Filter press track for belt sludge dewatering equipment

A technology for sludge dehydration and equipment, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problem that the dehydration effect cannot be obviously improved, the continuous filter press time is short, Problems such as heavy crawler structure, to reduce mud running phenomenon, improve dehydration effect, light structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

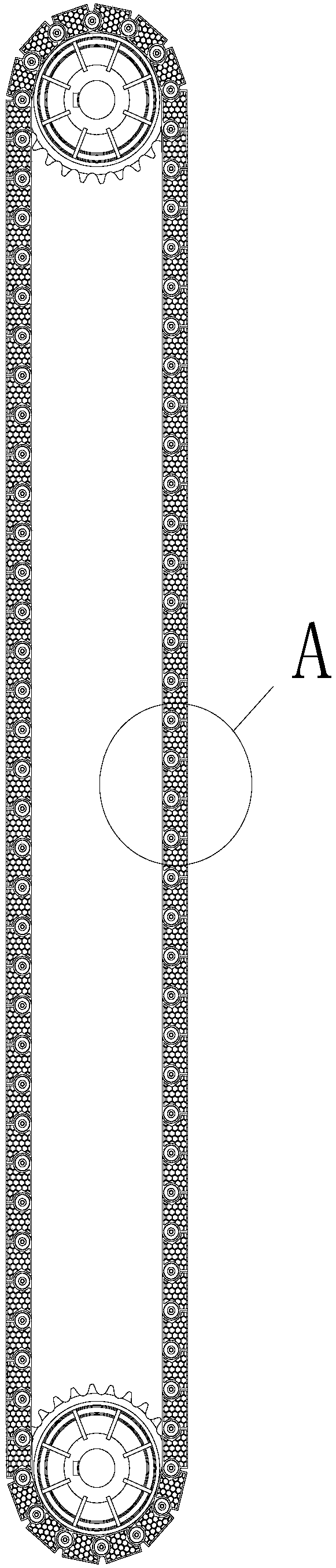

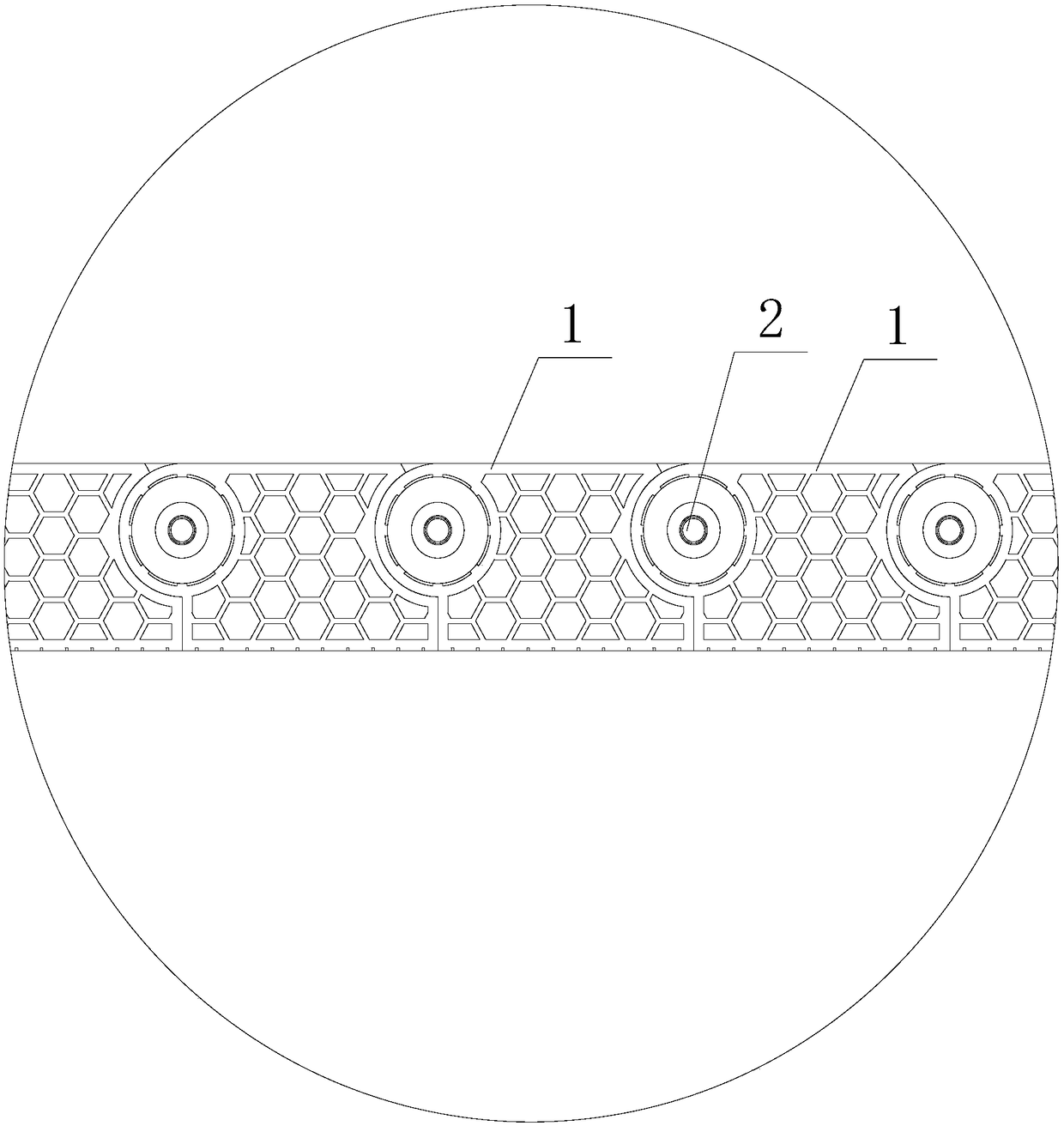

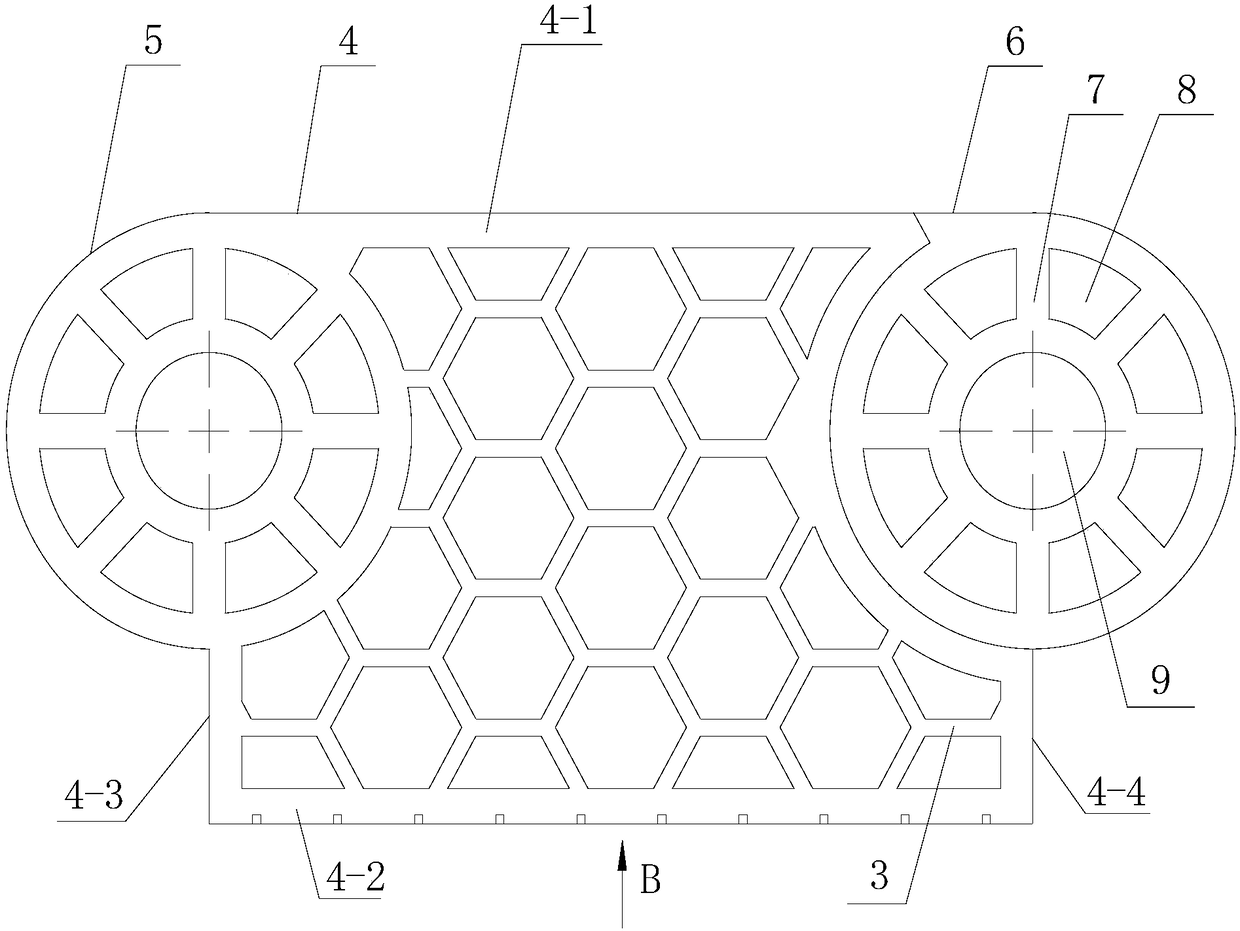

[0033] A kind of press filter track that present embodiment is used for belt type sludge dewatering equipment, such as figure 1 or figure 2 As shown, it includes a plurality of chain links 1, and each chain link is connected in turn to form a ring-shaped closed structure, and any two adjacent chain links are connected by a pin shaft 2, as shown in image 3 or Figure 5 As shown, the middle part of each chain link is the inner rib 3 of the honeycomb. Among them, the inner rib of the honeycomb uses the honeycomb structure to make the middle part of the chain link have a cavity structure, and uses honeycomb-shaped reinforcing ribs to support the outer surfaces of the chain link. This structure can reduce the weight of the chain link to a large extent on the premise of ensuring the rigidity of the chain link, so that the structure is light and the operation is stable.

[0034] Such as Figure 3-5 As shown, the chain link is an integrated structure, including the connected cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com