Composite nanometer photocatalyst electrospun fiber filtering material and preparation method thereof

A nano-photocatalyst and electrospun fiber technology, applied in the field of fiber filter materials, can solve the problems of excessive fiber size and pore size diameter, and difficulty in controlling the bulk density, and achieve improved filtration quality, improved penetration rate and pressure loss, and low The effect of penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

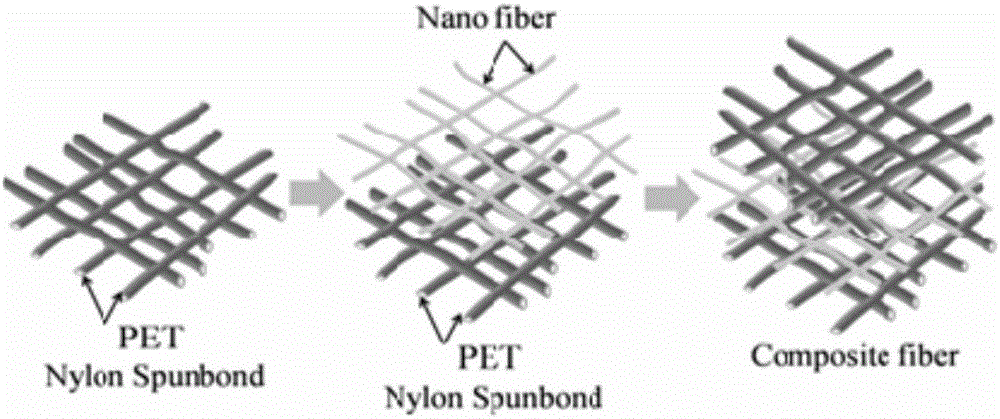

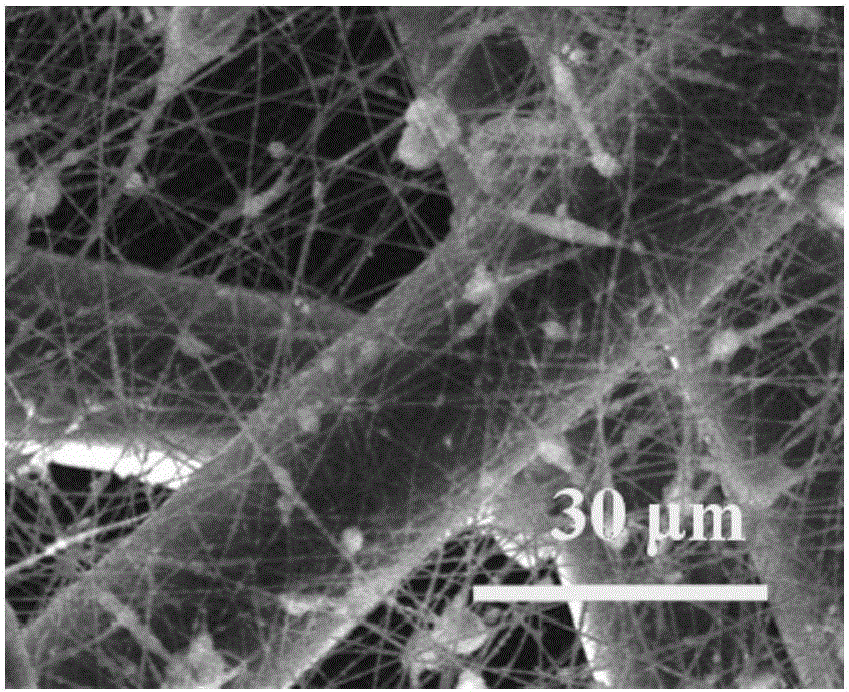

[0027] The composite nanometer photocatalyst electrospun fiber filter material is provided with a carrier, and a layer of photocatalyst fiber is coated on the carrier.

[0028] The carrier can adopt micron polyethylene terephthalate fiber.

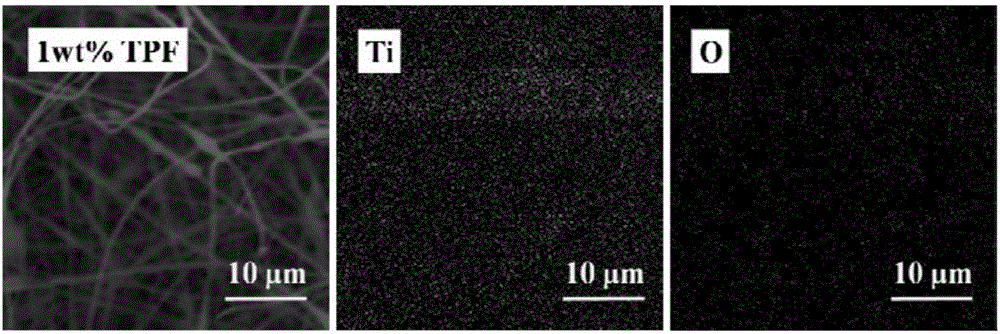

[0029] The photocatalyst fiber refers to a mixed polymer solution formed by dissolving polyacrylonitrile and titanium dioxide in dimethylacetamide, and then prepared through an electrospinning device.

[0030] The preparation method of described composite nano photocatalyst electrospun fiber filter material, comprises the following steps:

[0031] 1) Mixing polyacrylonitrile and dimethylacetamide and heating to obtain a polymer solution; the heating temperature may be 70-80°C, and the heating time may be 6-7h; the obtained polymer solution The mass percent concentration can be 6%. The preferred heating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com