Sump oil vibration filtering device

A technology of vibrating filtration and vibrating filter plates, which is applied in the direction of mobile filter element filters, filter separation, separation methods, etc., can solve the problems of plate filter cleaning, inconvenient replacement of filter elements, poor filtering effect, and slow filtering speed. Achieve the effects of reducing labor intensity, improving quality, and increasing filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

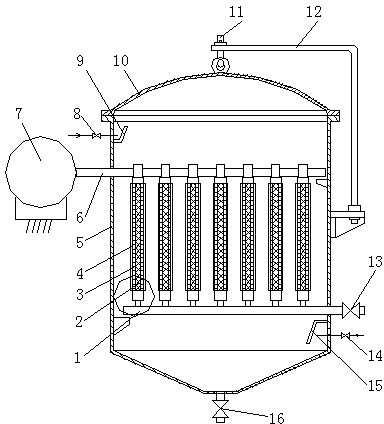

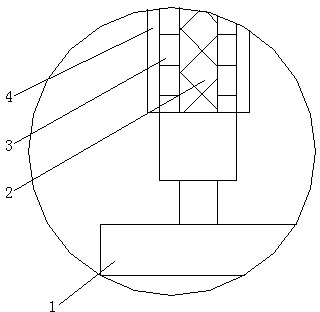

[0015] refer to figure 1 , figure 2 , a dirty oil vibrating filter device, a vibrating filter plate is longitudinally arranged in the tank body 5, an oil outlet pipe 1 is connected to the bottom of the vibrating filter plate, and one end of the oil outlet pipe 1 extends out of the tank body 5 and is provided with an oil discharge valve 13. A vibrating shaft 6 is connected to the top of the vibrating filter plate, an air inlet pipe and an air inlet valve 8 are arranged on the upper part of the tank body 5, an oil inlet pipe and an oil inlet valve 14 are arranged on the lower part of the tank body 5, and an oil inlet pipe and an oil inlet valve 14 are arranged on the upper part of the tank body 5. The bottom of the tank is provided with a sewage pipe and a sewage valve 16, and the vibration shaft 6 is connected to the vibration pump 7 outside the tank body 5. The inner layer of the vibration filter plate is the filter core 2 and the supporting frame, and the outer layer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com