Cleaning system

A technology of cleaning system and cleaning roller, applied in the field of cleaning system, which can solve the problems of inability to remove foreign matter, poor maintainability, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 specific Embodiment approach

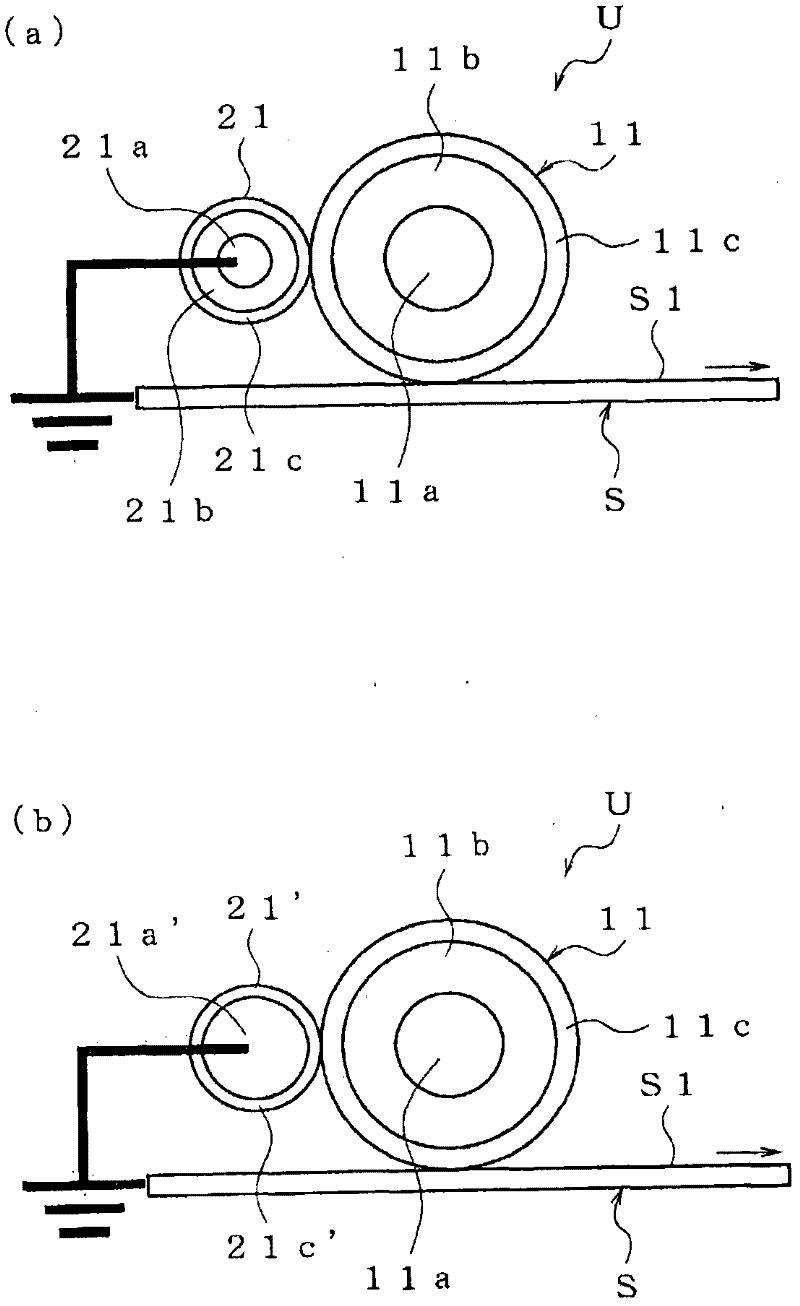

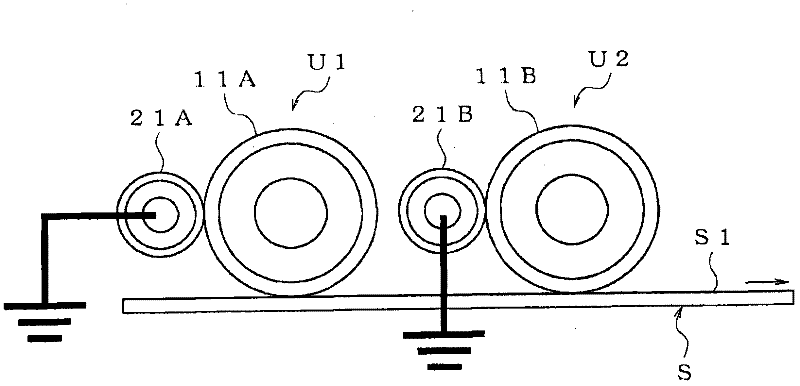

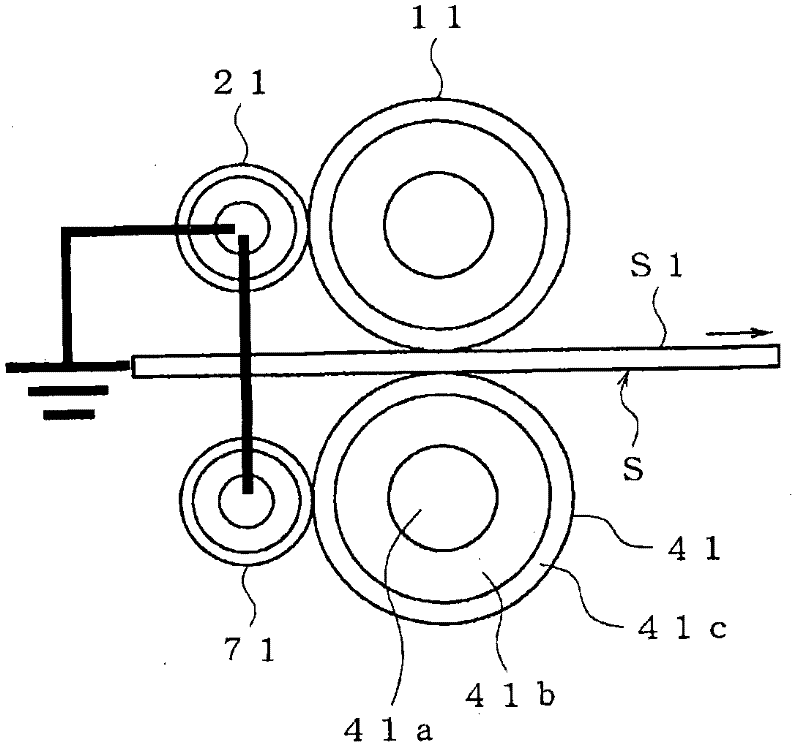

[0167] Such as Figure 12 As shown in (a), the cleaning unit U used in the cleaning system according to the present invention moves the material S to be cleaned relatively while rotating on the surface S1 of the material S to be cleaned while contacting the surface of the cleaning roller 111, and by means of The cleaning roller 111 removes foreign matter such as dust adhering to the surface S1 of the material S to be cleaned by electrostatic force (conductors or dielectrics are not shown).

[0168] The cleaning roller 111 can be charged on the surface by electrostatic force to absorb the charge of foreign matter adhering to the surface S1 of the material S to be cleaned, and use the chargeability of the roller surface (outer peripheral surface) of the cleaning roller 111 to absorb foreign matter. The cleaning roller 111 is rotatably held by an insulating member (not shown), and an electrification control that rotates while contacting the surface (outer peripheral surface) of t...

no. 2 specific Embodiment approach

[0253] Such as Figure 21 As shown in (a), in the cleaning unit U used in the cleaning system, on the surface S1 of the material S to be cleaned, it contacts the surface (peripheral surface) of the cleaning roller 211 and rotates while relatively moving, and by means of the cleaning roller 211 Foreign matter such as dust adhering to the surface S1 of the material S to be cleaned is removed by electrostatic force (conductors or dielectrics are not shown).

[0254] This cleaning roller 211 can peel off the charge for foreign matter attached to the surface S1 of the material S to be cleaned by electrostatic force to remove the charge on the surface by contact with the material S to be cleaned, and is equipped with: a conductive mandrel (mandrel) 211a; a cylindrical inner layer part 211b arranged outside the mandrel 211a; a thin cylindrical outer layer part 211c (for example, a thickness of 30 μm) made of a material with higher resistance than the inner layer part 211b arranged ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com