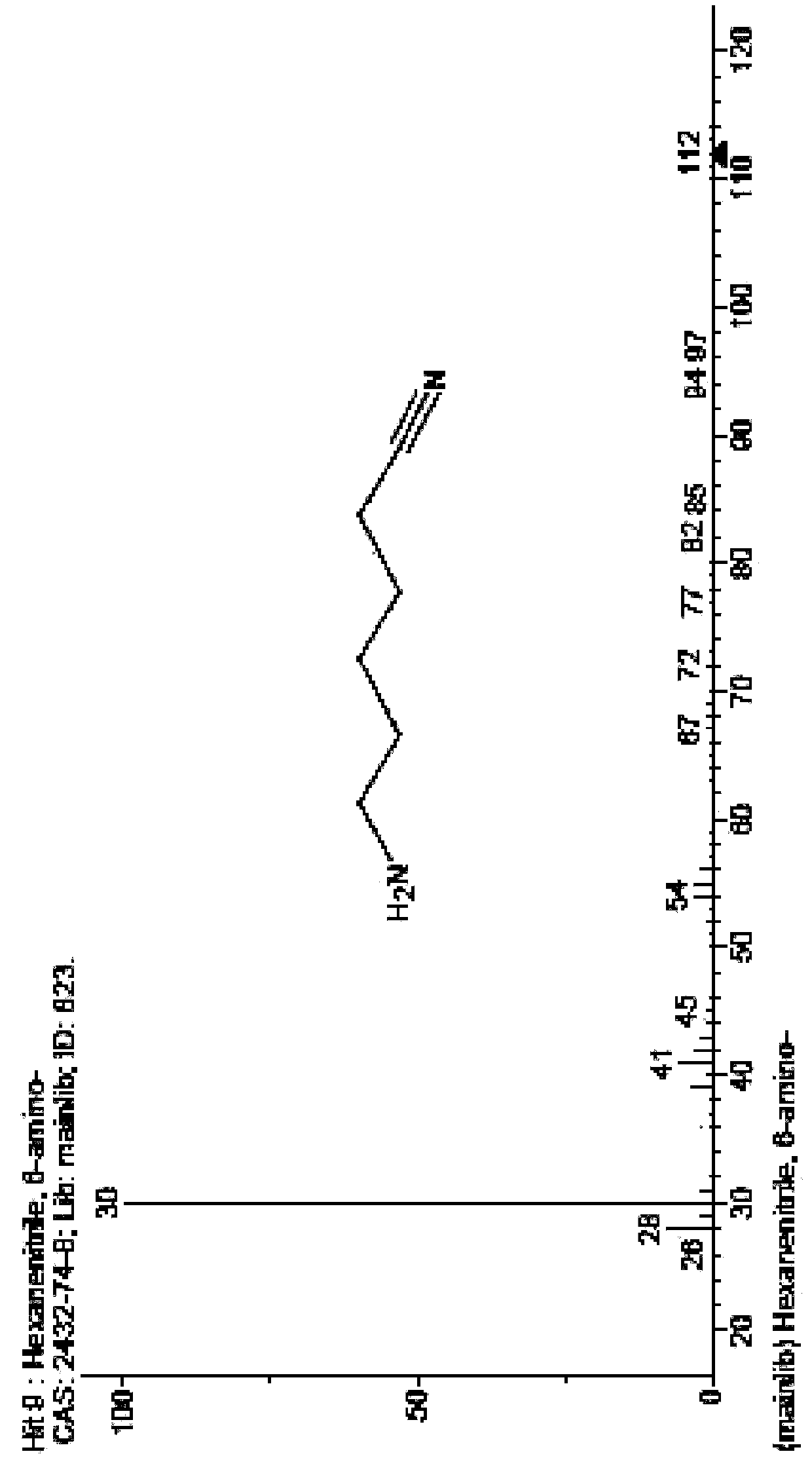

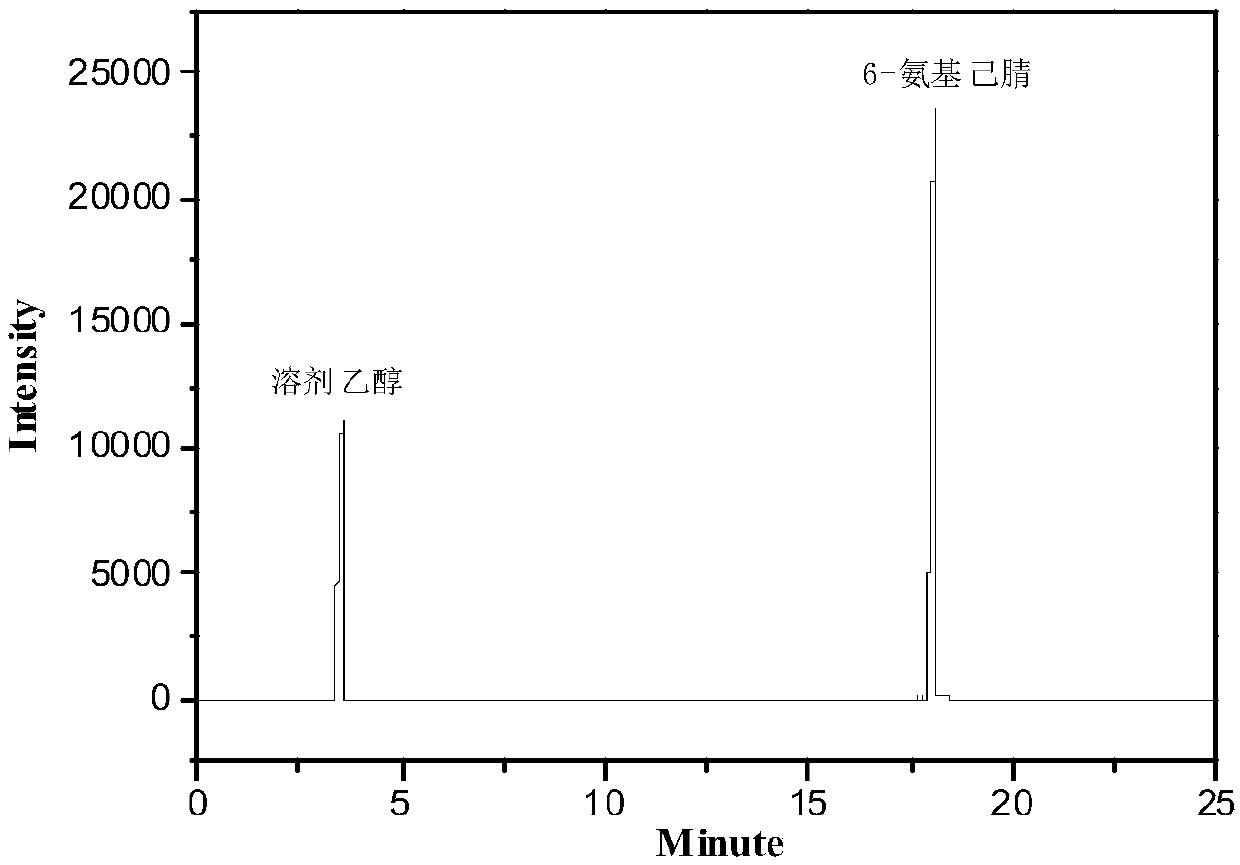

[0045] The product prepared in this embodiment is detected by gas chromatography and mass spectrometry, and the detection results are shown in figure 1 and figure 2 . Depend on figure 1 and figure 2It can be seen that the p...

Embodiment 3

[0047] Mix 10g of caprolactam, 50g of adiponitrile, and 1g of aluminum phosphate, and add them into a reaction kettle with an ammonia water separator to stir and heat at a stirring speed of 1300RPM. 2 hours. During the reaction, the mass ratio of ammonia to caprolactam was 18.2:1. After the reaction, the conversion rate of caprolactam was 56%, and the selectivity was 98.1%. The reaction product was subjected to rectification and separation to obtain 6-aminocapronitrile with a purity of 99.5%.

[0048] In this embodiment, the temperature at the bottom of the vacuum distillation tower is 158° C., the temperature at the top of the tower is 139° C., and when the vacuum degree is 3.5 torr, 6-aminocapronitrile is distilled from the top of the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com