Cylindrical material-issuing tank of a plurality of air distributors and material-issuing tubes and multi-path material-issuing method thereof

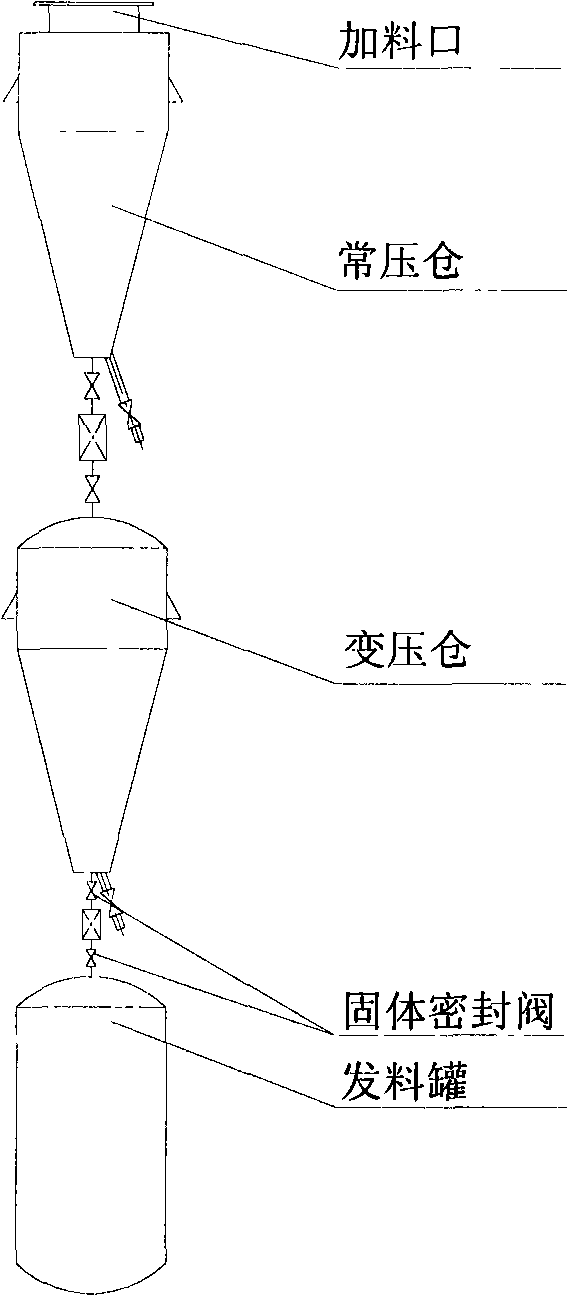

A cylindrical and discharge pipe technology is applied in the fields of clean coal combustion power generation and coal chemical industry, which can solve the problems of low space utilization rate of conical feeding tank and coal powder bridging, saving installation space and high space utilization rate. , The effect of simplifying the multi-channel coal supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

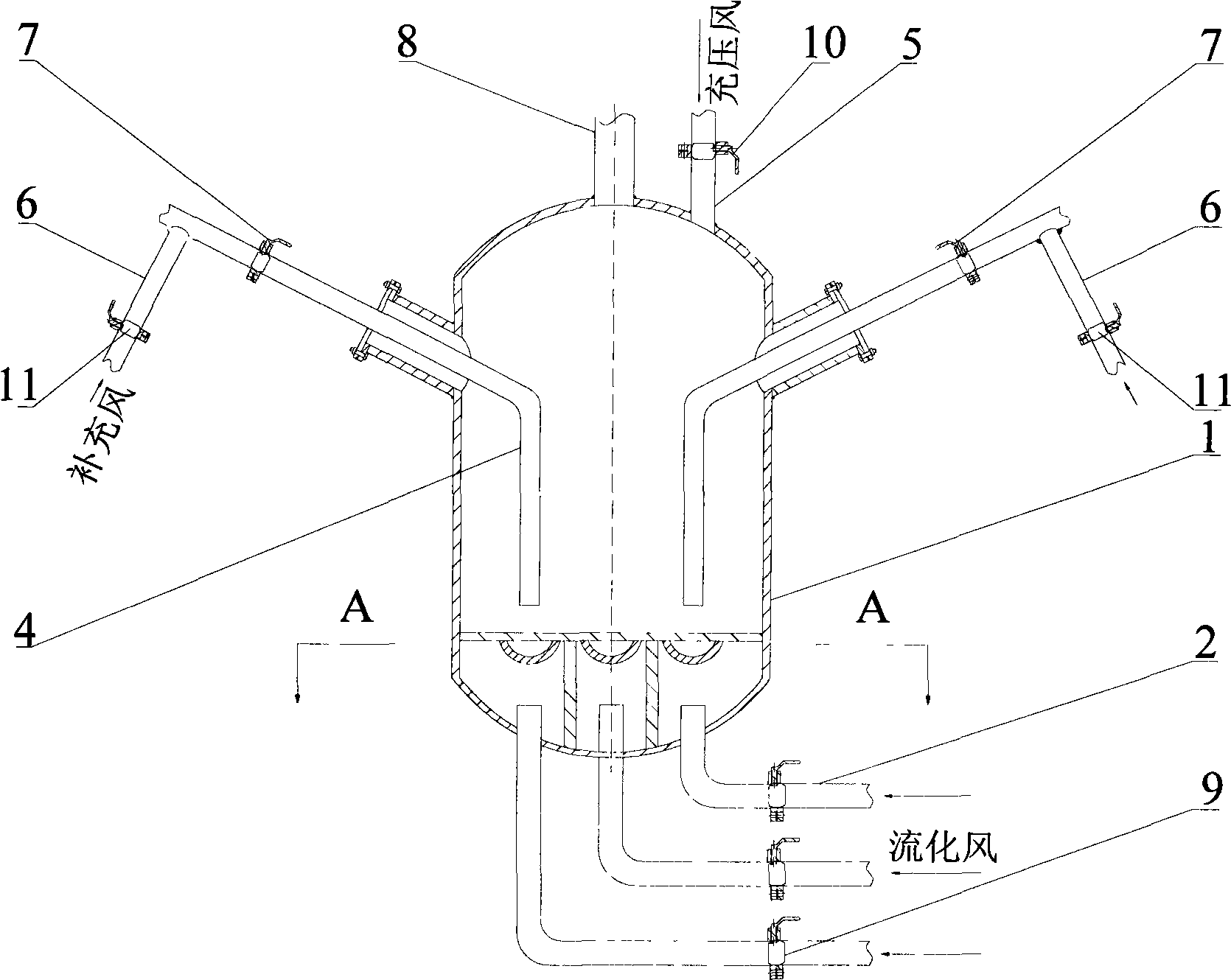

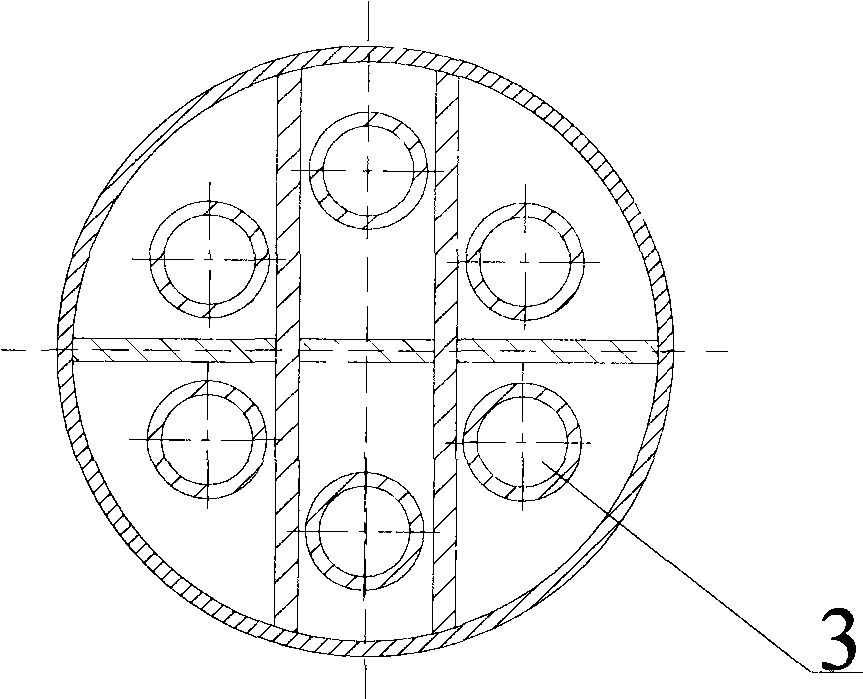

[0016] The cylindrical material delivery tank device of the present invention consists of a cylindrical material tank body 1, a fluidized air duct 2, an air distribution plate 3, a discharge pipe 4, a pressurized air pipe 5, a supplementary air pipe 6, a discharge control valve 7, The coal drop port 8 is formed. Multiple fluidization air ducts are arranged at the bottom of the material tank, and each fluidization air duct is equipped with a fluidization air duct valve 9 . The fluidized air pipe is connected with the separated air chambers at the bottom of the material tank, and above the air chambers is a group of flat-bottomed conical air distribution plates. One air distribution plate corresponds to one fluidized air duct and a discharge pipe is arranged above each air distribution plate, and each discharge pipe is equipped with a discharge control valve. The charging air duct is arranged above the material tank, and the supplementary air duct is arranged at the outlet of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com