Method for manufacturing aroma-increasing moisture retention cigarette paper

A technology for enhancing aroma, moisturizing, and cigarette paper, which is applied in the directions of papermaking, special paper, textiles, and papermaking. Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

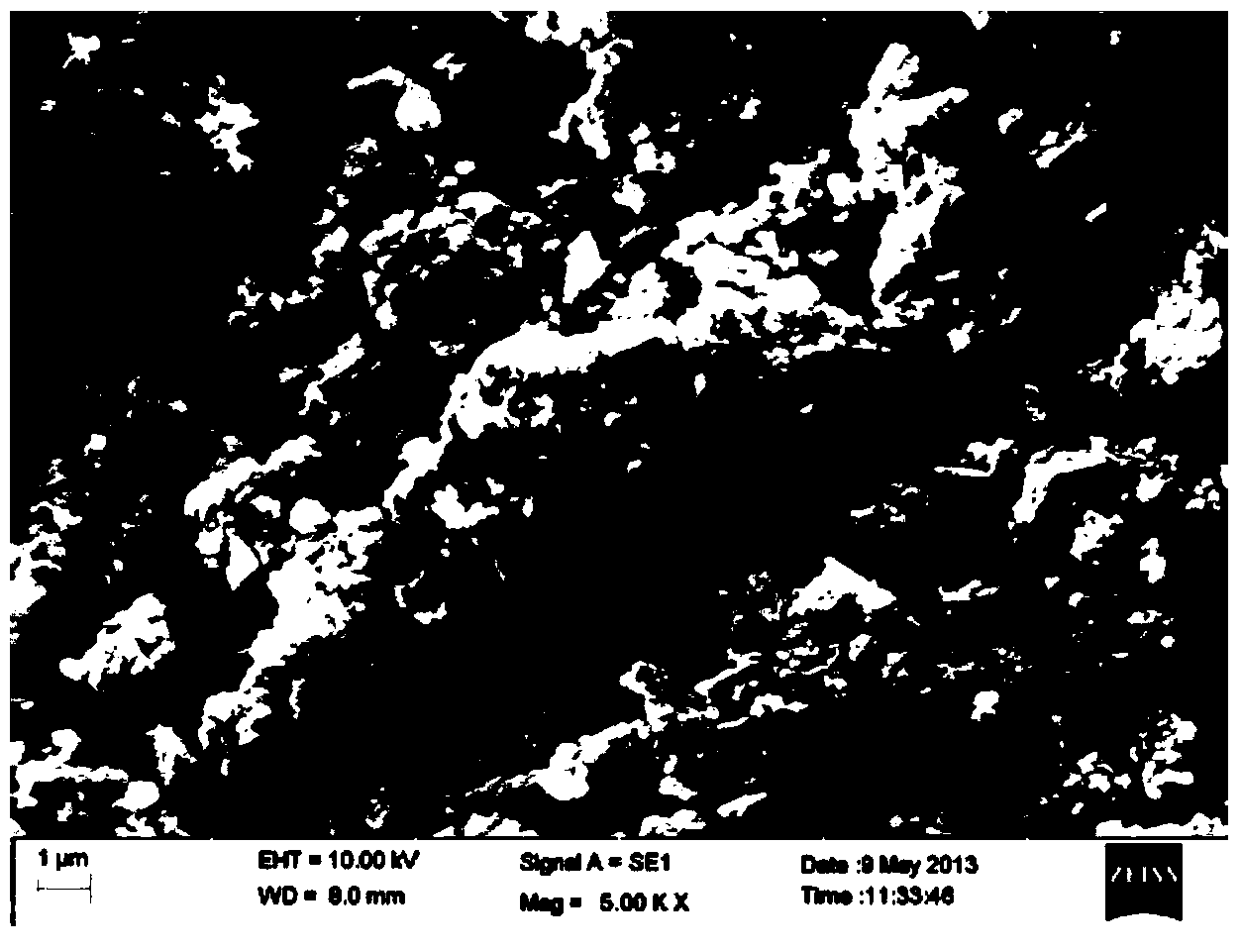

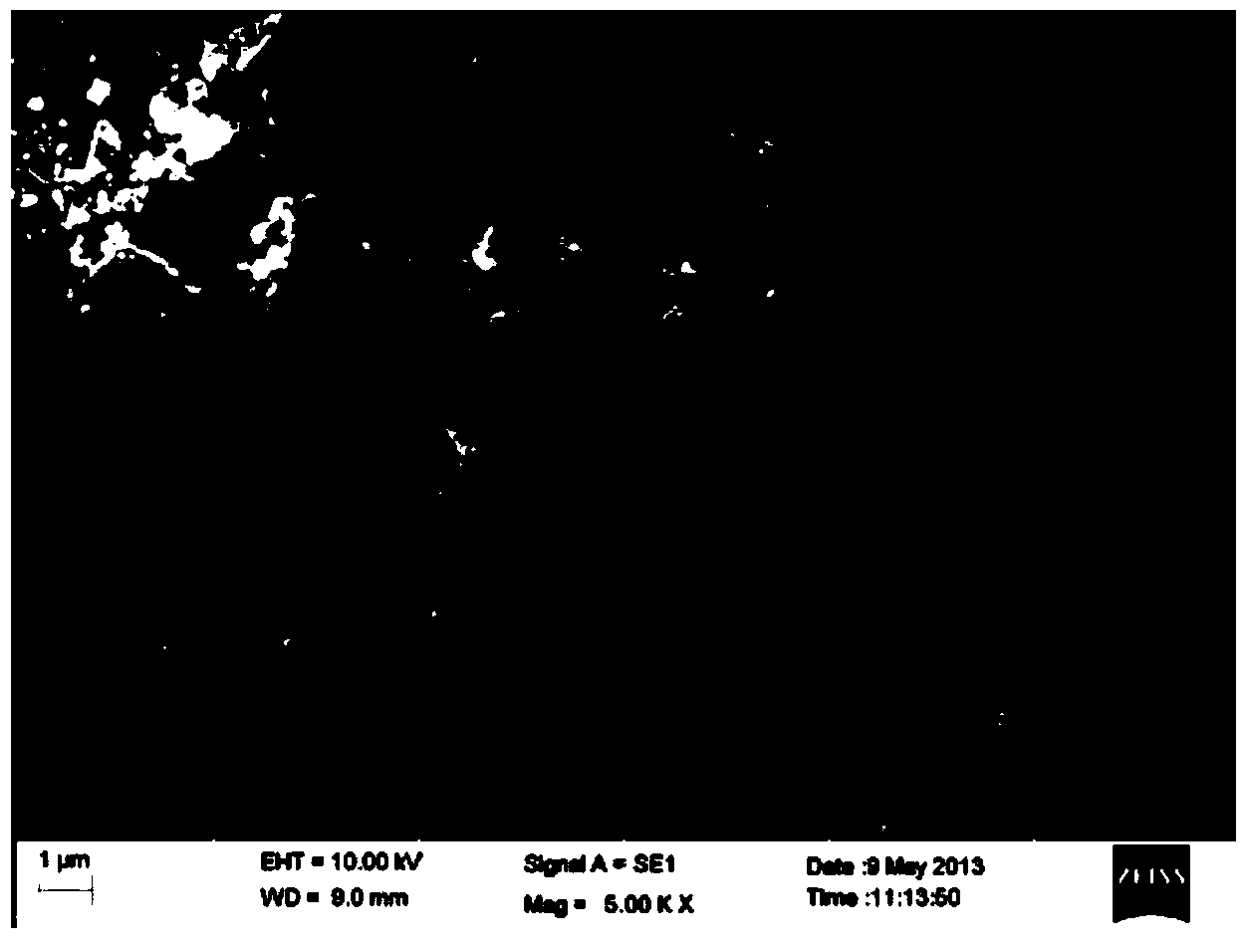

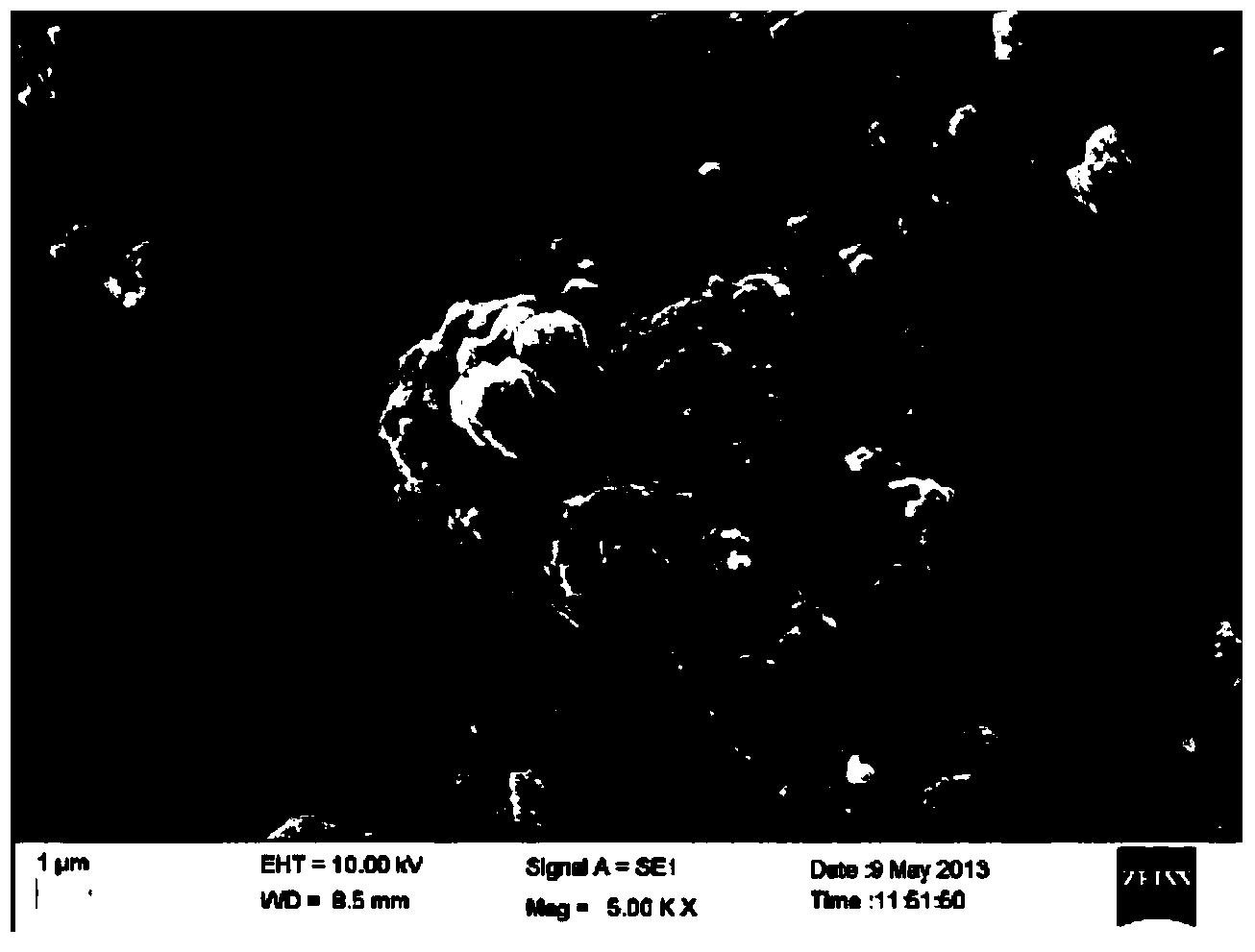

Image

Examples

Embodiment 1

[0024] A method for manufacturing flavor-enhancing and moisturizing cigarette paper, comprising the following steps:

[0025] 1. CaCO for cigarette paper 3 Drying treatment of filler: by mass percentage, CaCO 3 The filler is dried at 105°C until the moisture content is lower than 0.5%;

[0026] 2. Coupling modification process: under the condition of high-speed stirring at 4000 rpm, the dried CaCO 3 Filler and stearic acid coupling agent are mixed, emulsified and modified at 50°C for 30 minutes, and cooled to room temperature after modification; the amount of stearic acid coupling agent is relative to CaCO 3 The mass of filler is 4%; after testing, CaCO 3 The degree of activation of the filler reaches 84%. The coating activation degree of calcium carbonate surface was determined by the characteristic change degree of hydrophobicity after calcium carbonate surface treatment. The specific method is as follows: weigh 2g of sample, place it in a 250mL separating funnel, add 2...

Embodiment 2

[0034] A new method for manufacturing flavor-enhancing and moisturizing cigarette paper and a production process thereof, comprising the following steps:

[0035] 1. CaCO for cigarette paper 3 Drying of fillers, in mass percent, CaCO 3 Dry at 105°C until the moisture content is less than 0.5%.

[0036] 2. Coupling modification process: the dried CaCO 3 Under the action of high-speed agitation (4000 rpm) of the emulsifier, the filler will 3 Stearic acid with a filler mass percentage of 3% was emulsified and modified at 50°C for 30 minutes, and cooled to room temperature after modification;

[0037] 3. Extraction of tobacco extract: Tobacco samples are tobacco leaves; after the tobacco samples are sliced and crushed, use 0.2mol / L NaOH solution to vibrate and extract the above tobacco leaf scraps at 60°C (liquid ratio 10:1). Store in a sealed condition at low temperature (2°C) after extraction;

[0038] 4. Fruit extract: squeeze the apple juice to obtain the juice, based o...

Embodiment 3

[0043] A new method for manufacturing flavor-enhancing and moisturizing cigarette paper and a production process thereof, comprising the following steps:

[0044] 1. CaCO for cigarette paper 3 Drying of fillers, in mass percent, CaCO 3 Dry at 105°C until the moisture content is less than 0.5%.

[0045] 2. Coupling modification process: Coupling modification process: the dried CaCO 3 Under the action of high-speed agitation (4000 rpm) of the emulsifier, the filler will 3 Stearic acid with a filler mass percentage of 5% was emulsified and modified at 50°C for 30 minutes, and cooled to room temperature after modification;

[0046] 3. Extraction of tobacco extract: the tobacco sample is tobacco powder; after the above-mentioned tobacco samples were sliced and crushed, the above-mentioned tobacco leaf fragments were shaken and extracted at 60°C with 0.2mol / L NaOH solution (liquid ratio 10:1 ), sealed and stored at low temperature (2°C) after extraction;

[0047] 4. Fruit ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com