Preparation method of water-borne long-chain acrylate separant

A technology of acrylates and release agents, applied in coatings and other directions, can solve the problems of late start of the theory of mini-emulsion polymerization, and the application field has not been fully developed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

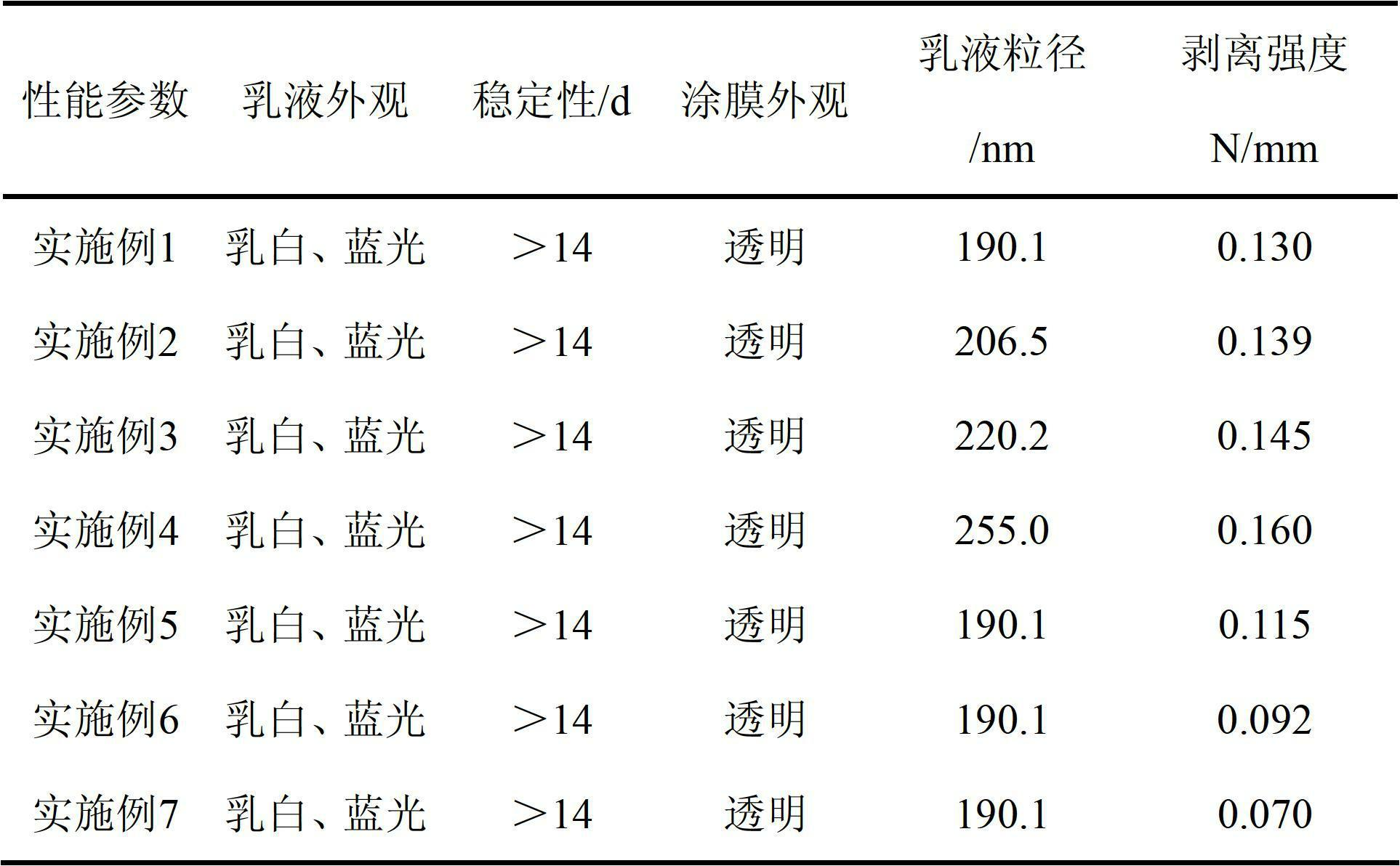

Examples

Embodiment 1

[0031] (1) Weigh raw materials according to the following weight percentages: deionized water 50%, lauryl methacrylate 9.8%, isobornyl acrylate 9.8%, methyl methacrylate 8.2%, butyl acrylate 8.2%, acrylonitrile 5.9% , acrylic acid 5.1%, sodium lauryl sulfate 1%, sodium bicarbonate 1%, ammonium persulfate 0.5%, sodium persulfate 0.5%;

[0032] (2) Add deionized water, lauryl methacrylate, isobornyl acrylate, methyl methacrylate, butyl acrylate, acrylonitrile, acrylic acid, sodium lauryl sulfate, and sodium bicarbonate into a beaker at 50°C Stir for 20min under the condition to prepare the pre-emulsion A;

[0033] (3) Place the pre-emulsion A in an ultrasonic cell pulverizer and emulsify it in an ice-water bath for 5 minutes to prepare the mini-emulsion B;

[0034] (4) Pour the above-mentioned miniemulsion B into a four-necked flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After raising the temperature to 75°C, add ammonium persulfate and sod...

Embodiment 2

[0038] (1) Weigh raw materials according to the following weight percentages: 50% deionized water, 9.8% lauryl methacrylate, 9.8% octadecyl methacrylate, 8.2% methyl methacrylate, 8.2% butyl acrylate, Styrene 5.9%, acrylic acid 5.1%, sodium dodecyl sulfonate 1%, sodium bicarbonate 1%, sodium persulfate 0.3%, ammonium persulfate 0.5%, potassium persulfate 0.4%;

[0039] (2) Add deionized water, lauryl methacrylate, octadecyl methacrylate, methyl methacrylate, butyl acrylate, styrene, acrylic acid, sodium lauryl sulfonate, carbonic acid Sodium hydrogen, stirred at 50°C for 30 minutes to prepare pre-emulsion A;

[0040] (3) Place pre-emulsion A in an ultrasonic cell pulverizer and emulsify for 5 minutes in an ice-water bath to prepare fine emulsion B;

[0041] (4) Pour the above microemulsion B into a four-neck flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After heating up to 80°C, add sodium persulfate, ammonium persulfate and potassium pers...

Embodiment 3

[0044] (1) Weigh raw materials according to the following weight percentages: 60% deionized water, 11% lauryl methacrylate, 12.5% octadecyl acrylate, 8.6% butyl acrylate, 5.9% styrene, 1.1% acrylic acid, ten Hexaalkyl sodium sulfate 0.3%, sodium bicarbonate 0.3%, ammonium persulfate 0.3%;

[0045] (2) Add in a beaker, deionized water, lauryl methacrylate, stearyl acrylate, butyl acrylate, styrene, acrylic acid, sodium cetyl sulfate, sodium bicarbonate, at 45 ° C Stir for 35min to prepare pre-emulsion A;

[0046] (3) Place the pre-emulsion A in an ultrasonic cell pulverizer and emulsify it in an ice-water bath for 5 minutes to prepare the mini-emulsion B;

[0047] (4) Pour the above-mentioned miniemulsion B into a four-necked flask equipped with a stirrer, a condenser, a nitrogen passage, and a thermometer. After heating up to 85°C, add ammonium persulfate and keep it warm for 7 hours to obtain a long-chain acrylate release agent. .

[0048] The method for testing the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com