Square filtering tank for beer saccharification filtering system

A filtration system and beer sugar technology, which is applied in the field of special filtration systems for beer saccharification, can solve the problems of different frictional forces and affect the quality of wort filtration, and achieve the effect of improving beer quality and wort filtration quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

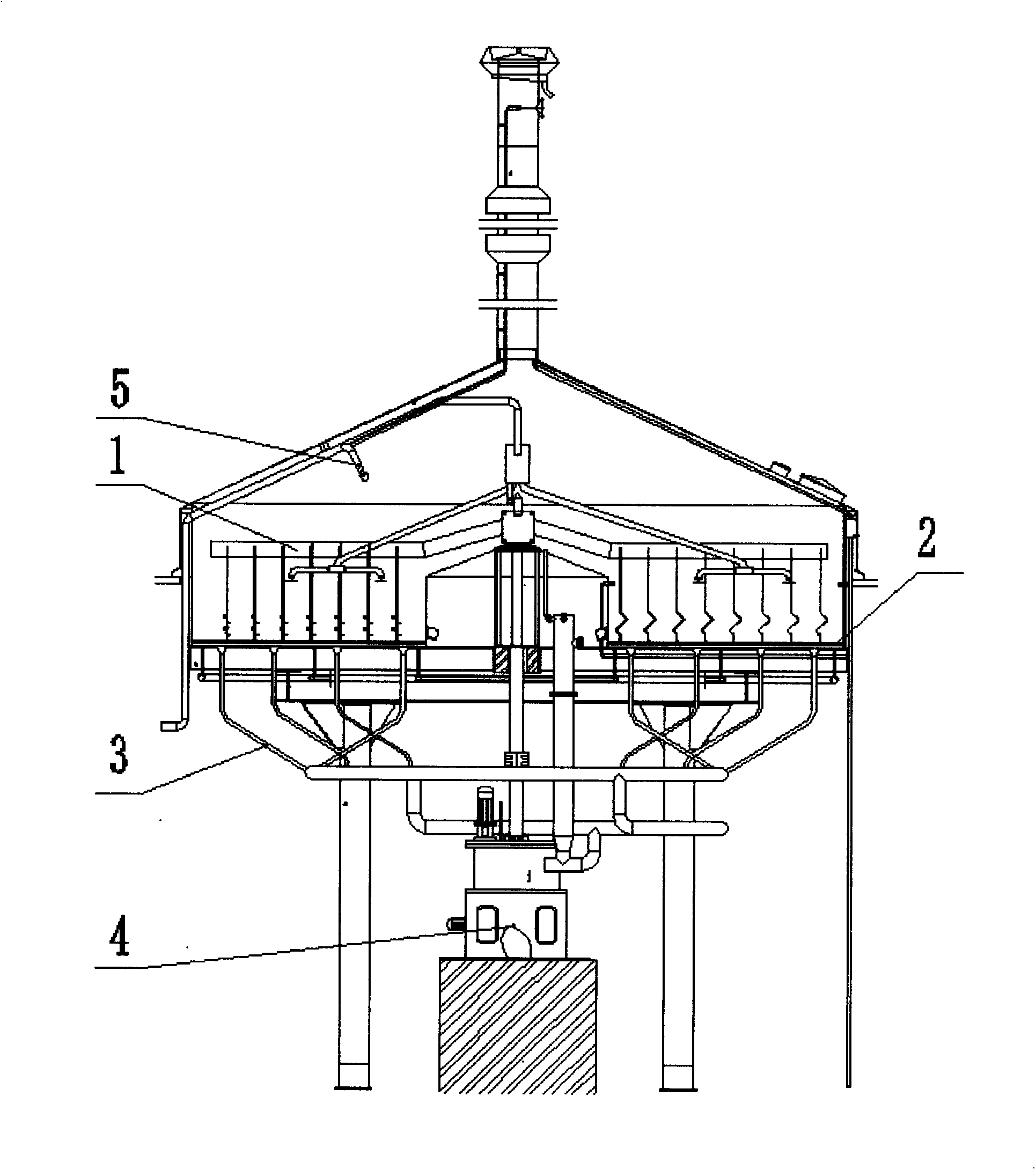

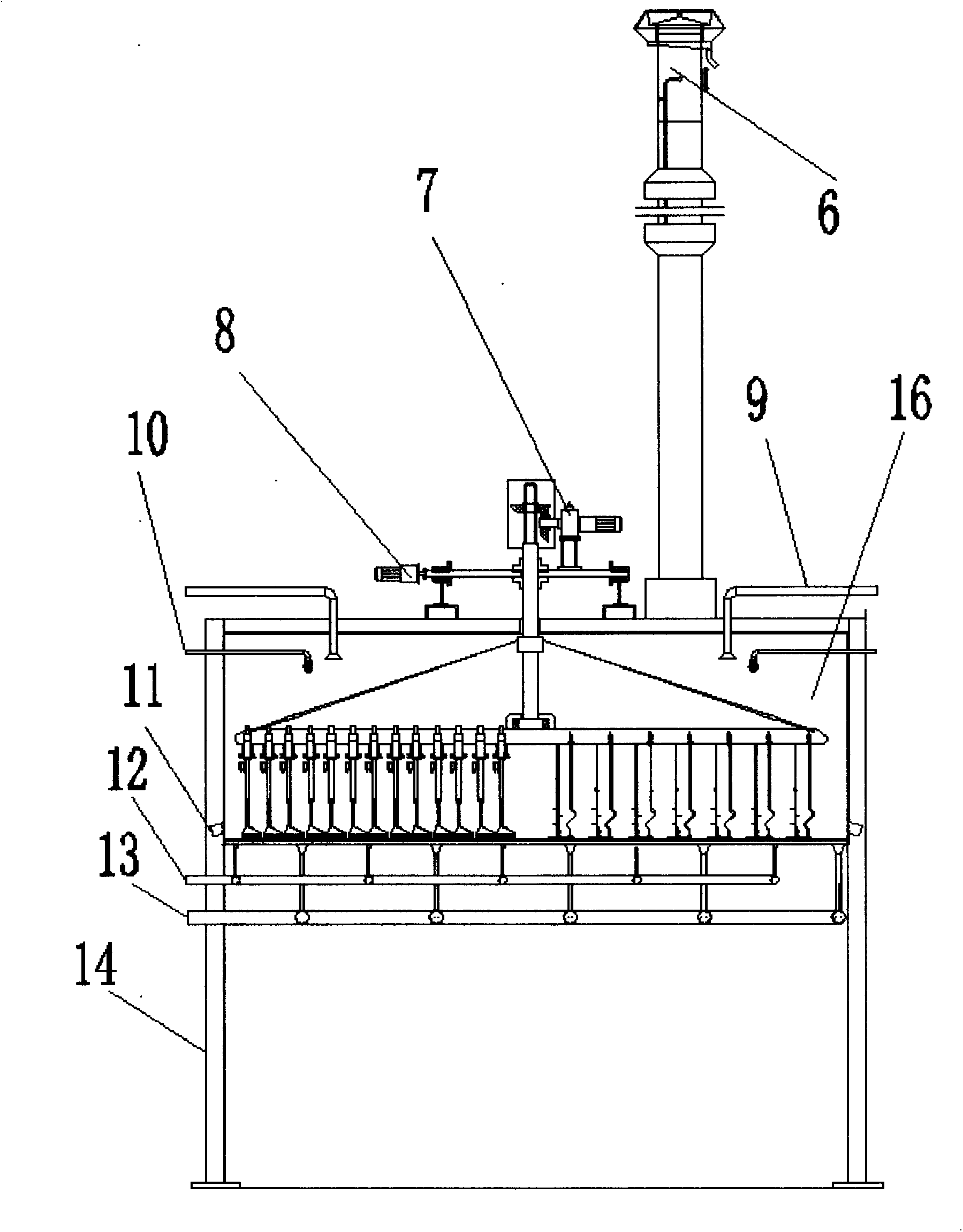

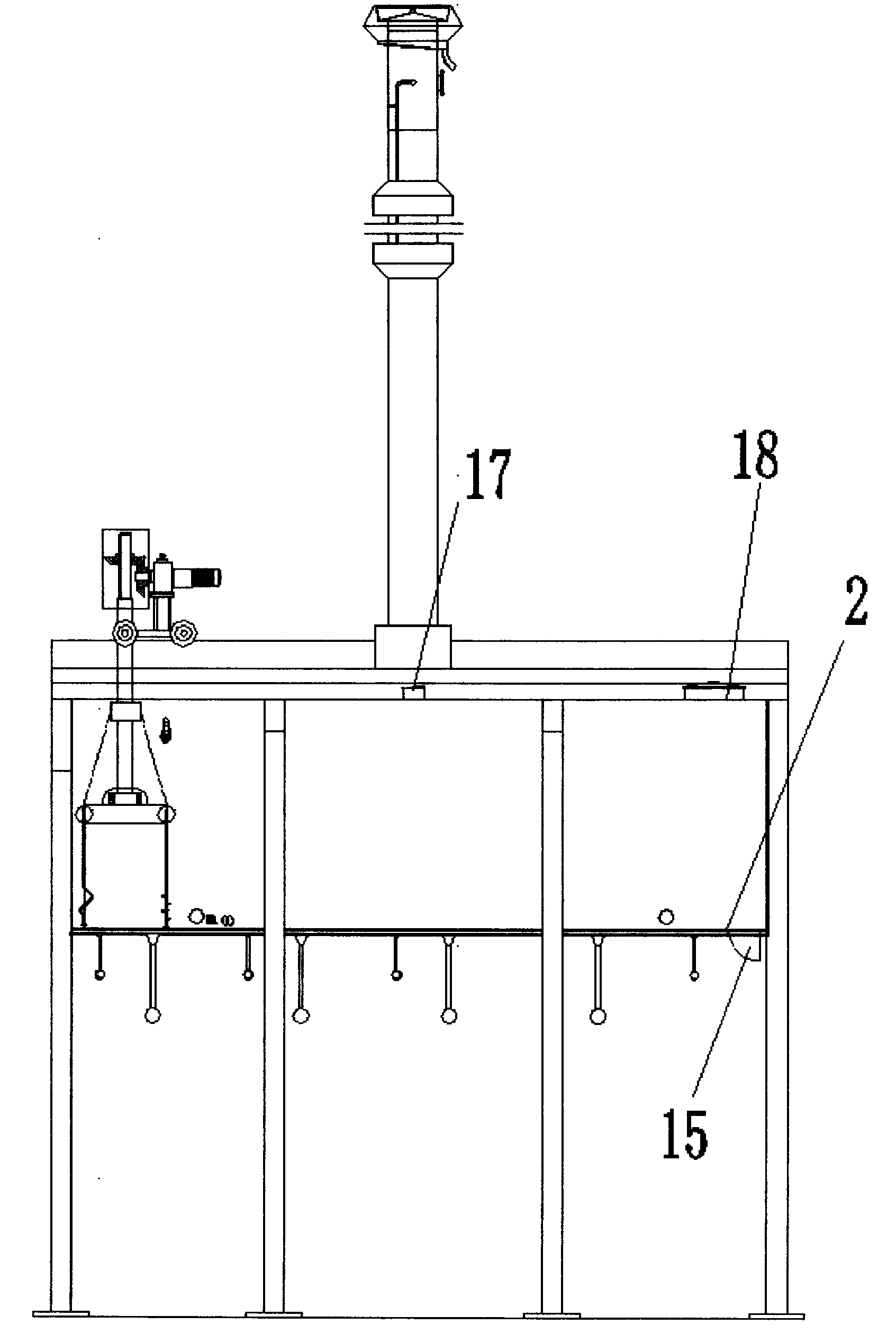

[0015] refer to figure 1 , the specific embodiment adopts the following technical solutions: a square filter tank for the beer saccharification filtration system, including a filter plate 2, an exhaust cylinder 6, a trough lifting device 7, a tillage tank reciprocating device 8, a washing tank water inlet 9, and a washing water inlet 10. Outrigger 11, mash inlet 12, backwash water inlet 13, wort outlet 14 and groove door 15, the tank body 16 is fixed on the ground by the outrigger 11, and the top of the tank body 16 is fixed with an exhaust cylinder 6 The groove body 16 is slidably provided with a trough elevating device 7 and a tillage trough reciprocating device 8, the trough elevating device 7 and the tillage trough reciprocating device 8 are all connected with the big arm of the trough in the trough body 16, and the trough body 16 is also provided with There is a washing tank water inlet 9, a washing water inlet 10 is arranged on the side of the tank body 16, a mash inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com