Organic-inorganic environmentally-friendly pollution-free compound fertilizer

A kind of compound fertilizer and inorganic technology, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilizer mixture, etc., can solve the problem of organic fertilizer granulation difficulty, etc., achieve the effect of not easy to agglomerate, high strength, and improve photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

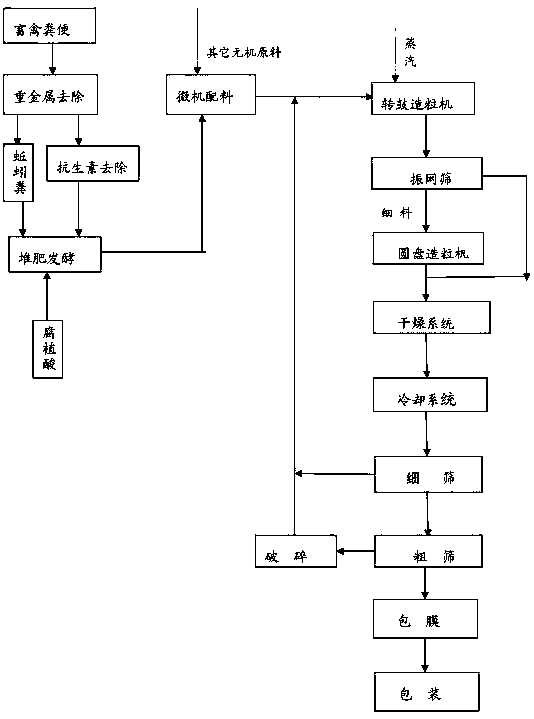

[0061] The preparation method of described organic-inorganic environment-friendly pollution-free compound fertilizer comprises the following steps:

[0062] (1) Removal of heavy metals from livestock manure

[0063] 1.1 Add amino acids and ethylenediaminetetraacetic acid to livestock and poultry manure with a water content of 60-70% and an organic matter content of 40-42%, and use chemical extraction method to soak and extract amino acids while using chelating agent ethylenediaminetetraacetic acid to chelate livestock Heavy metal ions in poultry manure;

[0064] 1.2 Dehydrate the treated livestock and poultry manure through a sludge dewatering machine to remove the heavy metal ions contained in the livestock and poultry manure, and obtain a water content of 40-50% and remove heavy metals from the livestock and poultry manure;

[0065] (2) Preparation of vermicompost

[0066] 2.1 Add the heavy metal ion wastewater in step (1) to the mixture of crushed crop straw, bean cake an...

Embodiment 1

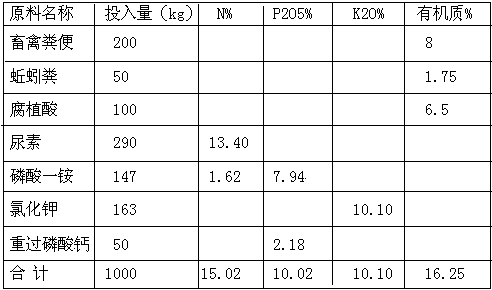

[0093] The content of nitrogen, phosphorus and potassium in the preparation is 15%-10%-10%, and the content of organic matter is 16%. Take the consumption quota of raw materials for 1 ton of products as an example:

[0094]

[0095] Specific production process:

[0096] (1) Removal of heavy metals from livestock manure

[0097] 1.1 Add 2kg of amino acid and 0.8kg of ethylenediaminetetraacetic acid to 200kg of livestock and poultry manure with a moisture content of 60% and an organic matter content of 40%, and use chemical extraction method to soak and extract amino acids while using chelating agent ethylenediaminetetraacetic acid to chelate livestock Heavy metal ions in poultry manure;

[0098] 1.2 Dehydrate the treated livestock and poultry manure through a sludge dewatering machine to remove the heavy metal ions contained in the livestock and poultry manure, and obtain a water content of 45% and remove heavy metals from the livestock and poultry manure;

[0099] (2) Pre...

Embodiment 2

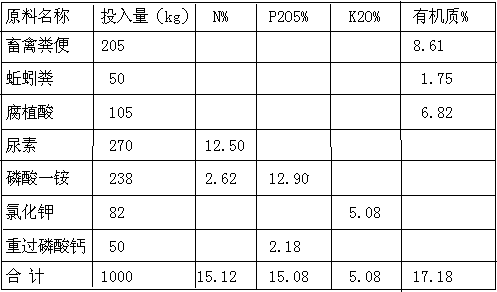

[0117] The content of nitrogen, phosphorus and potassium in the preparation is 15%-15%-5%, and the content of organic matter is 17%. Take the raw material consumption quota of 1 ton product as an example:

[0118]

[0119] Specific production process:

[0120] (1) Removal of heavy metals from livestock manure

[0121] 1.1 Add 2.05kg of amino acid and 0.82kg of ethylenediaminetetraacetic acid to 205kg of livestock and poultry manure with a water content of 60% and an organic matter content of 42%, and use chemical extraction method to soak and extract amino acids and use chelating agent ethylenediaminetetraacetic acid to chelate Heavy metal ions in livestock manure;

[0122] 1.2 Dehydrate the treated livestock and poultry manure through a sludge dewatering machine to remove the heavy metal ions contained in the livestock and poultry manure, and obtain a water content of 45% and remove heavy metals from the livestock and poultry manure;

[0123] (2) Preparation of vermicompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com