Cigar tobacco paper and a method for packaging the same

a tobacco paper and cigar technology, applied in the field of cigar tobacco paper and system, can solve the problems of difficult rollover of tobacco filler, laborious and time-consuming wrapping and/or creating a cigarette, and limitations regarding the types of cigar wrappers that may be used, and the time and effort that a user may have to exert in order to achieve the effect of distributing the product,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

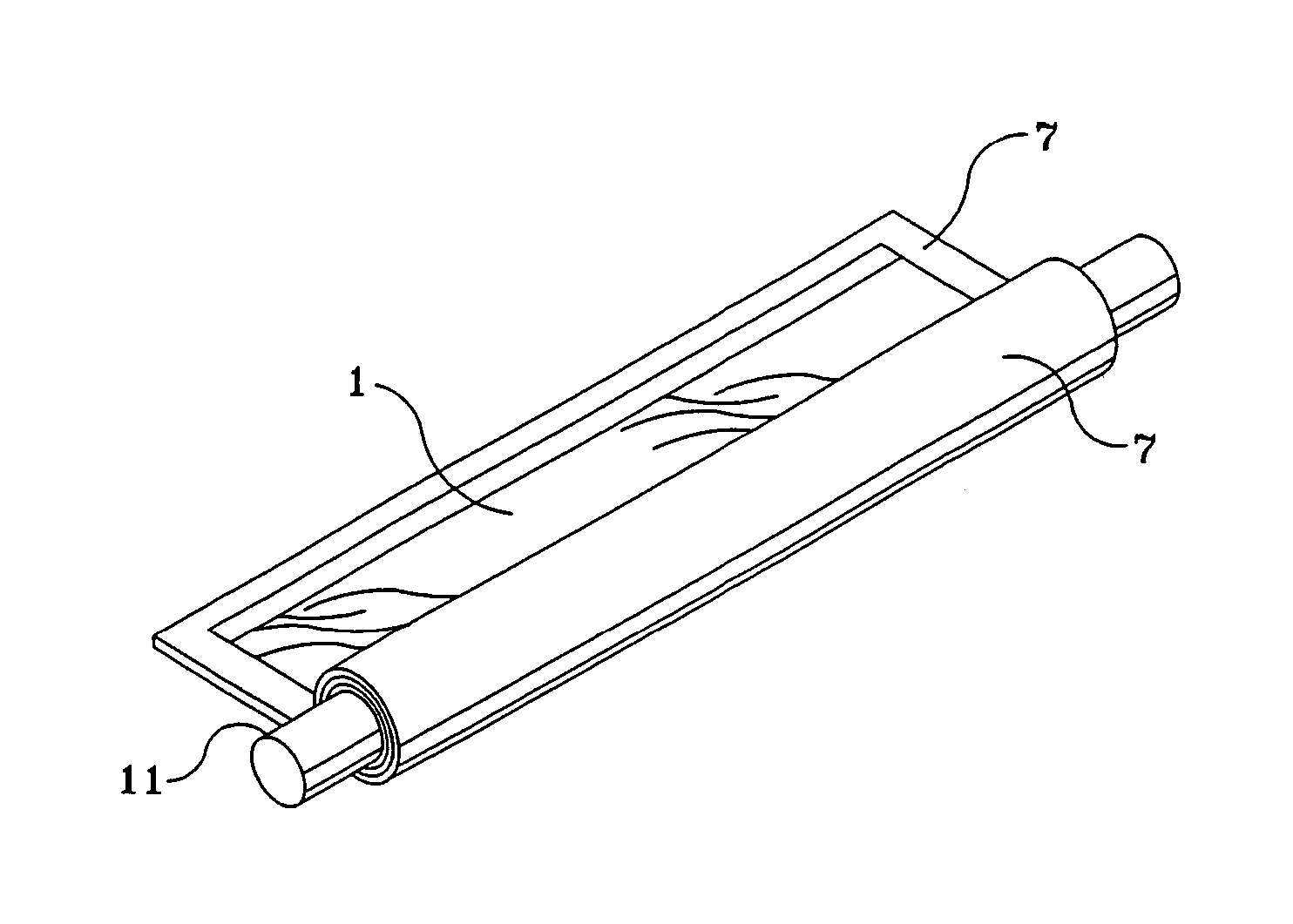

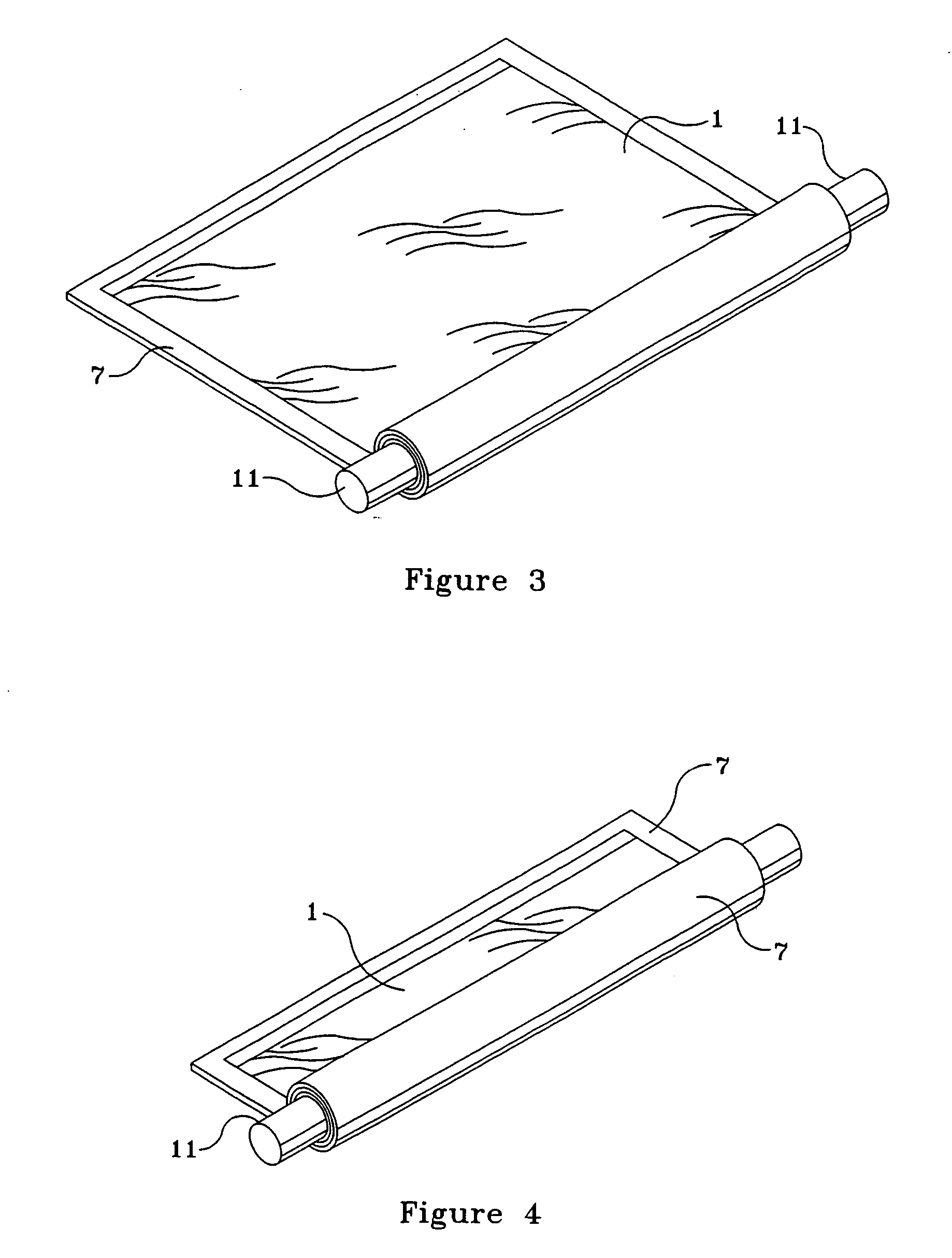

[0072] Turning now to the drawings wherein elements are identified by numbers and like elements are identified by like numbers throughout the 6 figures, the invention is depicted in FIG. 1 that shows a cigar tobacco paper and a method for packaging the same. As shown in FIG. 1, the cigar tobacco paper 1 is wrapped into a plurality of layers 3 to be formed into a cylindrical shape. As illustrated in the cross sectional perspective view of FIG. 1, a plurality of layers may be formed when the cigar tobacco paper 1 is encased about the enveloping means 7.

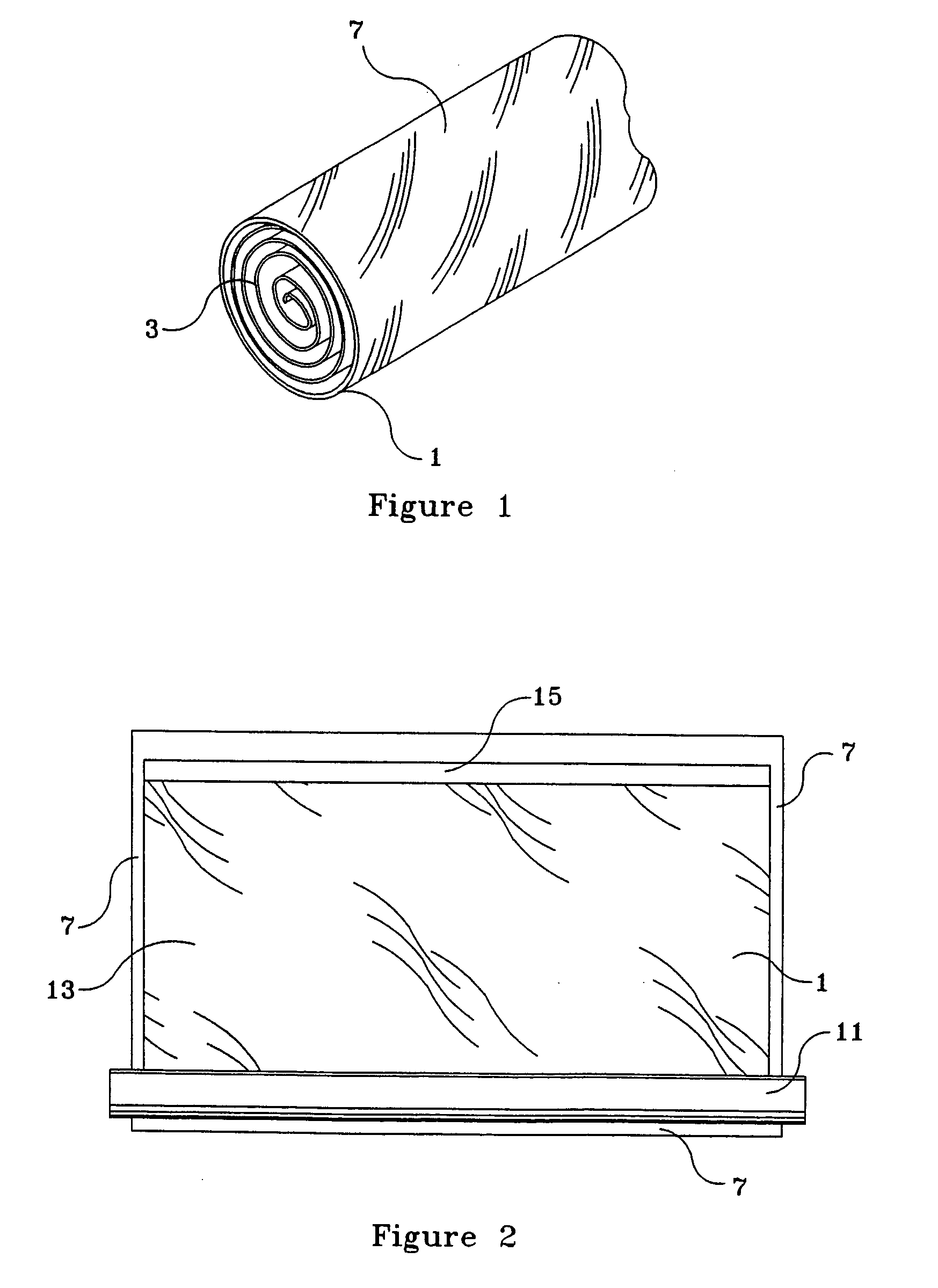

[0073]FIG. 2 illustrates a top view of the cigar tobacco paper 1 and cylindrical object 11 before the cigar tobacco paper 1 rolled into a cylindrical shape. To enable the rolling of the cigar tobacco paper 1 into a cylindrical shape for easy use by a user (not shown), an enveloping means 7 and a cylindrical object 11 may be used. The cylindrical object 11 may be any object holding a cylindrical shape. However, the cylindrical object 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| cylindrical shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com