Garbage storage warehouse

A technology for garbage and garbage trucks, applied in the field of garbage storage, can solve the problems of reducing domestic garbage collection and storage, hoisting operation and hoisting operation time waste, and reducing the total effective storage capacity of garbage storage, so as to prolong the static drainage time and improve the effective storage capacity. Storage capacity, the effect of reducing energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

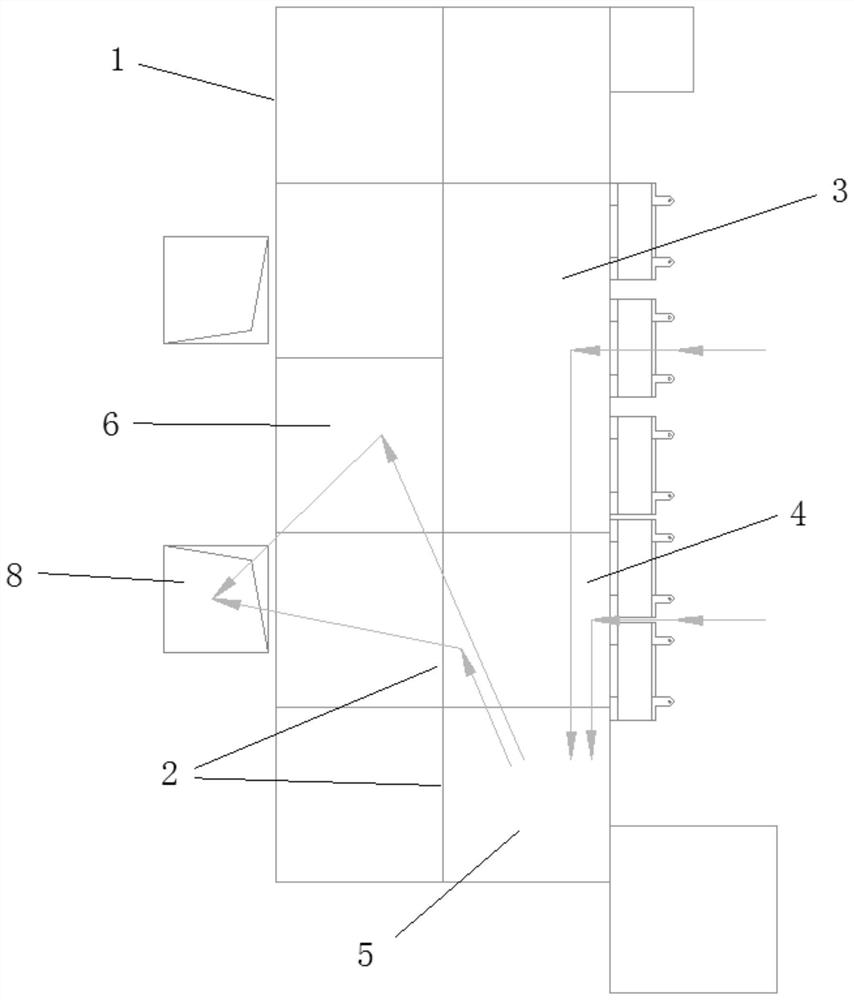

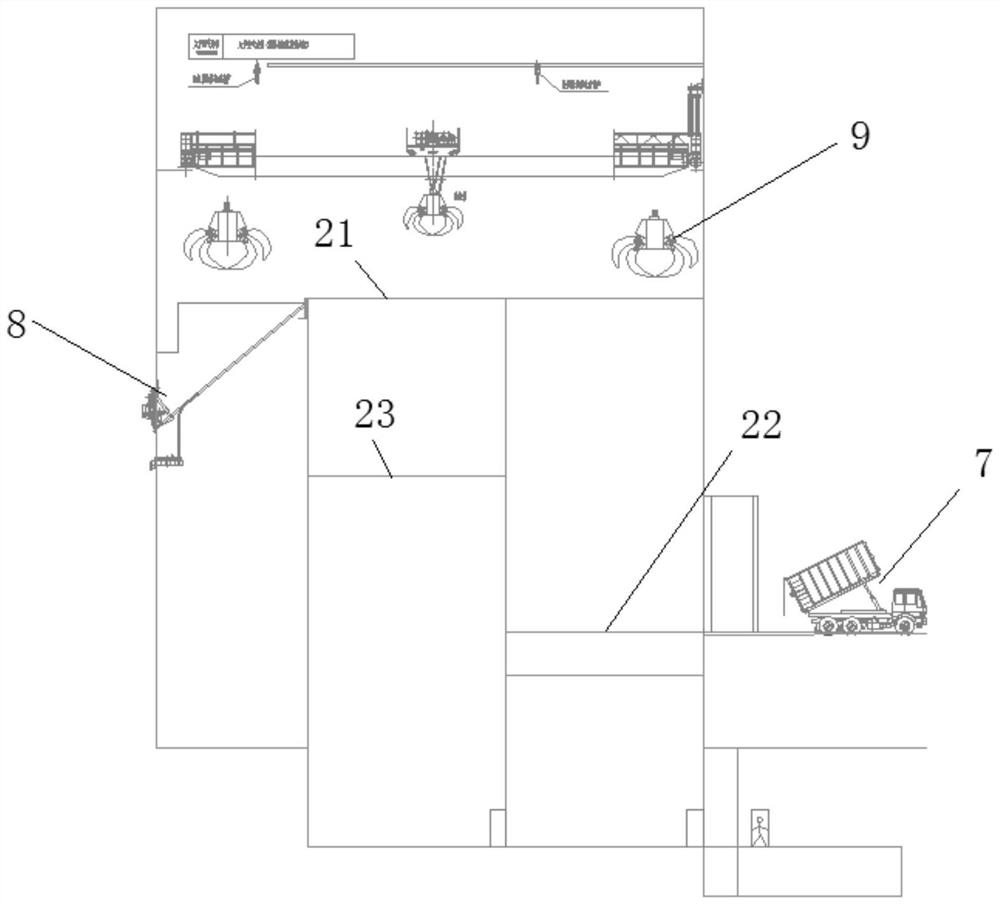

[0037] In order to improve the efficiency of domestic garbage fermentation, especially anaerobic fermentation, and the effective storage capacity in the garbage storage, this embodiment provides a garbage storage, please refer to figure 1 with figure 2 As shown, the storage warehouse 1 is included, and several partitions 2 are arranged in the storage warehouse 1, and the storage warehouse 1 is divided into several upper open compartments, and the compartments are divided into unloading compartment 3 and turnover compartment 4. , the fermentation cabin 5 and the loading cabin 6, wherein the loading cabin 6 and the turnover cabin 4 are all adjacent to the unloading cabin 3.

[0038] see you again figure 1 with figure 2 As shown, the storage warehouse 1 is divided into two equally divided columns by the partition plate 2 in the longitudinal direction, and each column is further divided into 5 rows to form 10 equal storage spaces. The two storage spaces in the middle part are...

Embodiment 2

[0057] Compared with Embodiment 1, most of them are the same, except that the storage warehouse 1 in the present embodiment is divided into seven compartments by the partition plate 2, wherein, four are fermentation compartments 5, and the remaining three are discharge compartments respectively. cabin 3, turnover cabin 4 and feeding cabin 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com