Faucet filter element structure

A faucet and filter element technology, which is applied in the field of faucet filter element structure, can solve the problems of lack of impact resistance, incomplete filtration, and poor anti-scaling ability, and achieve good anti-corrosion performance, excellent adsorption capacity, and anti-scale effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

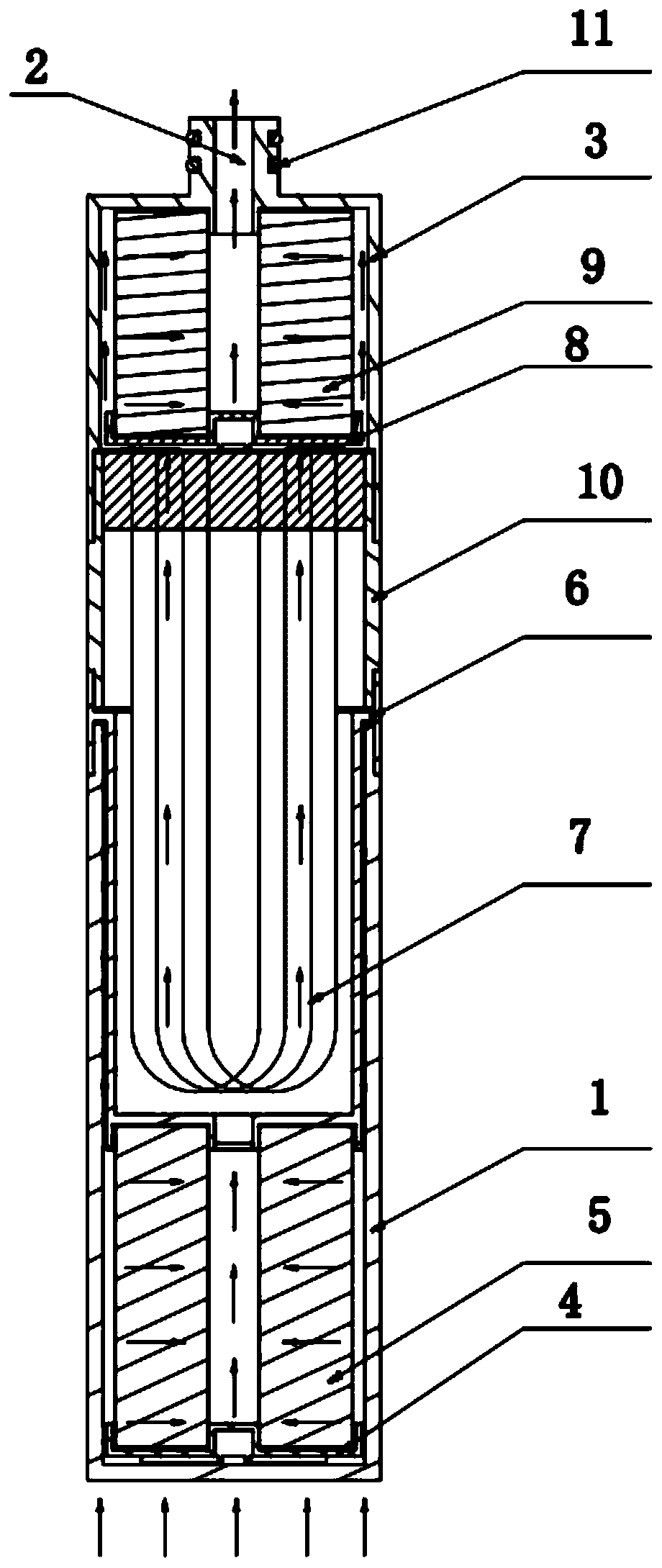

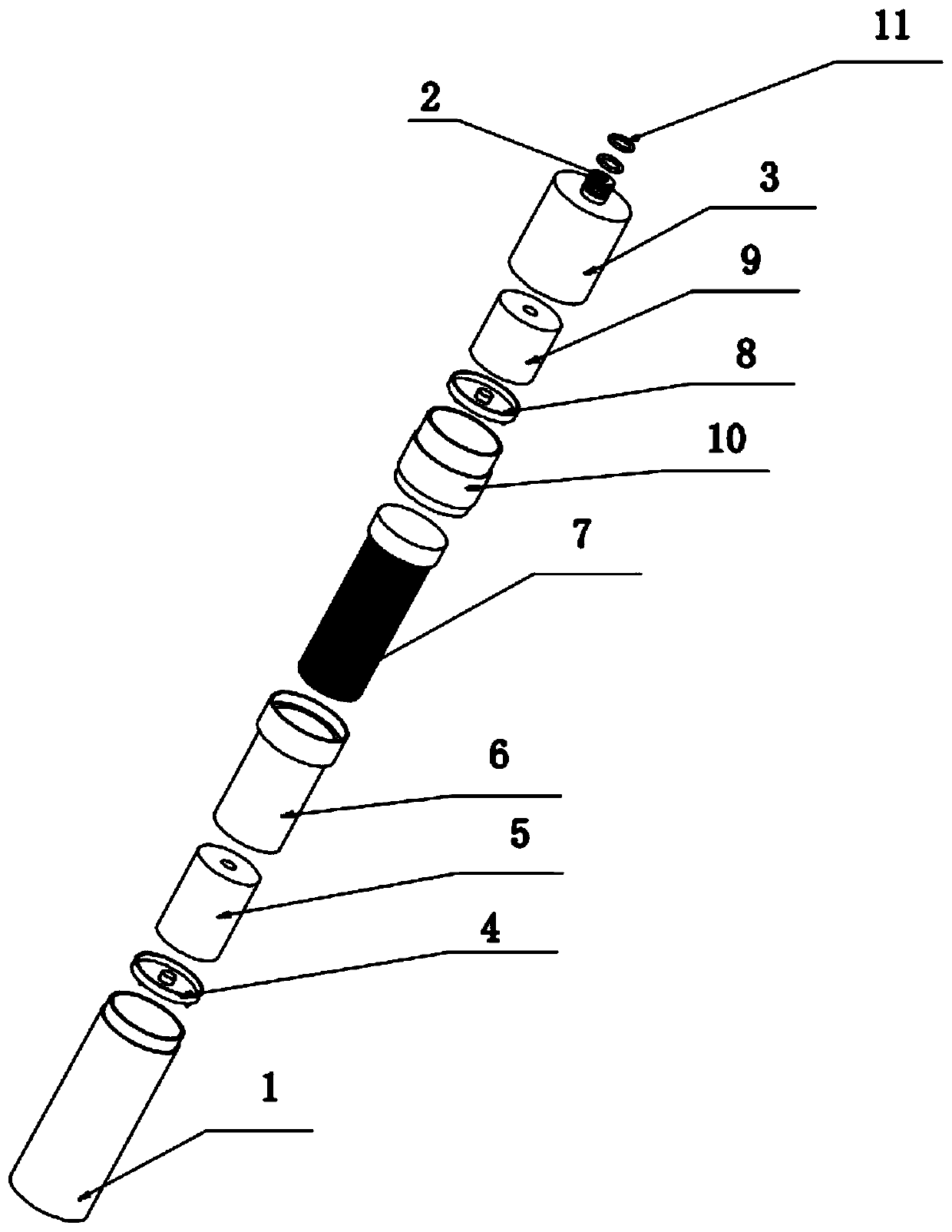

[0023] A kind of faucet filter element structure described in this embodiment 1, such as figure 1 with figure 2 As shown, it includes a PE sintered filter element 1 with a water inlet (not shown in the figure), a rear housing 3 that is installed in conjunction with the PE sintered filter element and has a water outlet 2; the bottom of the PE sintered filter element is provided with a front plug 4, and the front The plug is supported by the pre-activated carbon fiber 5 placed in the lower part of the PE sintered filter element. The upper part of the PE sintered filter element is provided with a pre-connecting plate 6 above the pre-activated carbon fiber. The pre-connecting plate is equipped with an ultrafiltration membrane wire 7. The top of the ultrafiltration membrane wire is provided with a rear plug 8 located in the rear casing, and the rear plug supports a rear activated carbon fiber 9 located in the rear casing; between the front plug and the bottom of the PE sintered fi...

Embodiment 2

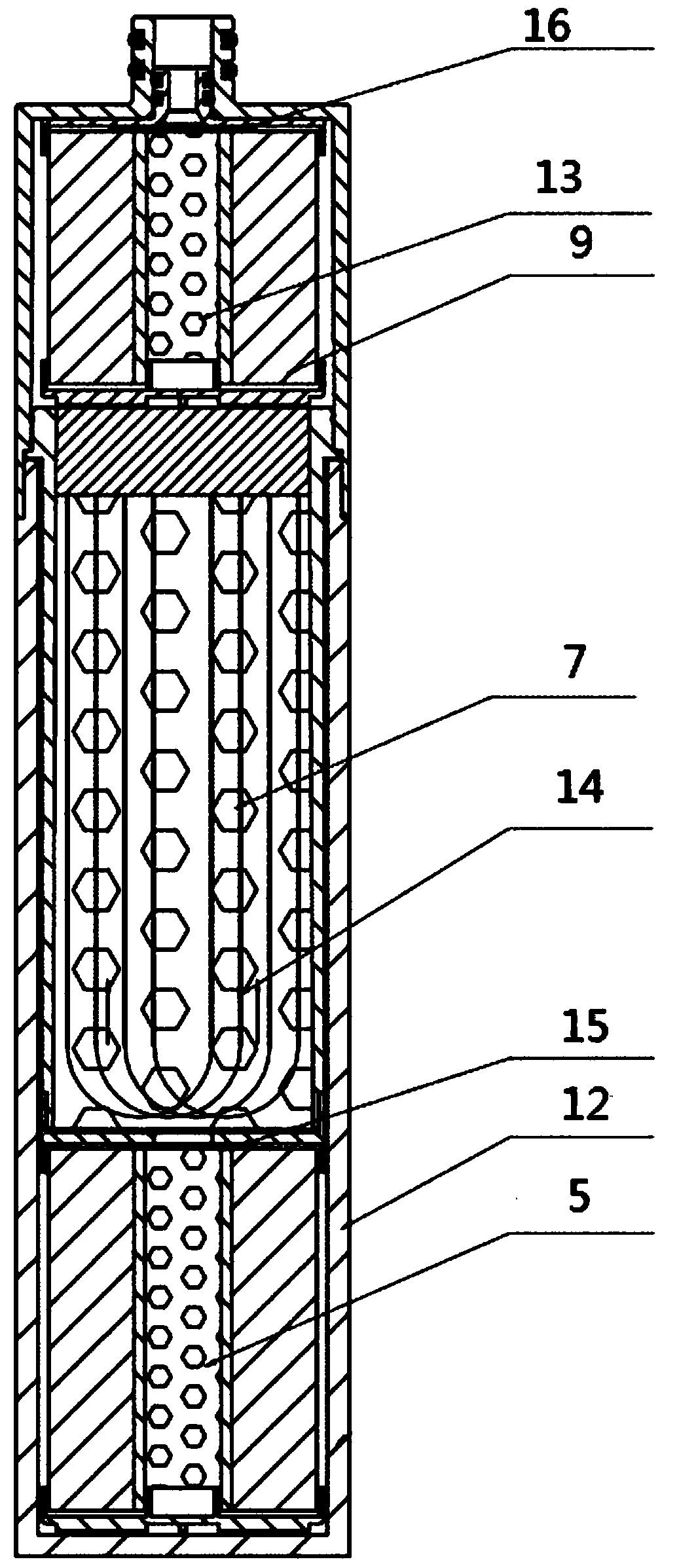

[0030] Present embodiment 2 changes on the basis of implementation 1, the specific difference is as follows: as image 3 As shown, the center position of the front activated carbon fiber 5 is filled with a front softening resin 12, and the center position of the rear activated carbon fiber 9 is filled with a post softening resin 13. Softening resin is also called taste factor, which has the advantages of softening water quality and improving taste.

[0031]In this embodiment, the ultrafiltration membrane filament 7 is filled with a scale-inhibiting filter material 14 . Because minerals such as calcium and magnesium are rich in tap water, they exist in the form of ions, which is conducive to human body absorption. Once scale is formed in water, it will cause harm to the human body, because scale is a kind of insoluble salt, whether it is scale in the form of calcium carbonate and magnesium carbonate, or scale in the form of calcium sulfate and magnesium sulfate, the human body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com