Hot air circulation system for tobacco drying

A technology of circulation system and heat pump system, which is applied in tobacco drying, drying gas arrangement, local agitation dryer, etc., can solve the problems of large energy consumption, achieve high energy efficiency, reduce operating costs, and reduce loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

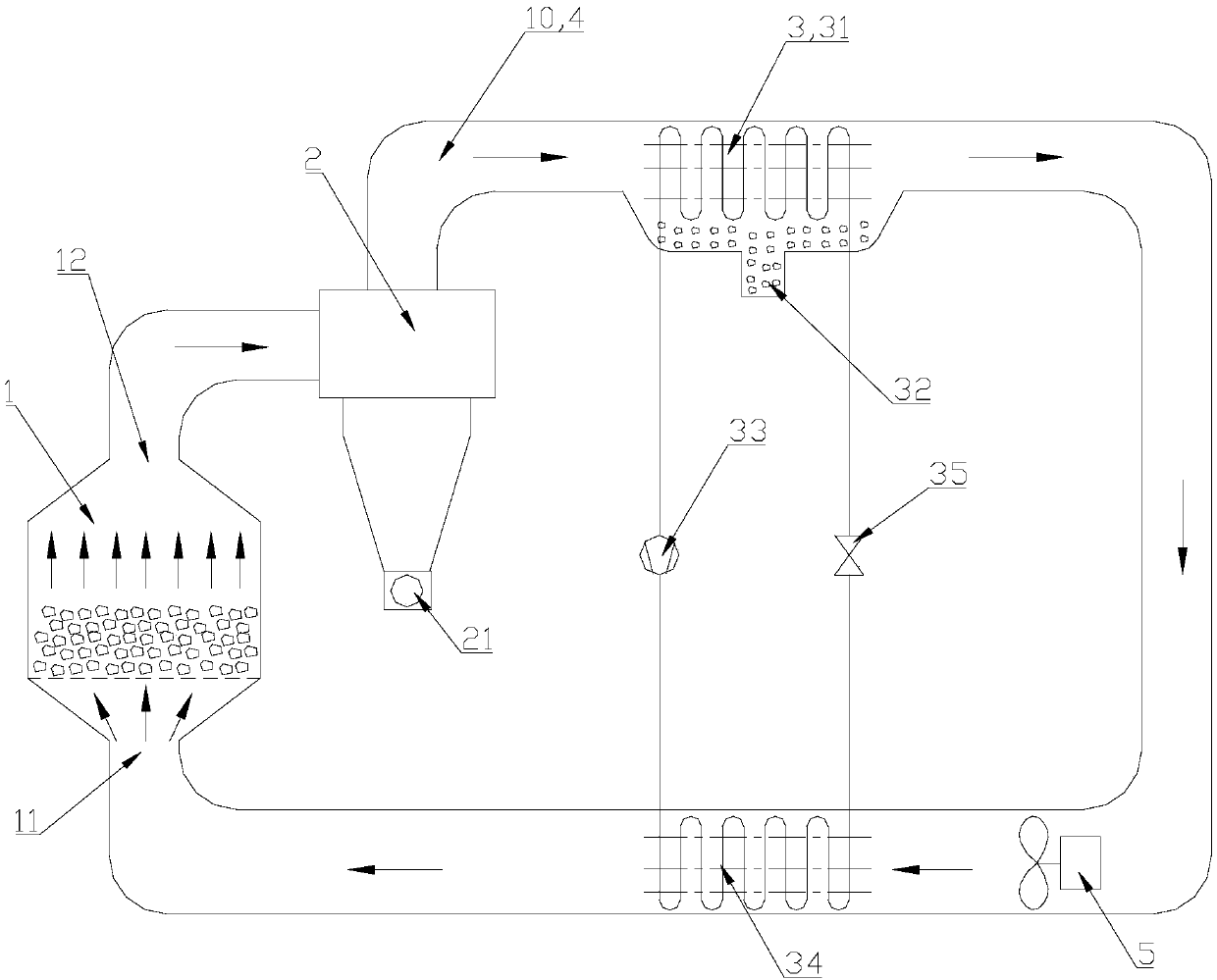

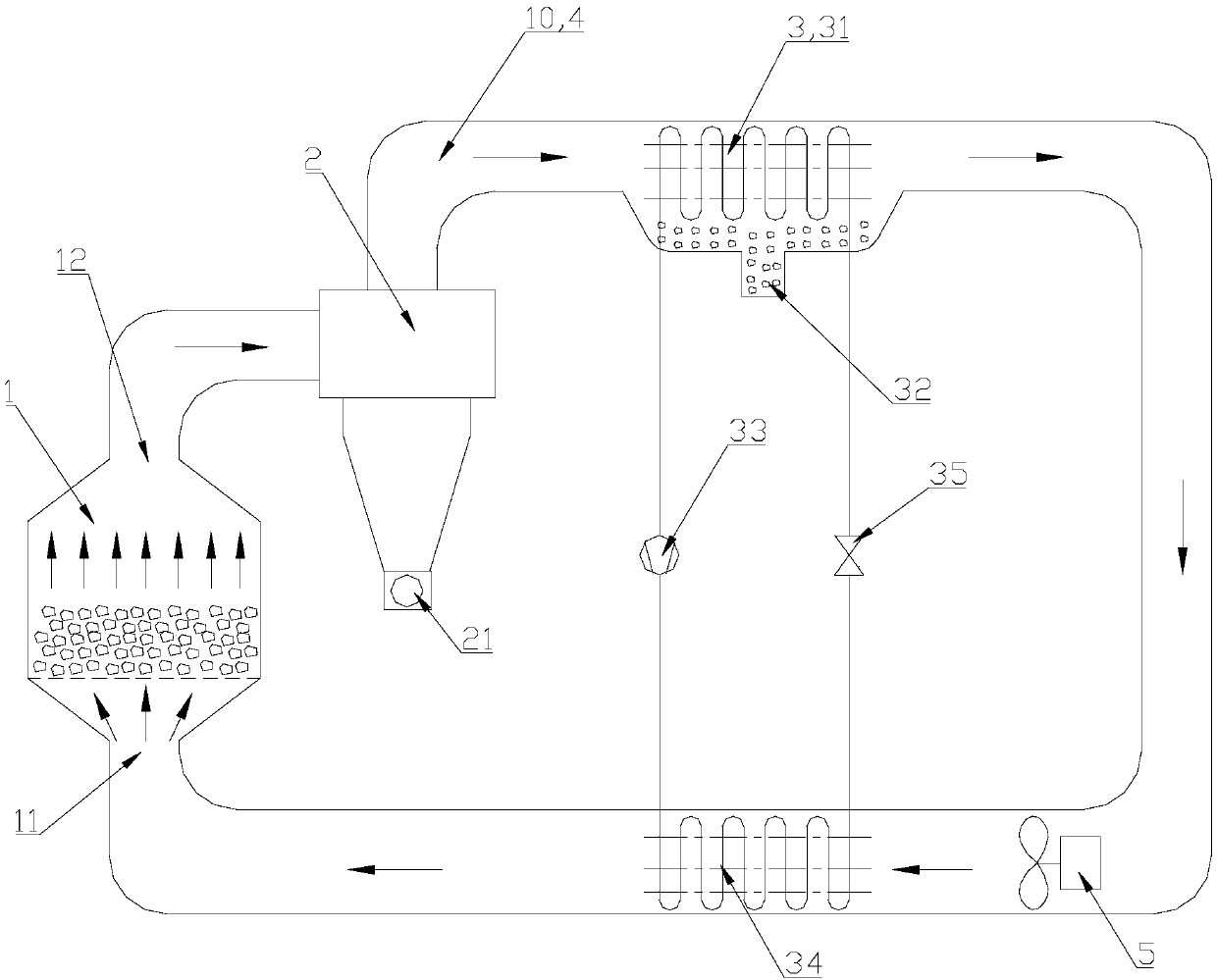

[0033] Such as figure 1 As shown, a tobacco drying hot air circulation system 10 is introduced in this embodiment, comprising a drying chamber 1, a circulating air duct 4 and a heat pump system 3, the drying chamber 1 is provided with an air inlet 11 and an air outlet 12, and the circulating air duct 4 is provided with Outside the drying chamber 1, both ends are respectively connected with the air inlet 11 and the air outlet 12 of the drying chamber 1 to form a circulating air path with the drying chamber 1. At least part of the heat pump system 3 is arranged in the circulating air duct 4, and the circulating air duct After the airflow in 4 dries the materials in the drying chamber 1, the part of the heat pump system 3 in the circulating air duct 4 is dehumidified and heated to become a medium-temperature dry airflow, and then flows back into the drying chamber 1 for the next drying cycle . The degradation reaction of effective ingredients, nutritional ingredients and bioacti...

Embodiment 2

[0040] Such as figure 1As shown, in this embodiment, the heat pump system 3 further includes a compressor 33 and a throttle valve 35, the evaporator 31, the compressor 33, the condenser 34 and the throttle valve 35 are connected in sequence, and one end of the compressor 33 is connected to the The evaporator 31 is connected, and the other end is connected with the condenser 34; one end of the throttle valve 35 is connected with the evaporator 31, and the other end is connected with the condenser 35. The machine 33, the condenser 34, and the throttle valve 35 circulate in the evaporator 31 to form a heat pump cycle.

[0041] In this embodiment, the low-pressure and low-temperature liquid working medium in the heat pump system 3 flows into the evaporator 31, and absorbs the heat of the low-temperature and humid airflow in the evaporator 31, so that the low-temperature and humid airflow is further cooled below the dew point temperature. The low-pressure liquid working medium is ...

Embodiment 3

[0043] Such as figure 1 As shown, in this embodiment, a fan 5 is also provided in the circulating air duct 4 , and the fan 5 is used to control the flow direction of the airflow in the circulating air duct 4 .

[0044] In this embodiment, the fan 5 is arranged downstream of the evaporator 31 and upstream of the condenser 34 to control the flow of air in the circulating air duct 4 from the evaporator 31 to the direction of the condenser 34 .

[0045] In this embodiment, a dust remover 2 is also provided in the circulating air duct 4, and the dust remover 2 is arranged at the upstream of the evaporator 31 and at the air outlet 12 of the drying chamber 1, so as to prevent the air that flows out of the drying chamber 1 and is about to enter the evaporation process. The airflow of the device 31 is subjected to dust removal treatment.

[0046] In this embodiment, the dust remover 2 is also provided with a dust discharge port 21 , and the dust discharge port 21 is provided through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com