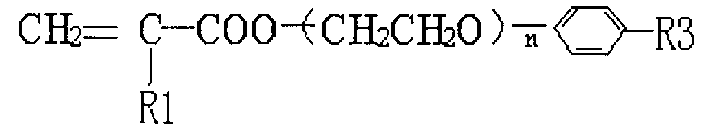

Lissapol N(methyl) propenoic acid ester and its preparation and use

A technology of alkylphenol polyoxyethylene ether methacrylate and alkylphenol polyoxyethylene ether acrylate, applied in the field of alkylphenol polyoxyethylene ether (meth)acrylate and its preparation and application, can solve the problem of No problems related to alkylphenol polyoxyethylene ether acrylate and other reports have been found, achieving the effects of less waste, high reaction conversion rate, and prevention of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

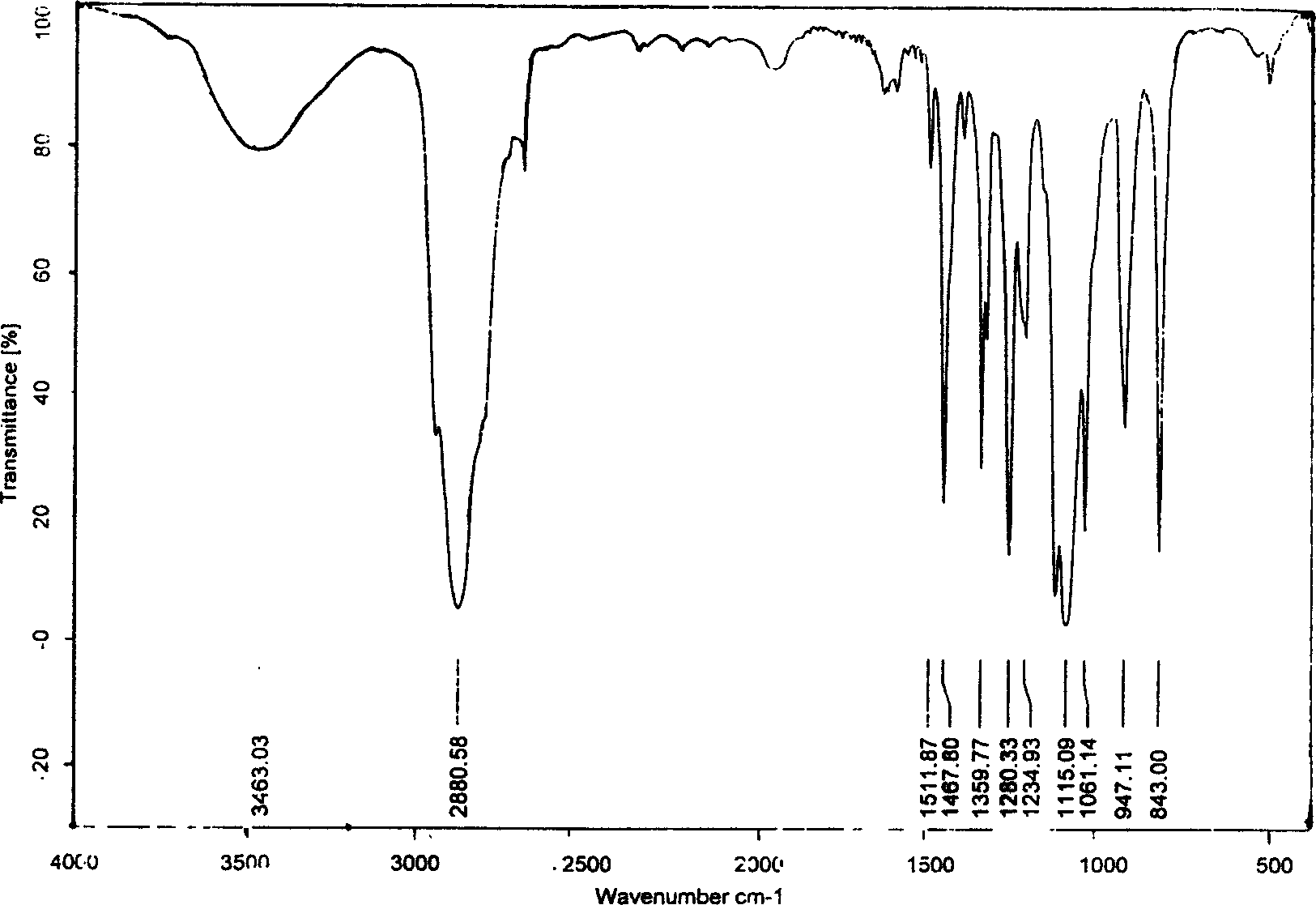

[0039] In a 500ml four-neck flask equipped with a stirring, thermometer and fractionating tower, add 80g of octylphenol polyoxyethylene ether (OP-10), 80g of methyl methacrylate, 70g of n-hexane, and 0.3g of polymerization inhibitor Z-701 , heating, start stirring, keep the temperature of the kettle at about 105°C, make the mixed reaction liquid azeotrope, separate water, until the distillate is clear and the temperature at the top of the tower reaches 68.5°C.

[0040] Then add 2.0 g of tetraethyl titanate into the reaction kettle, keep warm for reaction, take samples to analyze the methanol content in the azeotrope at the top of the tower, and stop the reaction when the methanol content in the azeotrope at the top of the tower is lower than 0.1%.

[0041] A total of 55.0 g of azeotrope was obtained in the reaction, the methanol content was 6.7% according to sampling analysis, and the conversion rate of octylphenol polyoxyethylene ether was 93.05%.

[0042] Add 20g of 10% sulf...

Embodiment 2

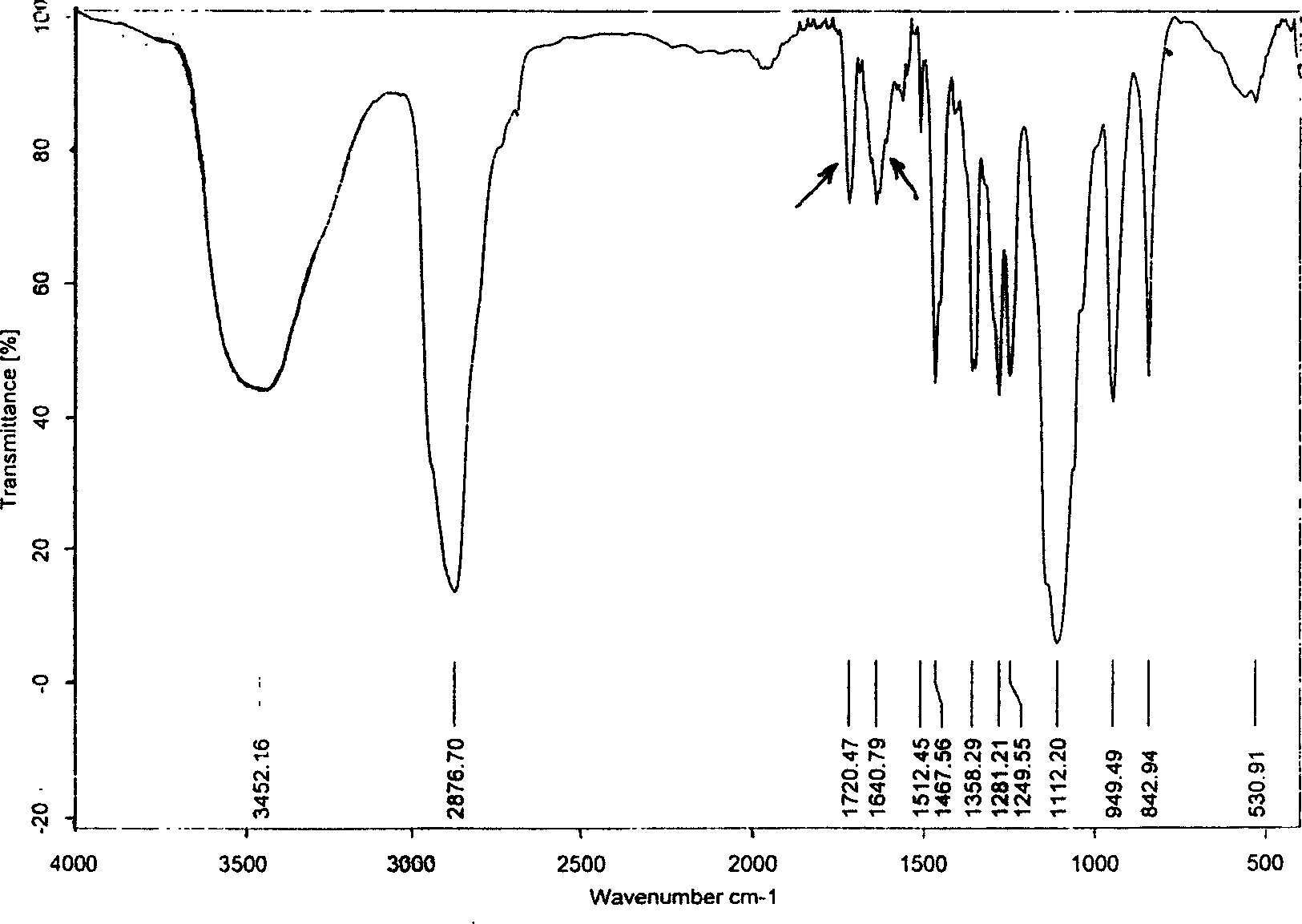

[0044] In a 500ml four-necked flask equipped with stirring, thermometer and fractionating tower, add octylphenol polyoxyethylene ether (OP-10) 80g, ethyl acrylate 80g, n-hexane 70g, polymerization inhibitor Z-701 0.3g, heat , start stirring, keep the temperature of the kettle at about 105°C, make the mixed reaction solution azeotrope, separate water, until the distillate is clear and the temperature at the top of the tower reaches 68.5°C.

[0045]Then add 2.0 g of tetrapropyl titanate into the reaction kettle, keep warm for reaction, take samples to analyze the ethanol content in the top azeotrope, and stop the reaction when the ethanol content in the top azeotrope is lower than 0.1%.

[0046] A total of 57.0 g of azeotrope was obtained in the reaction, the ethanol content of which was 9.7% according to sampling analysis, and the conversion rate of octylphenol polyoxyethylene ether was 94.55%.

[0047] Add 20g of 10% sulfuric acid to the above reaction solution, mix and stir f...

Embodiment 3

[0049] In a 500ml four-neck flask equipped with stirring, a thermometer and a fractionation tower, add octylphenol polyoxyethylene ether (OP-10) 80g, butyl acrylate 80g, toluene 80g, polymerization inhibitor Z-705 0.3g, heat, Start stirring, keep the temperature of the kettle at about 135°C, make the mixed reaction solution azeotrope, and divide the water until the distillate is clear and the temperature at the top of the tower reaches 109.5°C.

[0050] Then add 2.0 g of tetraethyl titanate into the reaction kettle, keep warm for reaction, take samples to analyze the butanol content in the top azeotrope, and stop the reaction when the butanol content in the top azeotrope is lower than 0.1%.

[0051] A total of 63.0 g of azeotrope was obtained in the reaction, the content of butanol was 13.7% according to sampling analysis, and the conversion rate of octylphenol polyoxyethylene ether was 94.22%.

[0052] Add 20g of 10% sulfuric acid to the above reaction solution, mix and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com