Conductive printing ink composite for printing of wireless radio frequency identification devices (RFID)

A conductive ink and identification system technology, applied in ink, applications, household appliances, etc., can solve the problems of low conductivity and low bonding strength, and achieve the effects of high conductivity, stable electrical properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

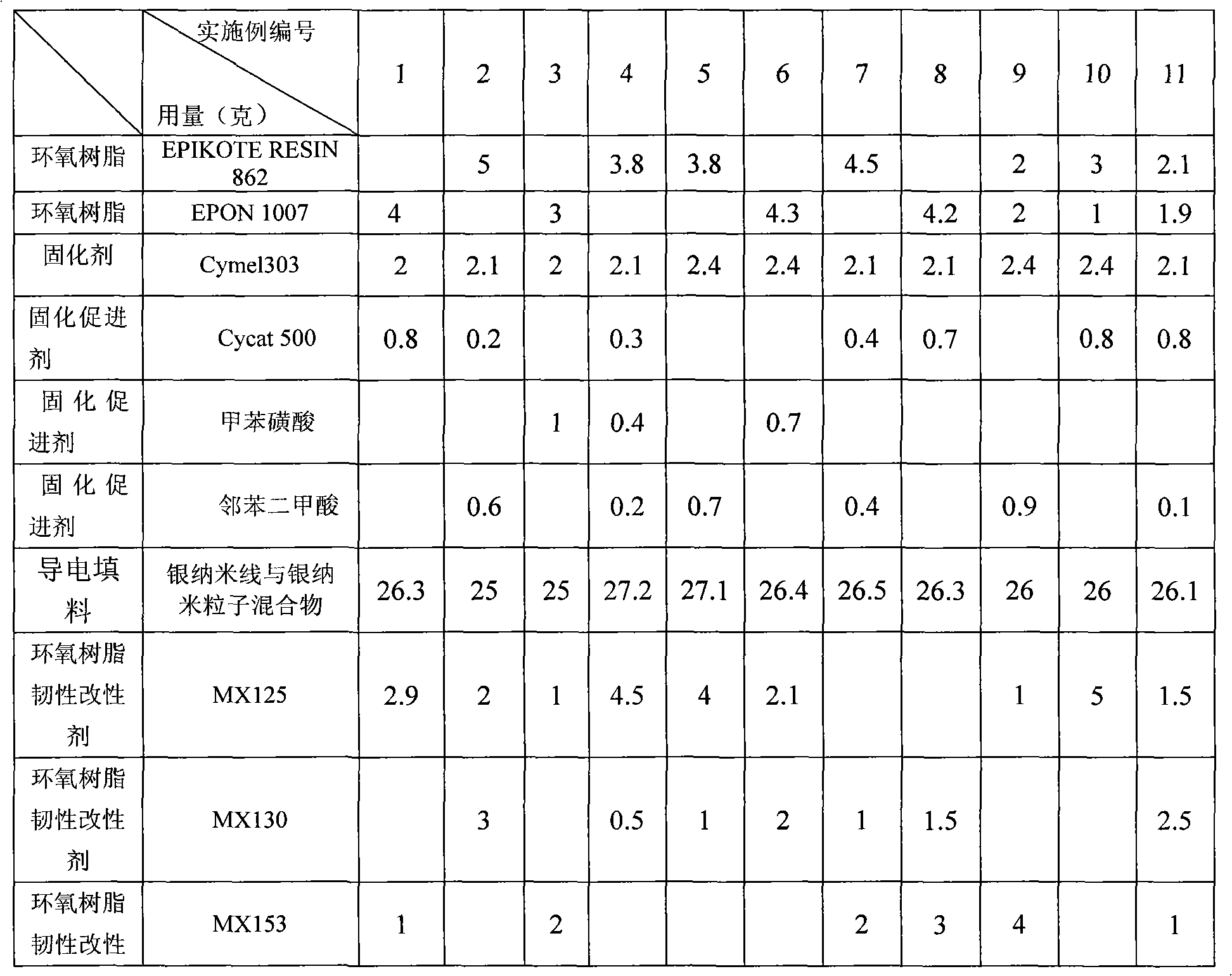

[0029] Example 1: Weigh the epoxy resin, epoxy toughness modifier, adhesion promoter, rheology control agent according to the mass given in Table 2 and mix them. The mixing method is mechanical stirring, the stirring speed is 1000 rpm, and the time is 10 minutes. Then, the weighed mixed filler of silver nanowire and silver nanoparticle, filler surface modifier, and diluent are sequentially added to the mixture under stirring. After the addition, stirring was continued for 10 minutes. After mixing uniformly, add curing agent and curing accelerator to the mixture. After mechanical stirring for 5 minutes, transfer the mixture to a high-speed shear mixer for mixing. The mixing speed is 2000 rpm and the time is 30 seconds. Repeat the mixing process in the high-speed shear mixer 3 times to obtain a uniformly mixed gel that is the conductive ink.

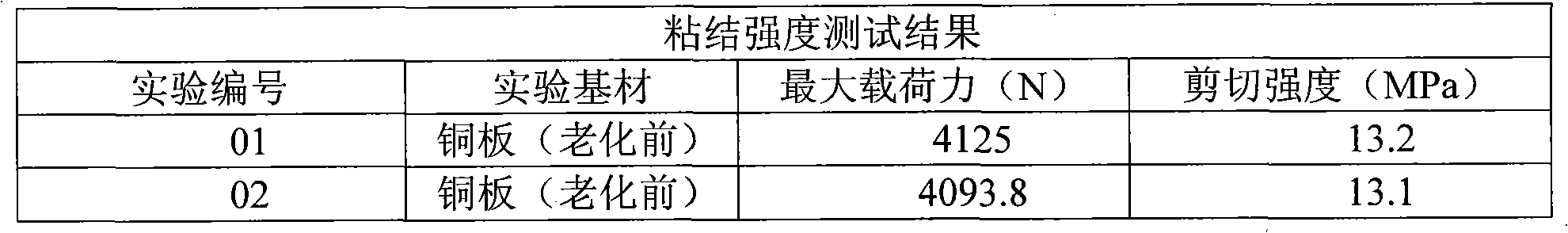

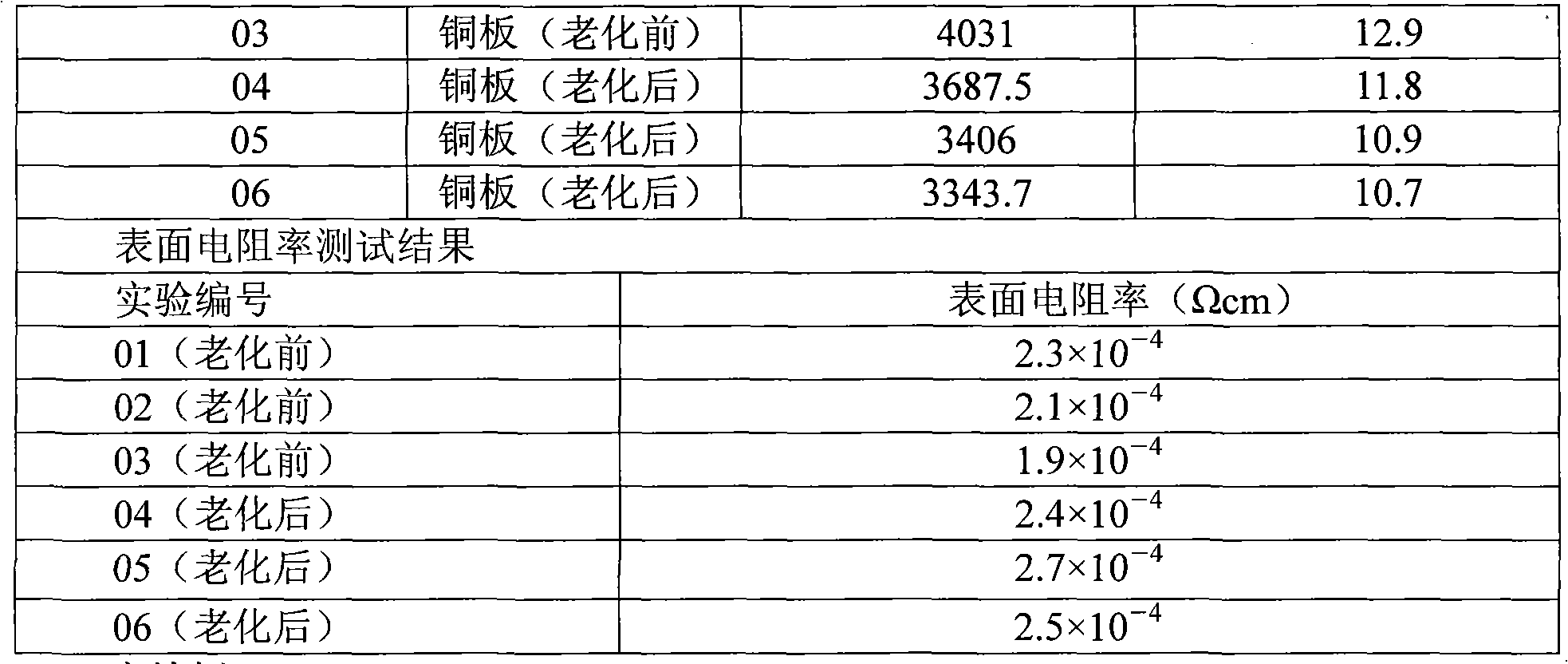

[0030] The preparation of the test sample for the bonding strength of the conductive ink is carried out in accordance with the standard AS...

Example

[0034] Examples 2-11

[0035] According to the ingredients and dosage listed in Table 2, weigh the epoxy resin, epoxy toughness modifier, adhesion promoter, rheology control agent, etc. and mix them. The mixing method is mechanical stirring, the stirring speed is 1000 rpm, and the time is 10 minutes. Then, the weighed conductive filler, filler surface modifier, and diluent are sequentially added to the mixture under stirring. After the addition, stirring was continued for 10 minutes. After the mixing is uniform, the curing agent and curing accelerator are added to the mixture, and the mixture is transferred to a high-speed shear mixer for mixing after mechanical stirring for 5 minutes. The mixing rate is 2000 rpm and the time is 30 seconds. Repeat the mixing process in the high-speed shear mixer 3 times to obtain a uniformly mixed jelly that is the conductive ink composition.

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com