Excrement residue sterilization and deodorization method

The technology of manure residue and deodorant is applied in the field of manure residue sterilization and deodorization, which can solve the problems of long processing time, simple processing process, destroying the circulation function of agricultural ecosystem, etc. The effect of shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Collection: collect the feces and slag discharged from the farm, collect them in the sump, and stir them evenly;

[0037] (2) Preliminary deodorization:

[0038] (21) Preparation of deodorant: take by weighing orange peel powder 1kg, silicon powder 10kg, mulberry leaf powder 5kg and pine needle powder 3kg, mix well, and set aside;

[0039] (22) Add deodorant in sump, add 30kg deodorant for every 1000kg dung, stir evenly, obtain preliminary deodorized dung;

[0040] (3) Anaerobic reaction stage:

[0041] (31) Preparation of microbial decomposition agent: Weigh 1kg of actinomycetes, 3kg of Saccharomyces cerevisiae, 1kg of Bacillus pumilus, 5kg of Bacillus coagulans, 5kg of Bacillus stearothermophilus and 10kg of Clostridium sporogenes, mix well, and set aside;

[0042] (32) Pump the preliminary deodorized dung into the anaerobic reaction tank, add 0.5 kg of microbial decomposition agent per 1000 kg of preliminary deodorized dregs to carry out anaerobic fermentation,...

Embodiment 2

[0047] (1) Collection: collect the feces and slag discharged from the farm, collect them in the sump, and stir them evenly;

[0048] (2) Preliminary deodorization:

[0049] (21) Preparation of deodorant: take orange peel powder 10kg, silicon powder 20kg, mulberry leaf powder 15kg and pine needle powder 5kg, mix and set aside;

[0050] (22) add deodorant in sump, add deodorant 100kg in every 1000kg dung, stir, obtain preliminary deodorized dung;

[0051] (3) Anaerobic reaction stage:

[0052] (31) Preparation of microbial decomposition agent: take 3kg of actinomycetes, 5kg of Saccharomyces cerevisiae, 5kg of Bacillus pumilus, 10kg of Bacillus coagulans, 10kg of Bacillus stearothermophilus and 20kg of Clostridium sporogenes, mix well, and set aside;

[0053] (32) Pump the preliminary deodorized dung into the anaerobic reaction tank, add 1.5 kg of microbial decomposition agent to each 1000 kg of preliminary deodorized dung for anaerobic fermentation, the fermentation temperatur...

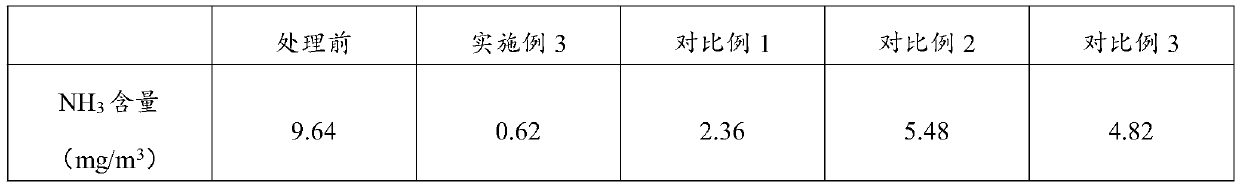

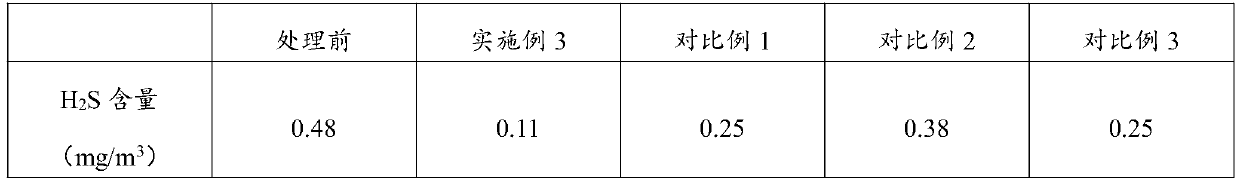

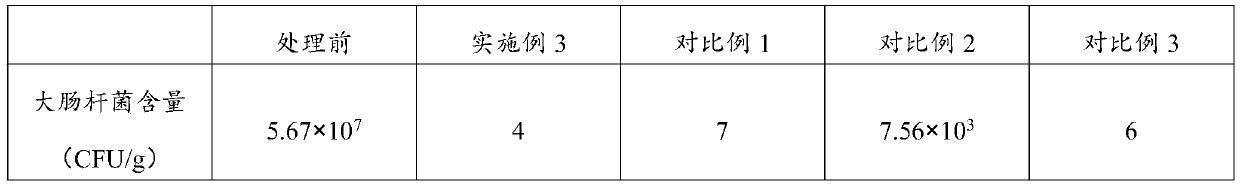

Embodiment 3

[0058] (1) Collection: collect the feces and slag discharged from the farm, collect them in the sump, and stir them evenly;

[0059] (2) Preliminary deodorization:

[0060] (21) Preparation of deodorant: take orange peel powder 5kg, silicon powder 15kg, mulberry leaf powder 10kg and pine needle powder 4kg, mix and set aside;

[0061] (22) add deodorant in sump, add 60kg deodorant in every 1000kg dung, stir, obtain preliminary deodorized dung;

[0062] (3) Anaerobic reaction stage:

[0063] (31) Preparation of microbial decomposition agent: take by weighing 2kg of actinomycetes, 4kg of Saccharomyces cerevisiae, 3kg of Bacillus pumilus, 7kg of Bacillus coagulans, 7kg of Bacillus stearothermophilus and 15kg of Clostridium sporogenes, mix well, and set aside;

[0064] (32) Pump the preliminary deodorized dung into the anaerobic reaction tank, add 1 kg of microbial decomposition agent to every 1000 kg of preliminary deodorized dung for anaerobic fermentation, the fermentation tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com