Non-combustion type low temperature cigarette product based on phase change temperature-controlled fuel assembly and preparation method of aerosol generating section

A technology for aerosol generation and fuel assembly, which is used in tobacco, cigar manufacturing, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

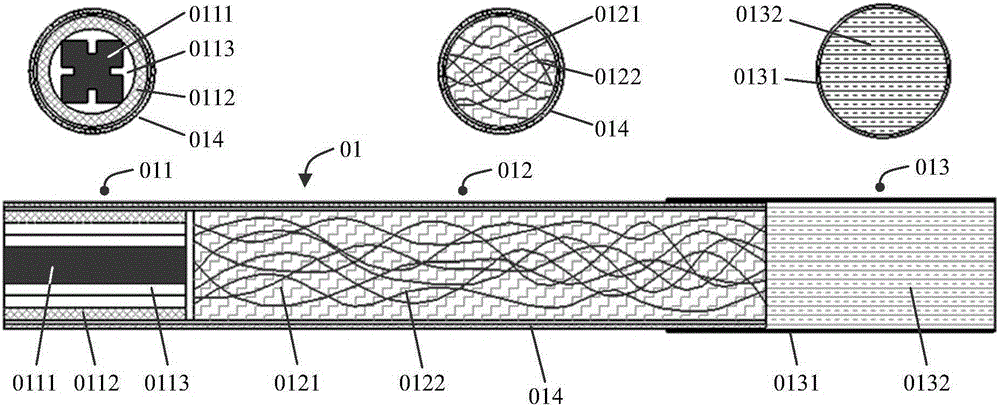

[0112] like figure 1 As shown, a non-combustible low-temperature cigarette product 01 composed of a phase-change temperature-controlled fuel assembly and high thermal conductivity MPCF carbon fiber filaments consists of a phase-change temperature-controlled fuel assembly section 011 and an aerosol generating section 012 that forms smoke and The filter section 013 is composed of the phase-change temperature-controlled fuel assembly section 011 and the aerosol generating section 012 that forms smoke, and is wrapped adjacently by the non-combustible low-temperature cigarette using nano-silica airgel heat-insulating cigarette paper 014. The smoke-forming aerosol generating section 012 and the filter section 013 are connected and wrapped with tipping paper to form the phase-change temperature-controlled fuel assembly section 011 and the smoke-forming aerosol section along the mainstream smoke flow direction. The integrated structure of the generating section 012 and the filter sect...

Embodiment 2

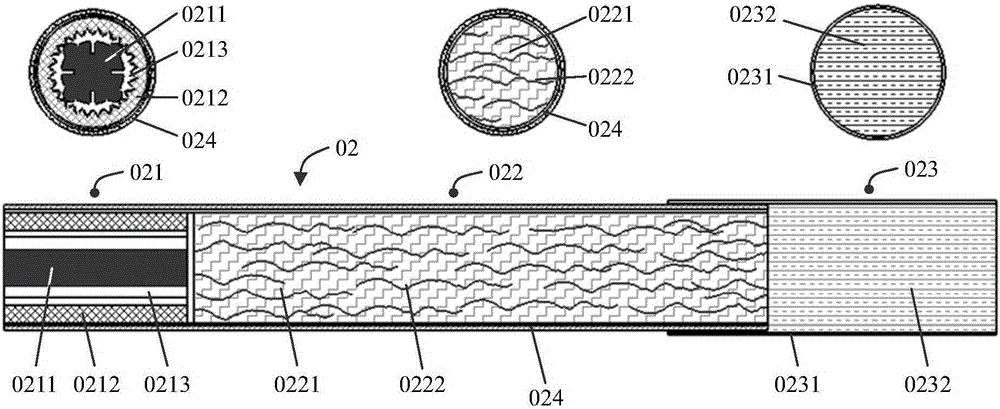

[0124] like figure 2 As shown, another non-combustible low-temperature cigarette product 02 composed of a phase-change temperature-controlled fuel assembly and high-thermal conductivity MPCF short carbon fibers consists of a phase-change temperature-controlled fuel assembly section 021 and an aerosol generating section 022 that forms smoke and filter section 023, wherein, the phase-change temperature-controlled fuel assembly section 021 and the aerosol generating section 022 forming smoke are adjacently wrapped by nano-silica airgel heat-insulating cigarette paper 024 for non-combustible low-temperature cigarettes The package, the aerosol generating section 022 forming smoke and the filter section 023 are connected by tipping paper to wrap the package, forming along the flow direction of the mainstream smoke, followed by the phase-change temperature-controlled fuel assembly section 021, and the gas forming section 023 forming smoke. The integrated structure of the sol generat...

Embodiment 3

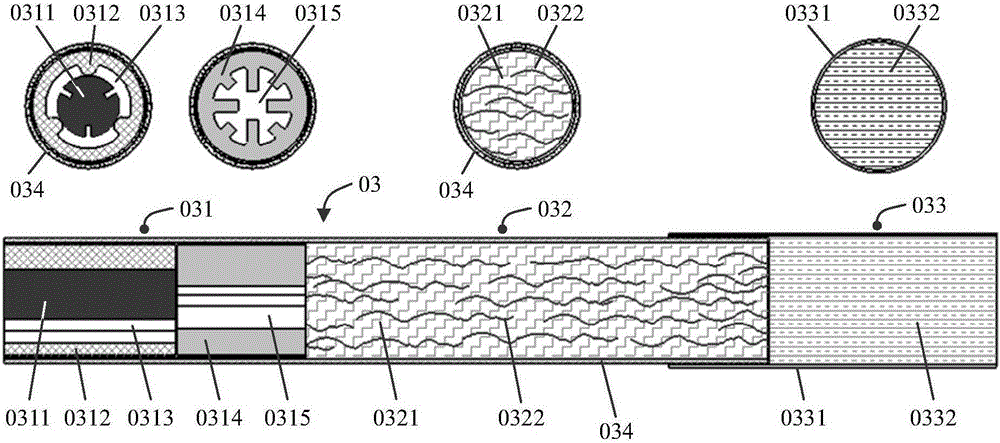

[0135] like image 3 As shown, a non-combustible low-temperature cigarette product 03 composed of a phase-change temperature-controlling fuel assembly, a temperature-controlling tube, and high-thermal conductivity MPCF short carbon fibers is composed of a phase-change temperature-controlling fuel assembly segment 031 and an aerosol that forms smoke The generation section 032 and the filter section 033 are composed of the phase-change temperature-controlled fuel assembly section 031 and the aerosol generation section 032 that forms smoke, and the non-combustible low-temperature cigarette uses nano-silica airgel heat-insulating cigarette paper 034 Connect and wrap the package, the aerosol generating section 032 and the filter section 033 that form the smoke are connected and wrapped with the tipping paper, forming along the flow direction of the mainstream smoke, followed by the phase change temperature control type fuel assembly section 031, forming The integrated structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com