Production of aluminium by low-temperature electrolytic process and special aluminium electrolytic tank thereof

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of non-ferrous metal materials, can solve the problems of low dissolution rate and low alumina solubility, achieve high solubility and dissolution rate, overcome low-temperature aluminum electrolysis, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

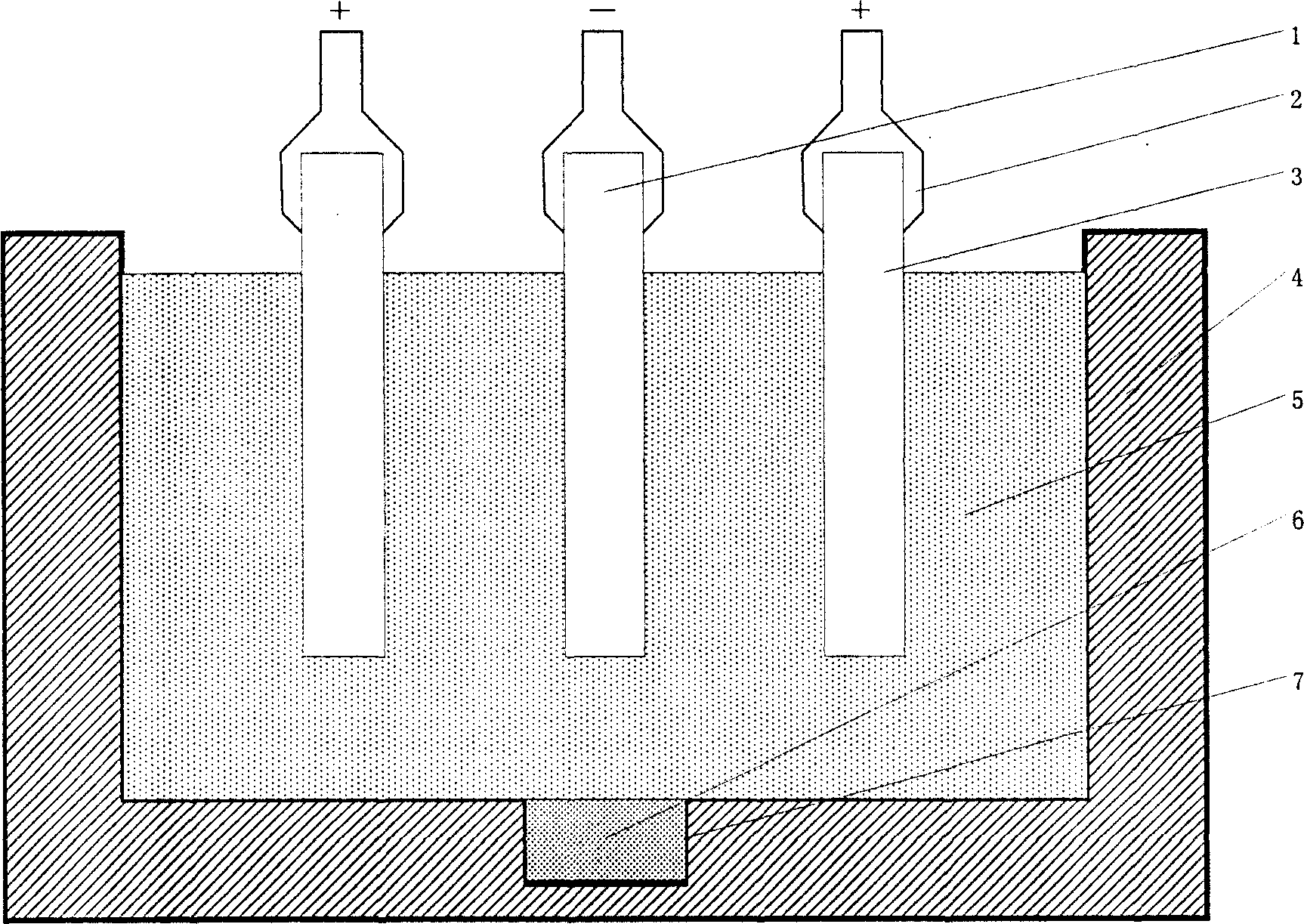

[0010] Example 1, the current intensity of the aluminum electrolytic cell is 180kA, and the material used for the cathode is TiB 2 and MoSi 2 Composite material, MoSi 2 8% by weight, TiB 2 The weight percent content is 92%, and it is made by powder metallurgy forming method. The material used for the anode is metal inert material, the composition is Sn, Cu, Ni, Fe, and the weight percentage content is 20%, 60%, 10%, 10% respectively. It is made by powder metallurgy method. Both the cathode and the anode are made into flat plates. The electrodes in the cell are vertically arranged in the form of Yang-Yin-Yang-Yin·-Yang, the surfaces of the electrodes are parallel to each other, and the pole distance of the electrolytic cell is 2.5cm. Both the electrolytic cell material and the aluminum sink material use silicon nitride combined with silicon carbide materials. The electrolyte used in the electrolysis is a potassium cryolite molten salt system, wherein the potassium cryolite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com