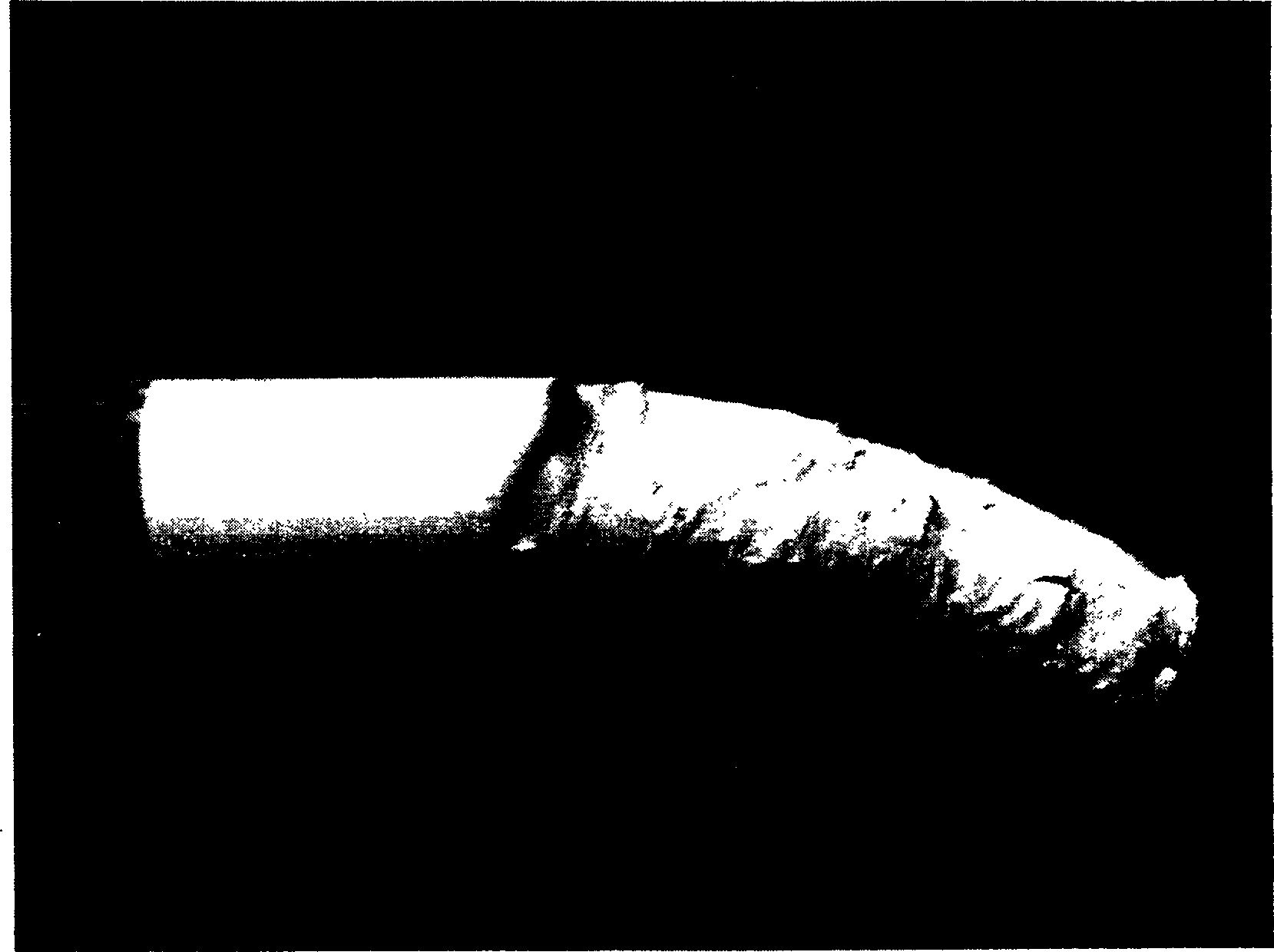

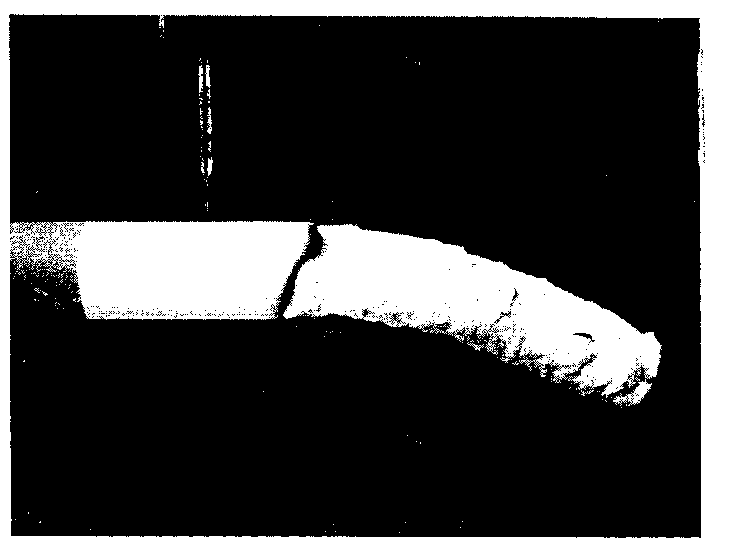

Functional cigarette paper

A cigarette paper, functional technology, applied in papermaking, textile and papermaking, fiber raw material processing and other directions, can solve the problems of complex production process, unsuitable high-speed operation of cigarette units, cigarette fly ash, etc., and achieve good social and economic benefits. , very promising market development, the effect of improving the ash-packing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 600 kilograms of wood pulp, add 72 kilograms of silicon compound, 120 kilograms of light calcium carbonate, 3 kilograms of nano aluminum oxide, and 4 kilograms of sodium alginate. Prepare 12% potassium lithium malate, 16% potassium sodium malate, 8% potassium carbonate and 4% xylitol aqueous solution at the place where the combustion enhancer is added by coating on one side. The cigarette paper is produced according to the conventional papermaking process, and the cigarette paper indicators are controlled on the equipment: basis weight: 34.0g / m2, air permeability: 60 Costa.

Embodiment 2

[0022] Take 600 kilograms of wood pulp, add 130 kilograms of light calcium carbonate, 6 kilograms of nano aluminum oxide, and prepare 12% potassium lithium malate, 20% potassium sodium malate, and 10% potassium carbonate aqueous solution at the place where the combustion enhancer is added. The coating method is single-sided addition. The cigarette paper is produced according to the conventional papermaking process, and the cigarette paper indicators are controlled on the equipment: basis weight: 28.0g / m2; air permeability: 60 Costa.

Embodiment 3

[0024] Take 600 kilograms of wood pulp, add 92 kilograms of silicon-containing mixture, 100 kilograms of light calcium carbonate, 2 kilograms of nano aluminum oxide, and prepare 16% potassium lithium malate, 10% potassium sodium malate, and 10% potassium carbonate aqueous solution Coating method is used for single-side addition at the place where the oxidizer is added. The cigarette paper is produced according to the conventional papermaking process, and the cigarette paper indicators are controlled on the equipment: basis weight: 34.09 / m2; air permeability: 60 Costa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com