Straw returning machine for different crops

A crop and straw technology, applied in the field of straw returning machine, can solve the problem of time-consuming and labor-intensive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

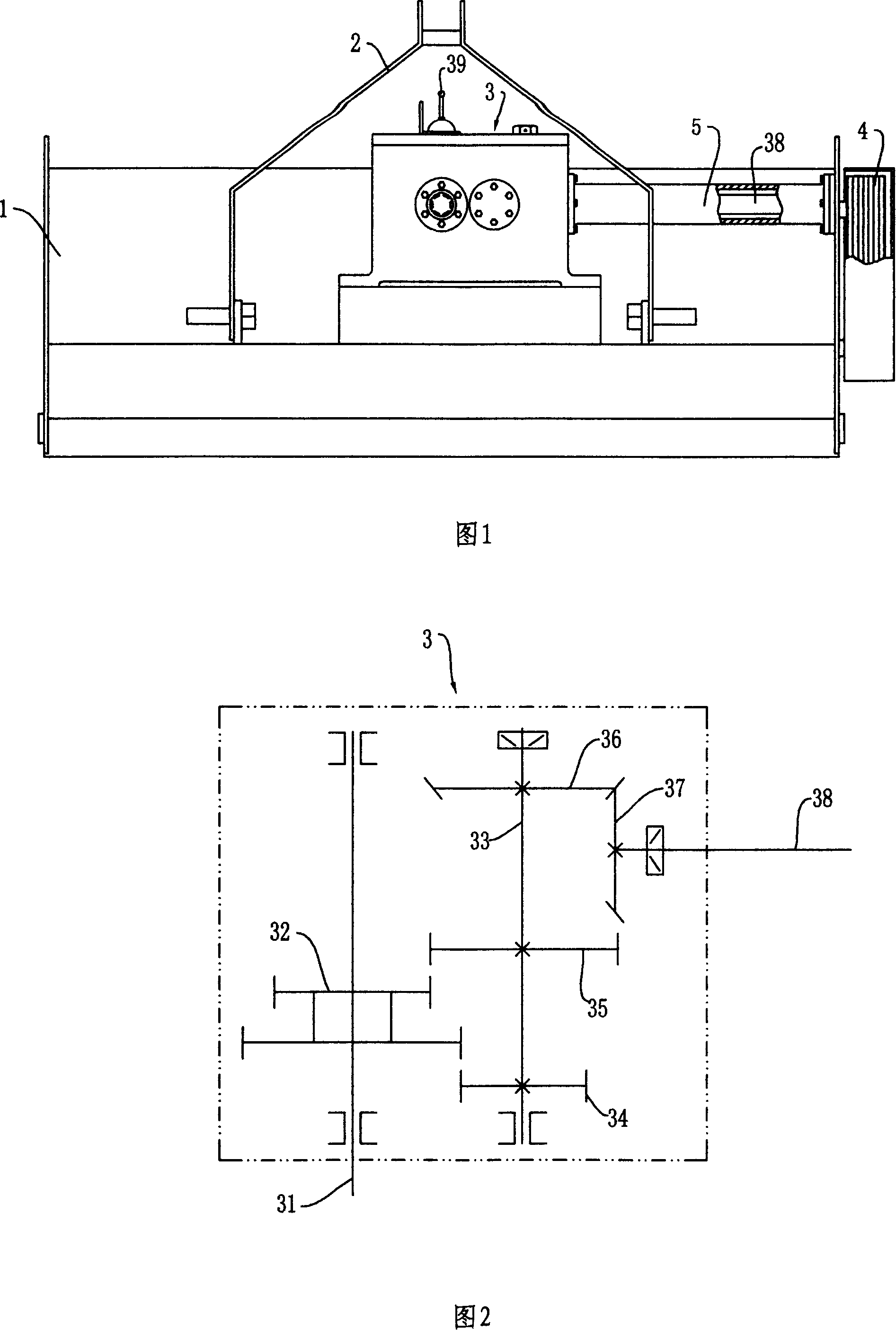

[0010] A straw returning machine for different crops, as shown in Figure 1, includes a frame 1 with a connecting frame 2, a first transmission device 3 is installed on the upper part of the frame 1 and is located in the middle of the frame 1 , the first transmission device 3 is composed of a gear box that can transmit power vertically. The second transmission device 4 is installed on the side of the frame 1, and is used to directly drive the pulverizer roller to rotate; the second transmission device 4 is composed of a belt transmission device.

[0011] As shown in Figure 2, the gear box includes a box input shaft 31 that can be connected with the rear output shaft of the tractor, a box intermediate shaft 33, and a box output shaft that can be connected with the input shaft of the second power unit 4. Shaft; and the double slip gear 32 installed on the gearbox input shaft 31, fixedly connected to the first spur gear 34, the second spur gear 35 and the first bevel gear 36 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com