Cigarette for generating smoke through burning or heating

A cigarette and smoke technology, applied in tobacco, cigar manufacturing, smoker's supplies and other directions, can solve the problems of waste of cut tobacco, uneven heating, pollution and deformation of coil paper, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

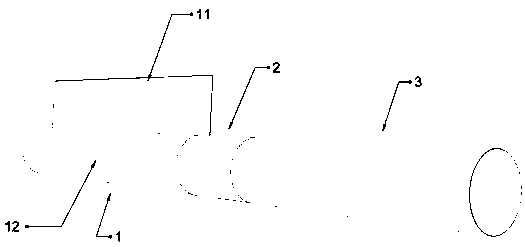

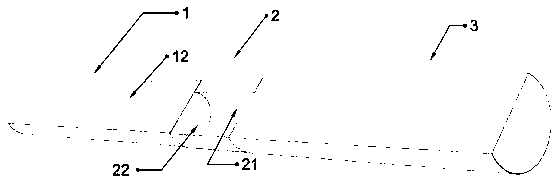

[0042] Such as figure 1 , 2 As shown, a cigarette that generates smoke by burning or heating includes a tobacco section 1, a heat insulation section 2, and a mouthpiece section 3, and the tobacco section 1, heat insulation section 2, and mouthpiece section 3 are connected in sequence; the tobacco section 1 includes The filled cigarette core material 12 and the outer wrapped cigarette paper 11; the heat insulation section 2 is made of porous zeolite that absorbs the essence of tobacco, and the inside is a cavity structure 21, which connects the tobacco section 1 and the mouthpiece section 3; The core material 12 includes: shredded tobacco, tobacco sheet, tobacco additives, and smoking agent, wherein, the mass percentage of the shredded tobacco is 60%, the mass percentage of the tobacco sheet is 20%, and the smoking agent is glycerol, and the mass percentage is 2% ; The cigarette core material 12 is wrapped with a layer of anti-penetration cigarette paper 11.

[0043] When the...

Embodiment 2

[0046] Such as figure 1 , 2 As shown, a cigarette that generates smoke by burning or heating includes a tobacco section 1, a heat insulation section 2, and a mouthpiece section 3, and the tobacco section 1, heat insulation section 2, and mouthpiece section 3 are connected in sequence; the tobacco section 1 includes The filled cigarette core material 12 and the outer wrapped cigarette paper 11; the heat insulation section 2 is made of metal material, and the inside is a cavity structure 21, and the cavity communicates with the tobacco section 1 and the mouthpiece section 3; the cigarette core material 12 includes: Shredded tobacco, tobacco sheet, tobacco additives, smoking agent, wherein, the mass percentage of said shredded tobacco is 76%, the mass percentage of tobacco sheet is 10%, the smoking agent is propylene glycol, and the mass percentage is 8%; the outer wrapping of cigarette core material 12 There is a layer of impermeable cigarette paper.

[0047] When the cigarett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com