Filter press

A technology of filter press and filter chamber, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., which can solve the problems of difficult filter cloth replacement, complicated automatic control, and high replacement cost, and achieve simple and convenient operation monitoring and cleaning The method is scientific and effective, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

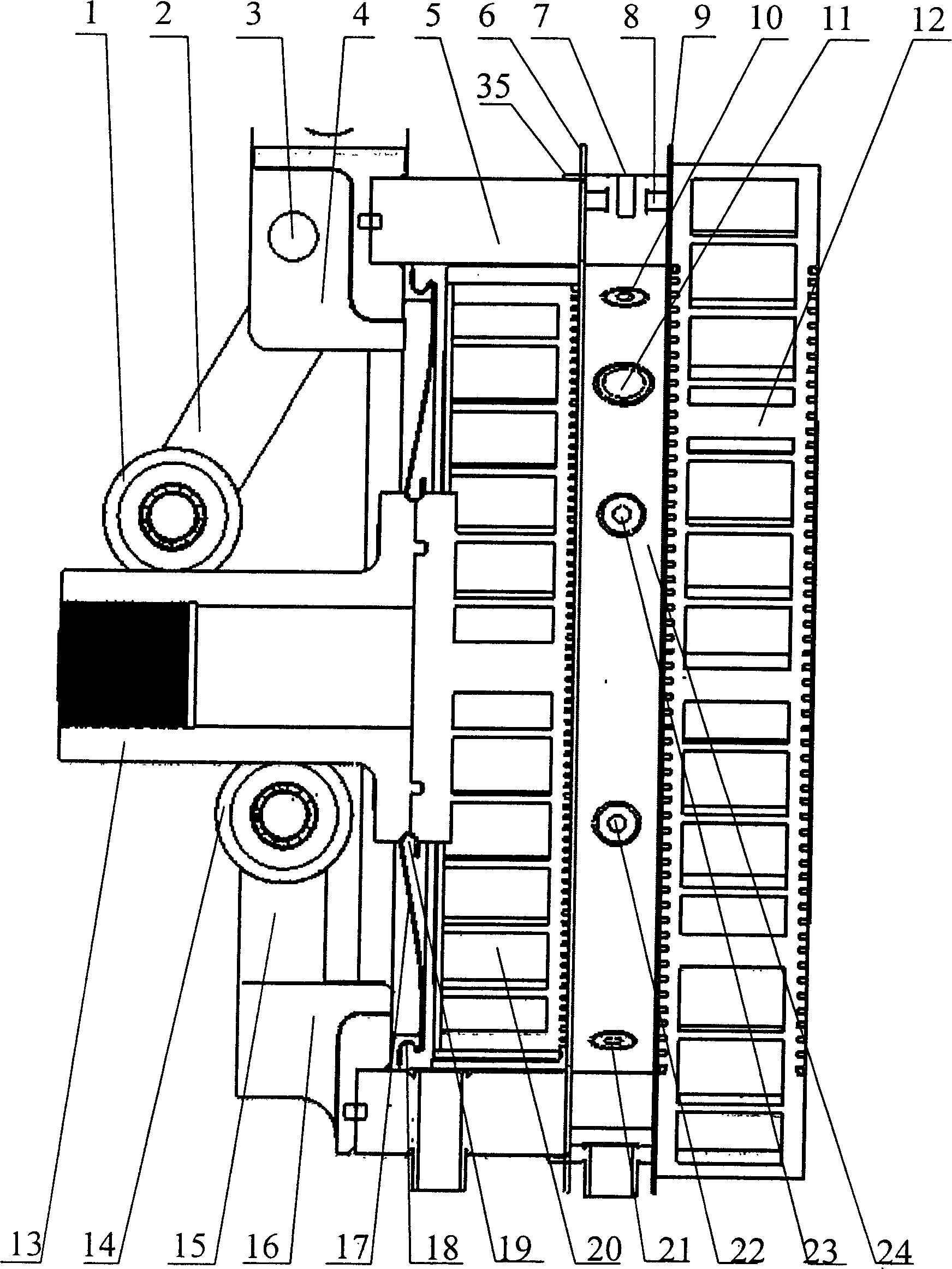

[0039] Example. Filter press combined with two single chamber machines

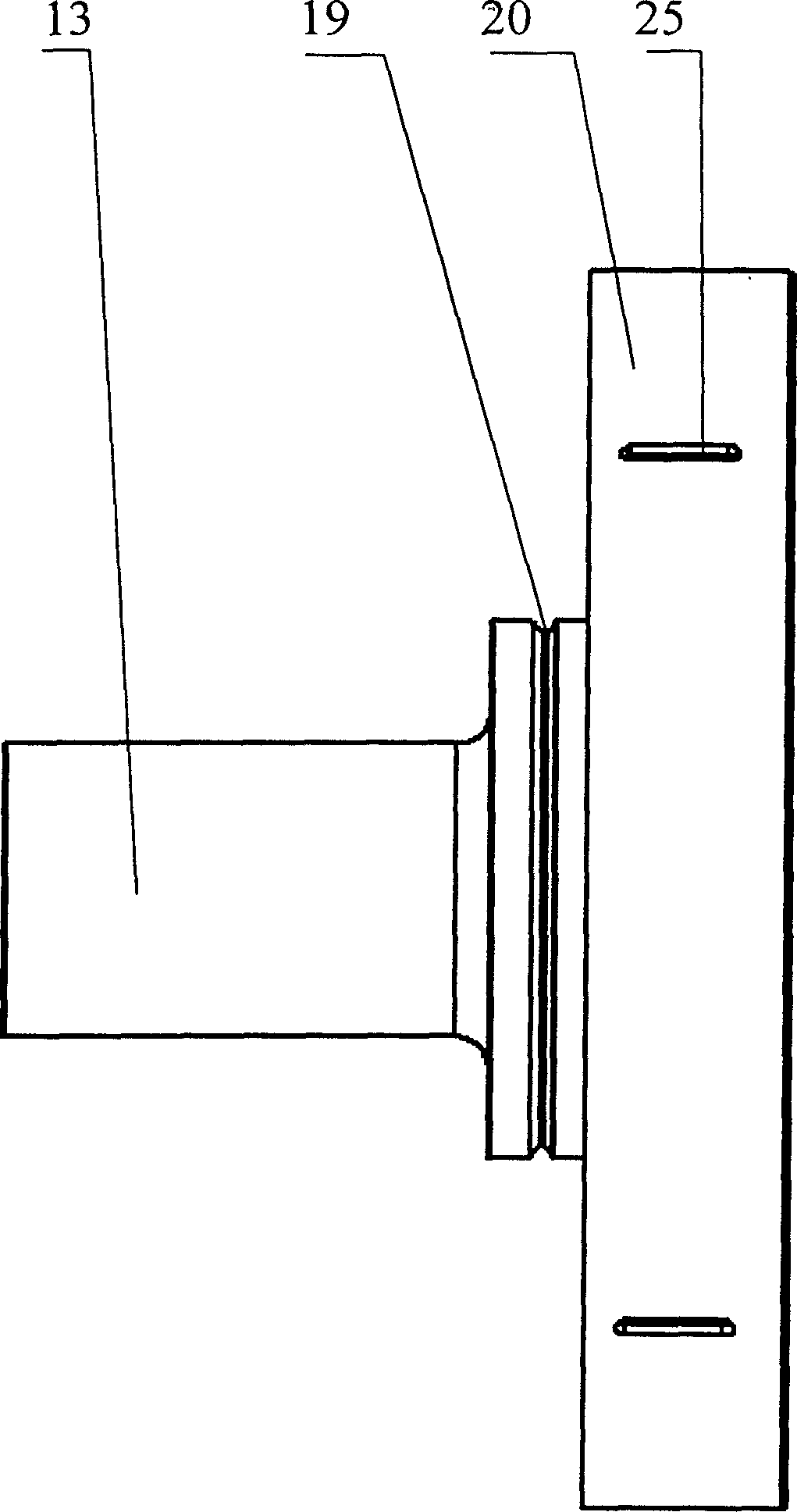

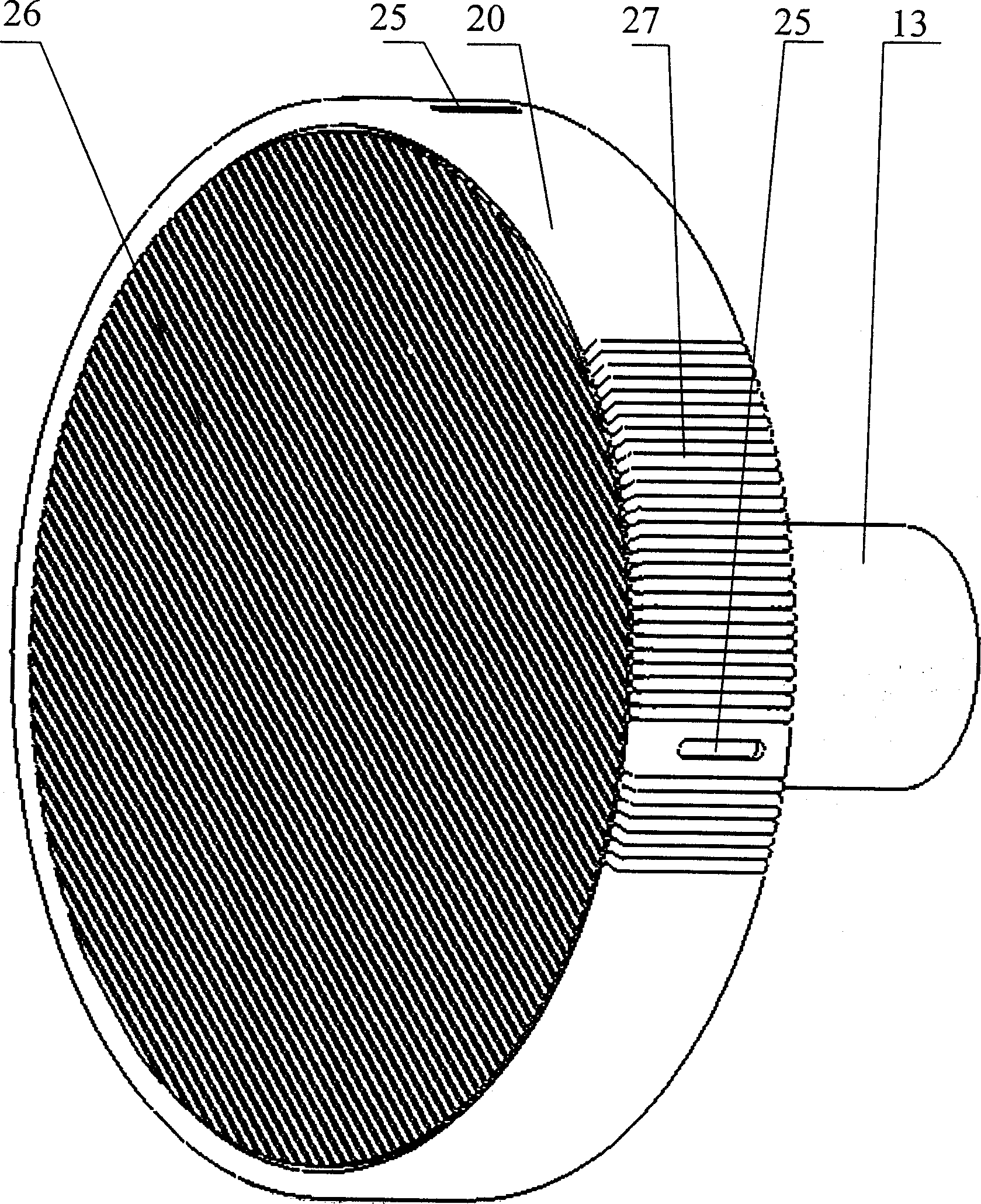

[0040] A filter press combined with two single-chamber machines, as shown in the accompanying drawings, it has a single-chamber machine, each single-chamber machine consists of a fixed filter plate 12, a multifunctional filter chamber ring 7, a moving frame 5 and The movable filter plate 20 is composed of at least three connecting rod installation holes 45 on the outer periphery of the fixed filter plate 12, and the fixed filter plate 12 has a left inlet liquid inlet 46, a left filtrate outlet 47 and a right inlet liquid inlet 48 , the right side filtrate outlet 49, the positive and negative sides of the fixed filter plate 12 each have a circle of fixed filter plate filter chamber sealing surface 43, and there are circular or The diamond-shaped particles constitute the drainage groove 44, which is a passage for fluid to enter and exit quickly. The plate filter cloth 9 is clamped and fixed, the filter cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com