Technique for preparing returnable bottle piece spinning hollow fiber

A production process and technology for recycling bottles, applied in fiber processing, textiles and papermaking, single-component polyester rayon, etc., can solve the problems of single structure and shape, high impurity content in recycled bottle flakes, poor hand feeling, etc. To achieve the effect of capillary effect and high air permeability, ensure normal and stable operation, and improve filtration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

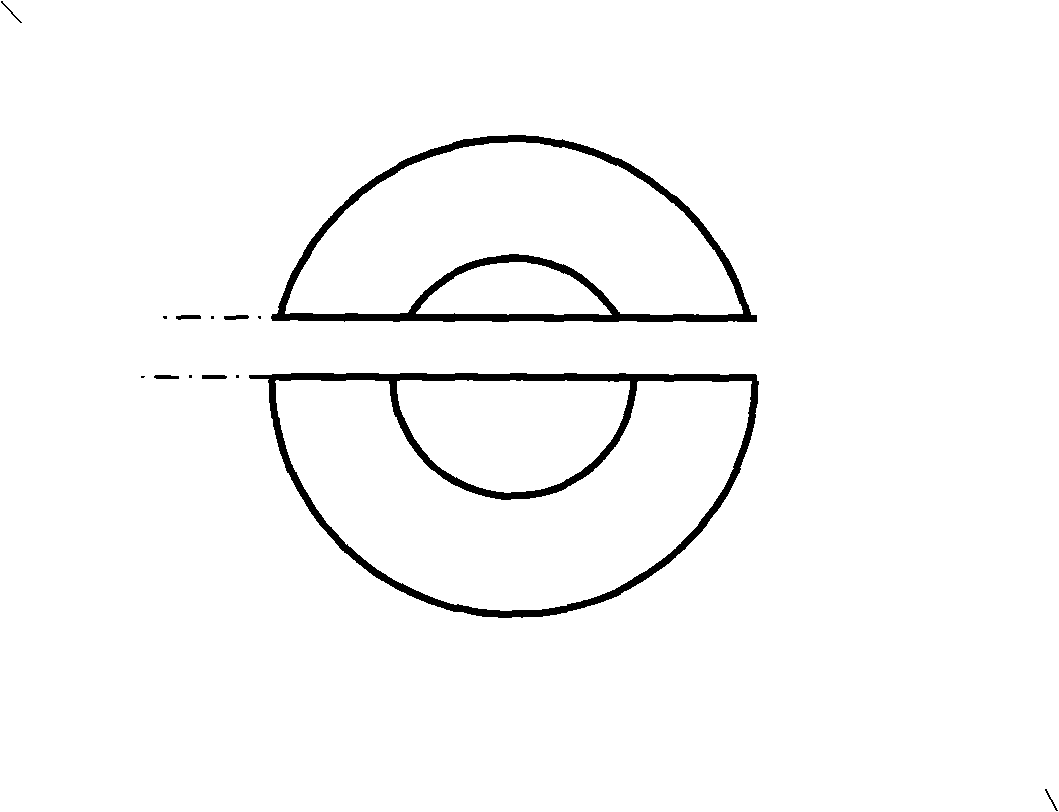

Image

Examples

Embodiment Construction

[0013] specific implementation

[0014] Taking the recycled bottle flake spinning production method of DTY75D / 72F as an example, the specific implementation steps are as follows: the recycled bottle flakes are used as processing materials, and after screening, they are transported to the crystallization bed for pre-crystallization (at a temperature of 275°C). The bottle flakes fall into the drying tower by their own weight (drying temperature 265°C), the moisture content of the bottle flakes is 25--30ppm, the bottle flakes are melted at high temperature (temperature is 287°C), extruded from the screw extruder, and passed Filter 3-stage filtration (filter precision: 50u; 40u; 30u), spinning box (temperature 287 ℃), high-pressure components (pressure 13---15mp), provided for the production of special-shaped 75D / 72F Production of special spinnerets, and then uniform airflow (wind temperature 23 ℃; wind speed 0.6-0.7m / s; wind speed unevenness ≤ 10%), after cooling and oiling (0.5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com