Multi-time two-sided gas blowing type recycling machine for tobacco shred of waste cigarette

A technology for waste cigarettes and air blowing, which is applied in the fields of tobacco, paper cigarette manufacturing, and application, can solve the problems of unsatisfactory recovery effect, limited number of cigarettes, low work efficiency, etc., and achieves great promotion and application value and high recovery rate of cut tobacco. , good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

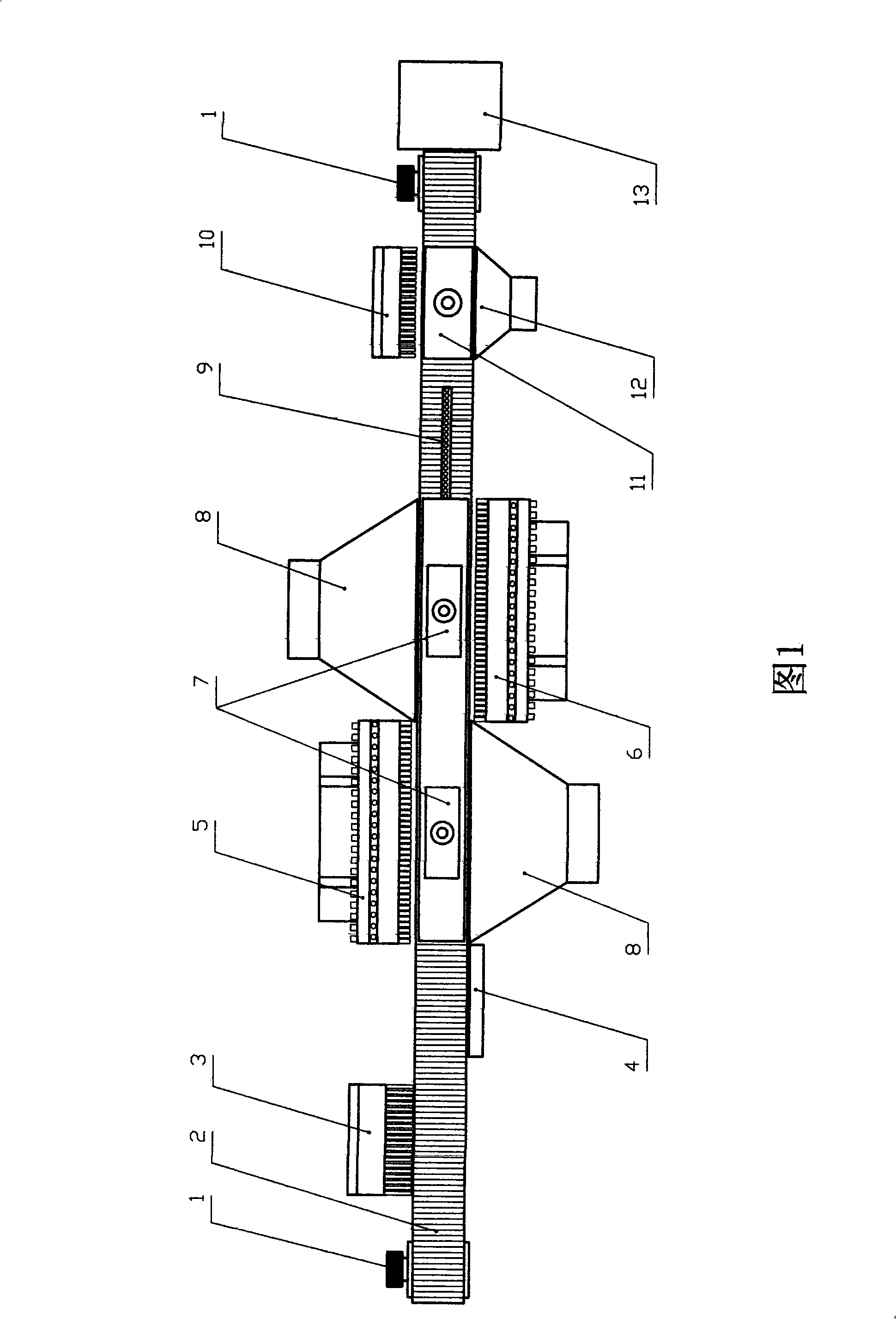

[0008] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0009] 2 synchronous pulleys (1) drive the groove conveyor belt (2) to run, and each groove can put a waste cigarette. The cigarette ejector mechanism (3) is placed on the left side of the grooved conveyor belt (2), and pushes 20 waste cigarettes into corresponding grooves of the grooved conveyor belt (2) each time. The filter tip detector (4) is placed on the right side of the groove conveyor belt (2), measures the filter tip direction, quantity and specific position of 20 waste cigarettes, and sends a detection signal to the PLC in time. The left blowing nozzle group (5) and the right blowing nozzle group (6) each containing 40 blowing nozzles are respectively placed on the left and right sides of the groove conveyor belt (2), and the smoke pressing plate mechanism ( 7) Placed above the groove conveyor belt (2) corresponding to the left blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com