Conductive polymer composition, solid electrolyte and solid electrolyte capacitor using the conductive polymer

A conductive polymer, solid electrolyte layer technology, used in capacitor electrolytes/absorbers, capacitor parts, non-metallic conductors, etc., can solve problems such as low performance, achieve excellent stability, excellent electrical capacity performance, high conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

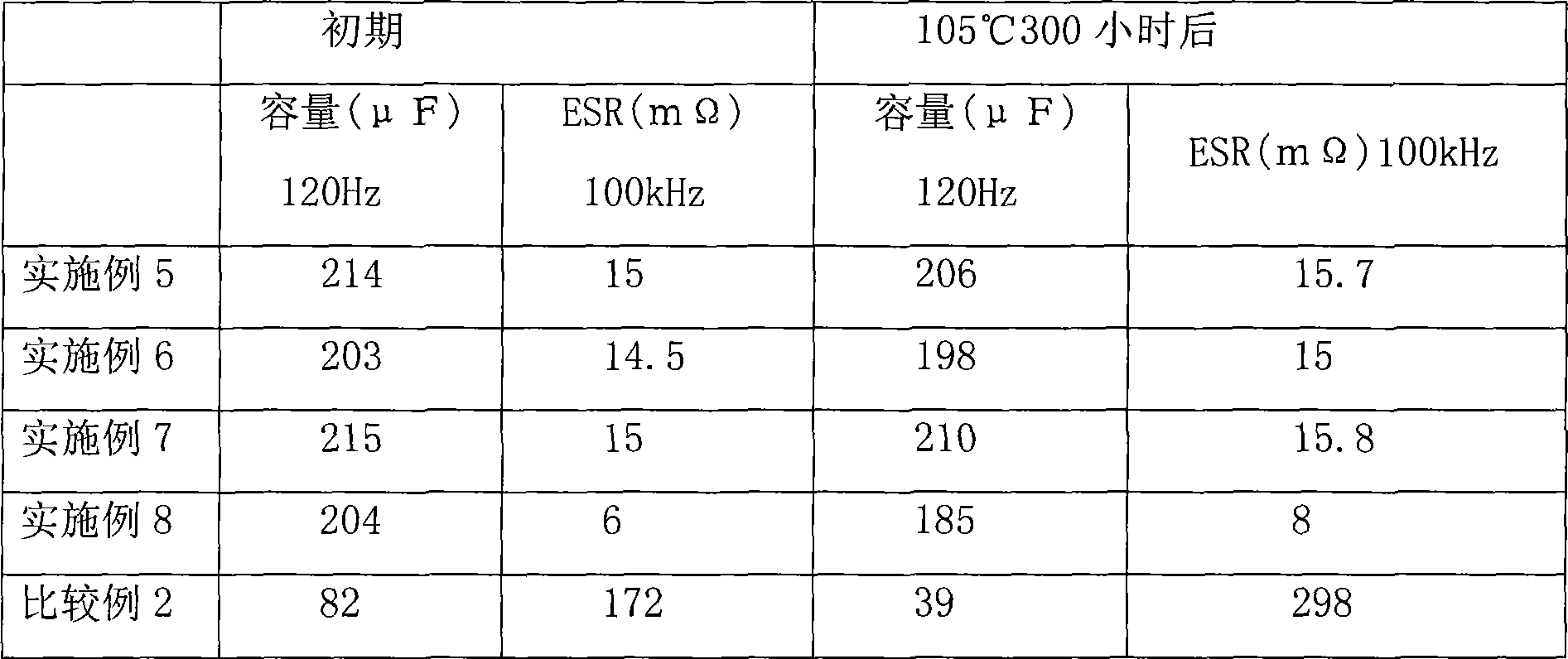

Examples

Embodiment 1

[0086] With 10g of 3,4-ethylenedioxythiophene (EDOT), 80g of 30wt% polystyrene sulfonic acid aqueous solution (average molecular weight 75,000) and 20g of sodium persulfate, 2g of iron sulfate (III) dissolved in 1500ml water, stirred for 18 hours.

[0087] Ion exchange resin was used to remove residual ions in the solution to obtain dark blue 1.5 wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene (PSS / PEDOT) aqueous solution.

[0088] The obtained 10g of 1.5wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene aqueous solution and 0.45g of polyethylene glycol 200 acrylate were mixed and stirred, and dried in an oven at 120°C , to obtain a conductive coating. Table 1 shows the results of evaluating the electrical conductivity of the conductive coating film.

Embodiment 2

[0090] With the 1.5wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy) thiophene aqueous solution prepared by Example 1, 0.3g of dipropylene glycol acrylate, 0.5g of dimethyl sulfoxide mixed and stirred Afterwards, it was dried in an oven at 120° C. to obtain a conductive coating film. Table 1 shows the results of evaluating the electrical conductivity of the conductive coating film.

Embodiment 3

[0092] With the 1.5wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy) thiophene aqueous solution of the 10g preparation of embodiment 1, the diethylene glycol diacrylate of 0.30g, the dihydroxybenzene of 0.15g mix After stirring, it was dried in an oven at 120° C. to obtain a conductive coating film. Table 1 shows the results of evaluating the electrical conductivity of the conductive coating film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com