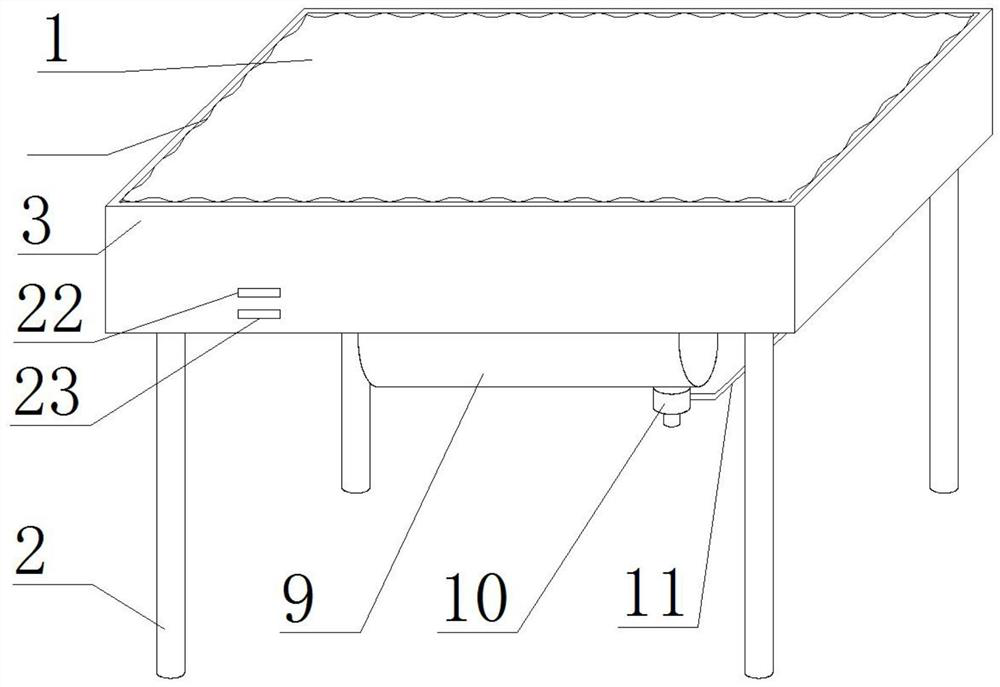

Integrated cutting table for live pig slaughtering

A technology for dividing tables and live pigs, which is applied in the direction of slaughtering, slaughtering accessories, slaughtering devices, etc. It can solve the problems of unfavorable cleaning of the corners of the table, unfavorable hygiene and safety of the dividing table, and unfavorable ground environmental sanitation, so as to facilitate the division operation and avoid Blockage, guarantee the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

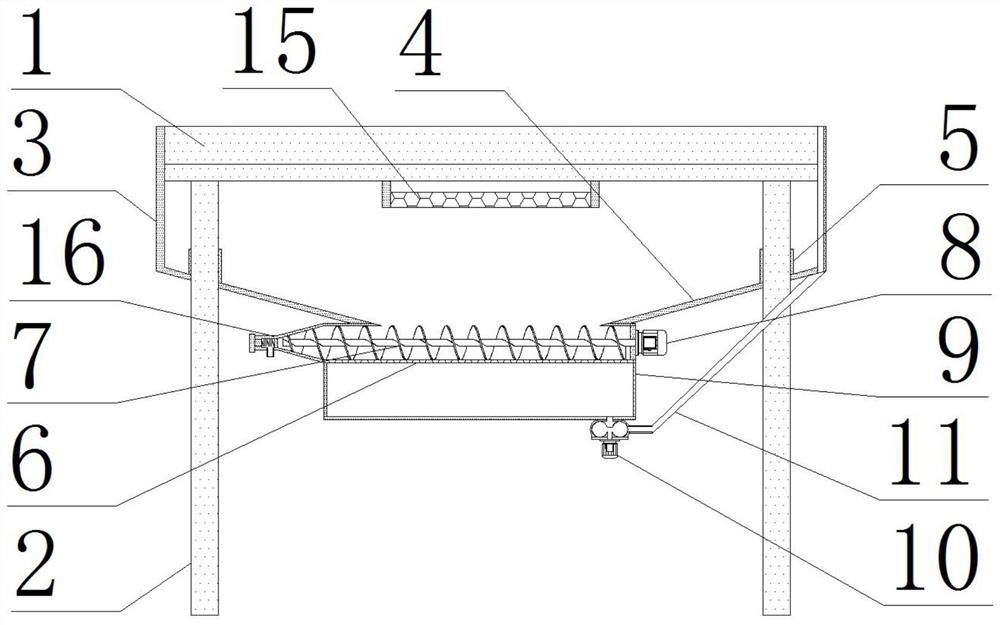

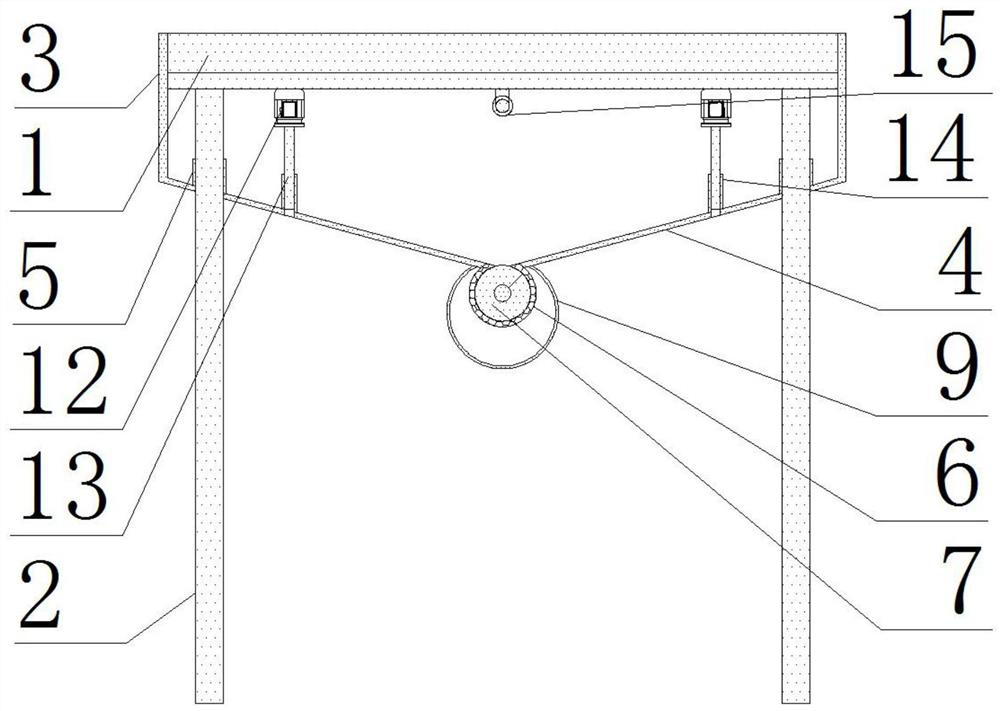

[0029] As a preferred embodiment of the present invention, one end of the spiral plate 7 is stuck on the inner side of the cone opening 16, and the other end of the spiral plate 7 passes through the filter cartridge 6 and the water tank 9 and is installed on the output of the motor one 8 by bolts. On the shaft, when the cleaning water flows into the filter cartridge 6 through the inclined plane 4, the disinfection lamp 15 sterilizes the cleaning water to prevent bacteria from contaminating the cleaning water, and the motor one 8 drives the spiral plate 7 to rotate in the filter cartridge 6. On the one hand, Use the spiral plate 7 to push and squeeze the cleaning water to the left, increase the filtration pressure of the cleaning water, improve the filtration efficiency of the cleaning water, and use the spiral plate 7 to scrape the debris, and scrape the debris and impurities into the cone mouth 16, Avoid filter cartridge 6 clogging.

[0030]As a preferred embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com