Colorized cigarette paper and preparation method

A cigarette paper and color technology, applied in the direction of paper, papermaking, wrapping paper, etc., can solve the problems of pigments giving cigarettes miscellaneous odor, difficulty in practical application, acceptance by cigarette companies, etc., so as to prevent counterfeiting, increase novelty, and thick aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of Tobacco Extract:

[0039] Tobacco extract is made from flue-cured tobacco, sun-cured red tobacco, oriental tobacco, and Burley tobacco through four processes of extraction, non-enzymatic browning reaction, bioenzymatic browning reaction, and supercritical extraction.

[0040] Preparation of natural extracts:

[0041] Natural extracts are extracts of acorn husk, walnut husk, cocoa husk, sorghum husk.

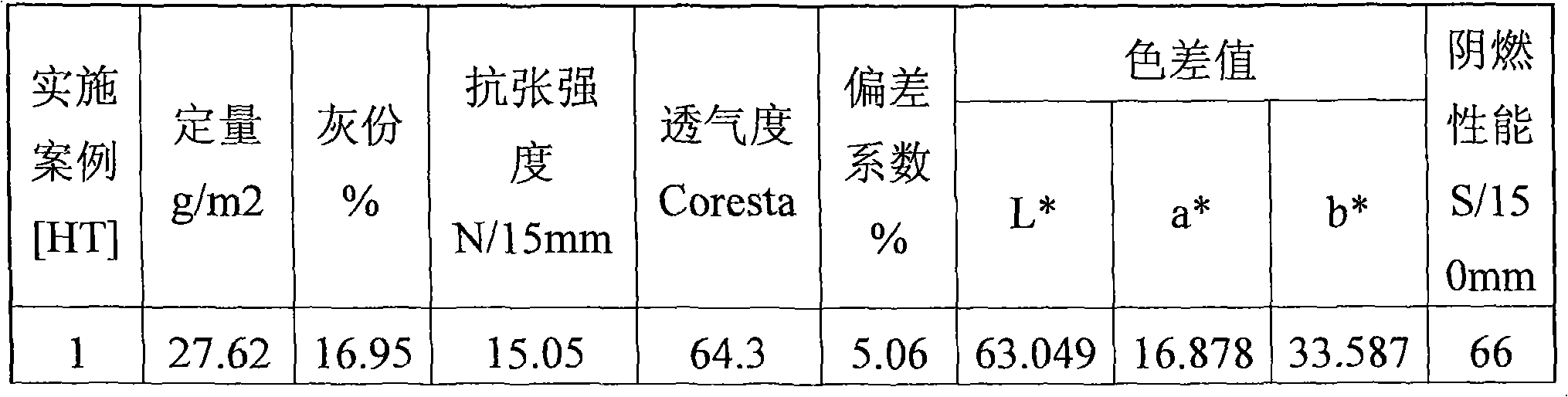

Embodiment 1

[0043] Take 800 kg of wood pulp fiber, add 350 kg of calcium carbonate to the slurry according to the normal production process; add 1.1 m 3 Dissolve in water to prepare a combustion aid solution. Then, after adding 65kg of smoke paste into the prepared combustion enhancer solution, stir well and evenly, and add it on both sides by spraying at the adding place. Cigarette paper is produced according to the conventional papermaking process, and the index of cigarette paper is controlled on the equipment to be quantitative: 28g / m 2 , Breathability: 60 Coresta.

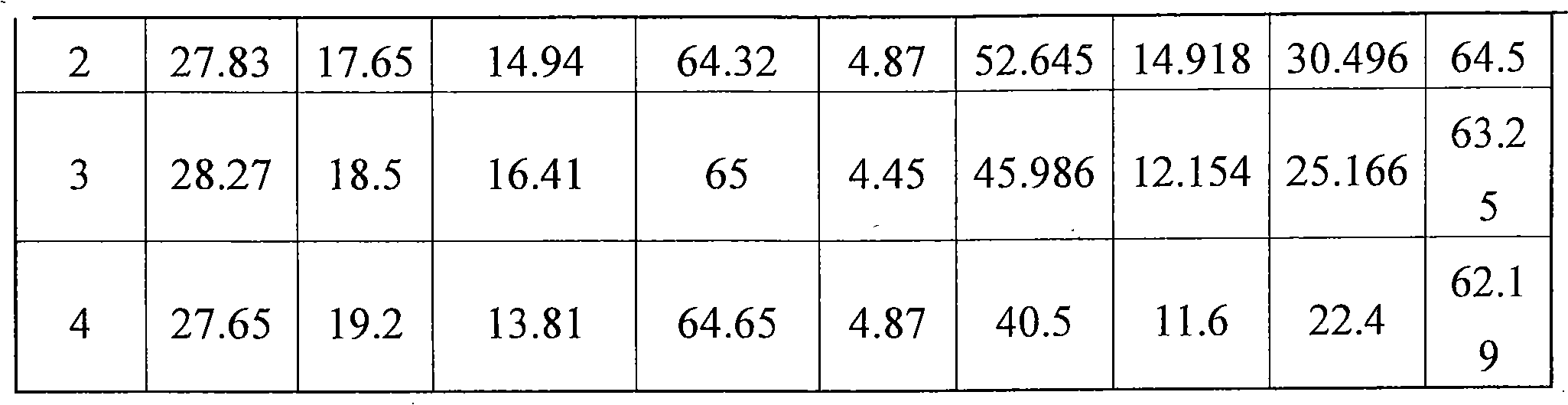

Embodiment 2

[0045] Mix 650 kg of wood pulp fiber with 150 kg of hemp pulp fiber, add 450 kg of calcium carbonate to the slurry according to the normal production process; add 1.1m 3 Dissolve in water to prepare a combustion aid solution. Then add 140kg of smoke cream to the prepared combustion enhancer solution, stir well and evenly, and add it on both sides by spraying at the adding place. Cigarette paper is produced according to the conventional papermaking process, and the index of cigarette paper is controlled on the equipment to be quantitative: 28g / m 2 , Breathability: 60 Coresta.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com