Filter with fiber filter element rotary displacement

A rotary displacement and filter technology, applied in the direction of loose filter material filter, gravity filter, filtration and separation, etc., can solve the problem that the fiber bundle cannot be compacted and stretched loosely, and the fiber porosity cannot be adjusted. High-precision water quality, filtration Large resistance and other problems, to achieve the effect of long filtration cycle, simple structure and high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

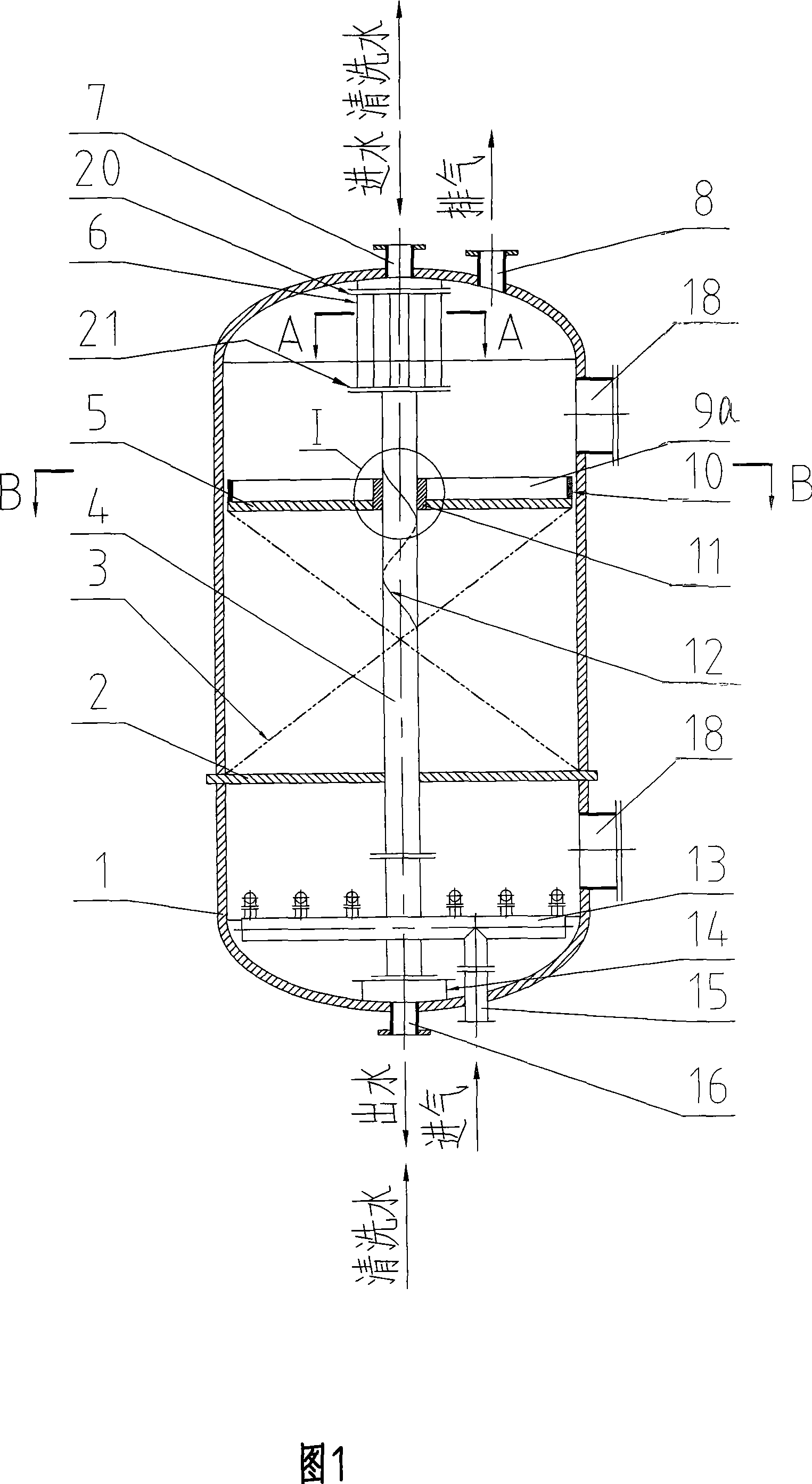

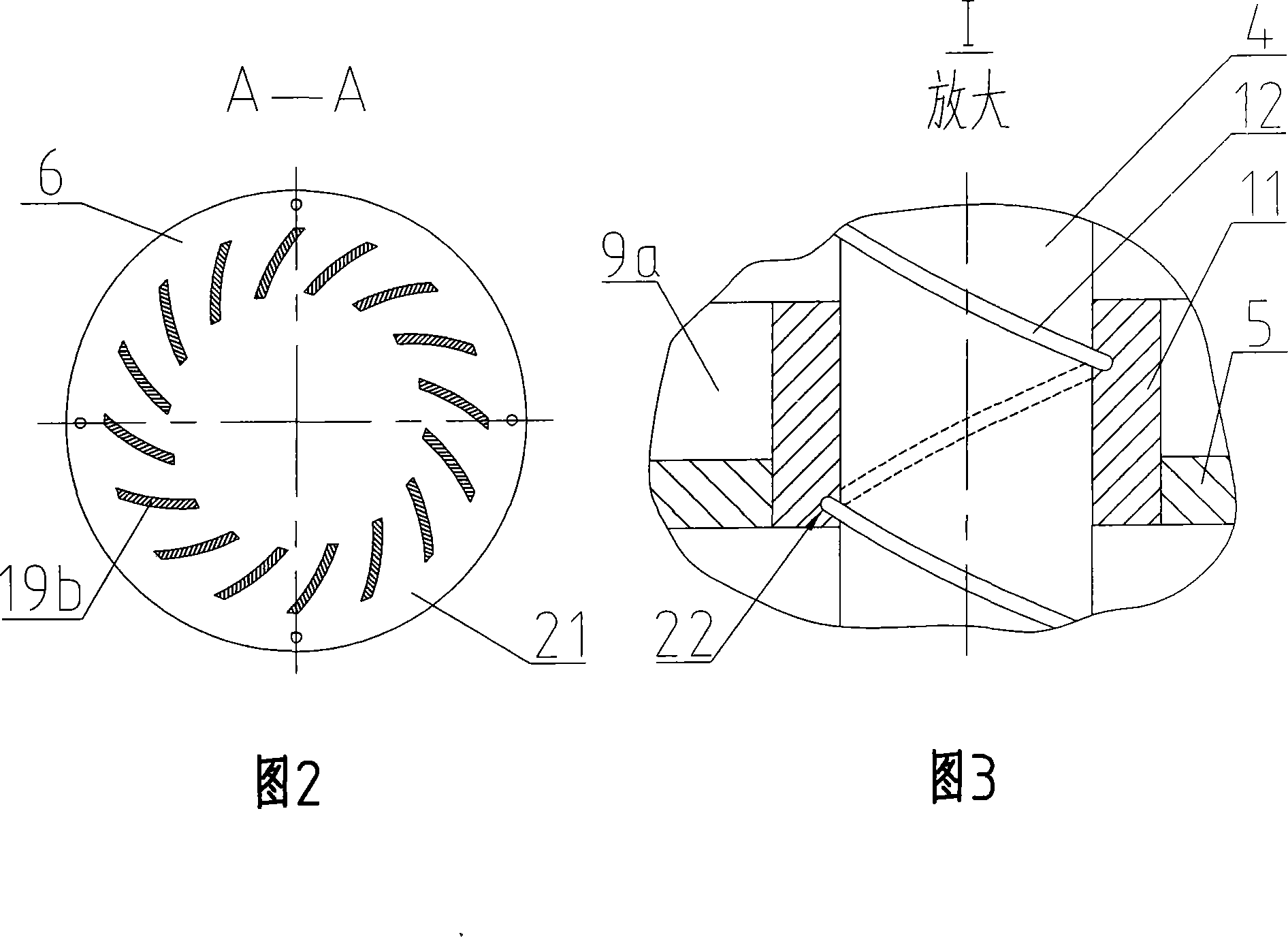

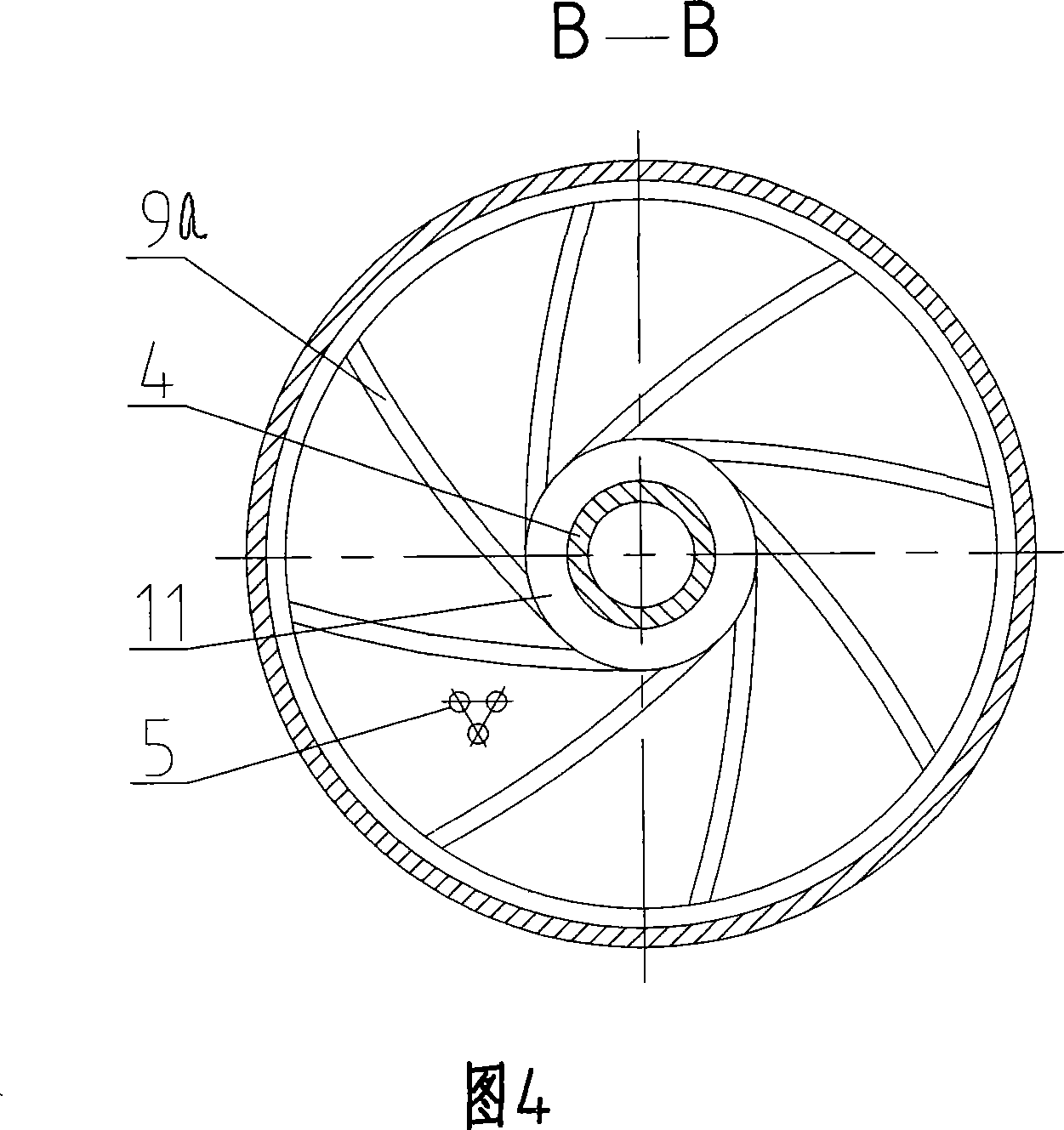

[0015] Embodiment 1: Referring to Figures 1 to 4, the fiber filter element in this embodiment can rotate and displace the filter as a downward flow filter structure. It has a tank body 1, and the tank body 1 is composed of upper and lower heads and a middle tank body after welding. A water inlet 7 and an exhaust port 8 are arranged on the upper head of the tank body 1 , and a water outlet 16 and an air inlet 15 are arranged on the lower head of the tank body 1 . A manhole 18 is provided on the tank body 1 . A water distribution device 6 and a water outlet device 14 communicated with the water inlet 7 and the water outlet 16 are respectively provided. The bottom in the tank body 1 is provided with a gas distribution device 13 communicating with the air inlet 15, the lower end in the tank body 1 is provided with a fixed orifice 2, and the upper end in the tank body 1 is provided with a movable orifice 5. A fiber filter element 3 is arranged between the fixed orifice plate 2 an...

Embodiment 2

[0017] Embodiment 2: Referring to FIG. 5 , the fiber filter element in this embodiment can rotate and displace the filter as an upward flow filter structure. Its basic structure and working principle are the same as those of Embodiment 1, the only difference is that the water outlet 16 (ie: cleaning water inlet) is set on the upper head of the housing 1, and the water inlet 9 (ie: cleaning water outlet) is set On the lower head of the housing 1 , the fixed orifice plate 2 is arranged at the inner upper end of the housing 1 , and the floating orifice plate 6 is arranged at the inner lower end of the housing 1 .

Embodiment 3

[0018] Embodiment 3: Referring to FIG. 6 , the fiber filter element in this embodiment can rotate and displace the filter as a downward flow filter structure. The tank body 1 is composed of two sections of cylindrical tank bodies and a section of conical tank body 17 with a fiber filter element 3 fixedly connected in the middle. The diameter of the conical tank body 17 is from large to small; Make a cone. This structure of the tank body 1 is more conducive to the realization of deep filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com