Method and apparatus for recovering inferior cigarettes and tobacco by gas separation

A gas separation and secondary smoke technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low tobacco recovery rate, increase cost, and affect the quality of tobacco, and achieve the effect of compact equipment structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

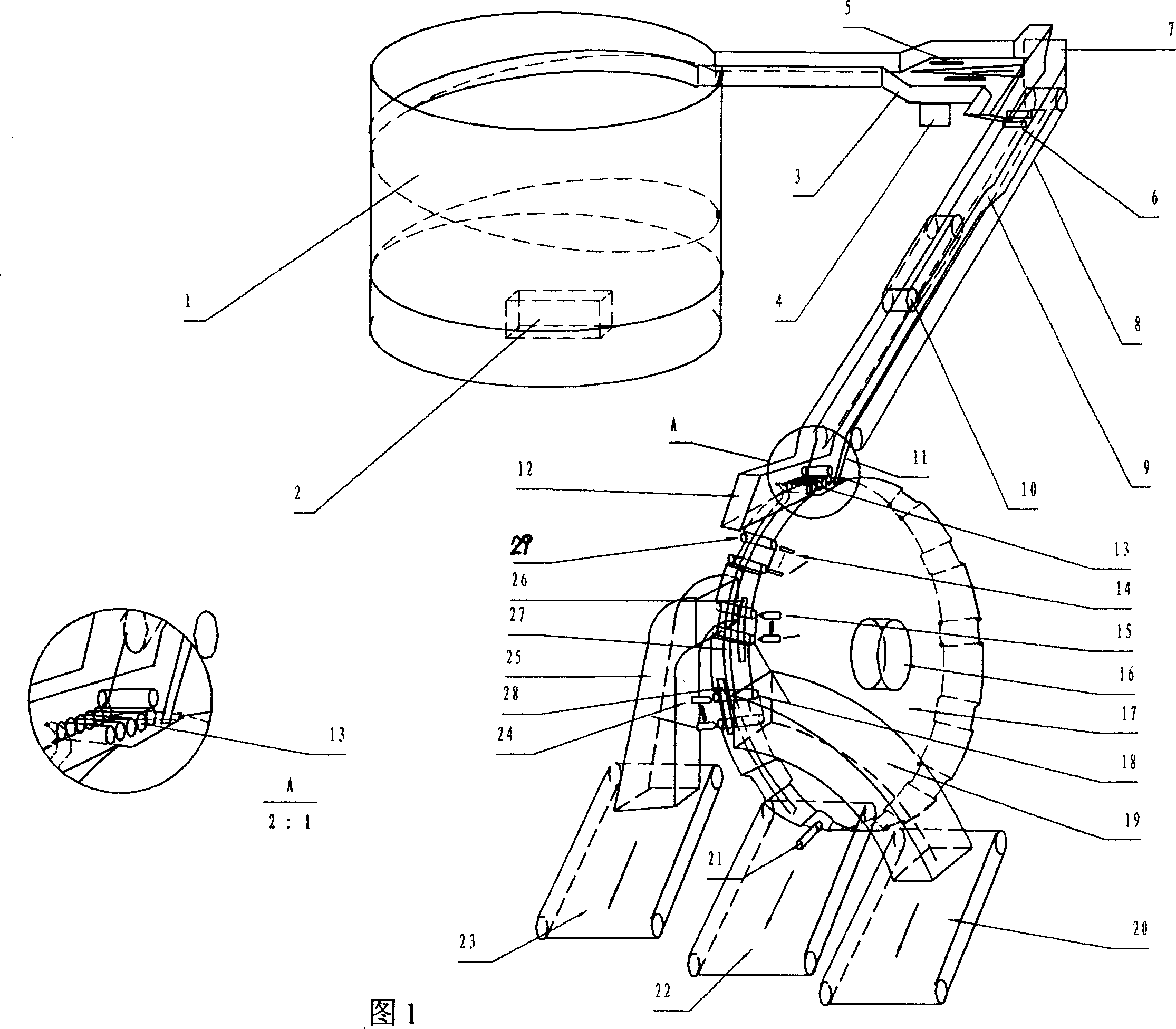

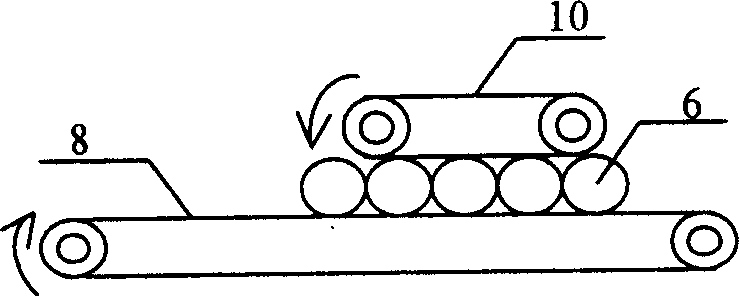

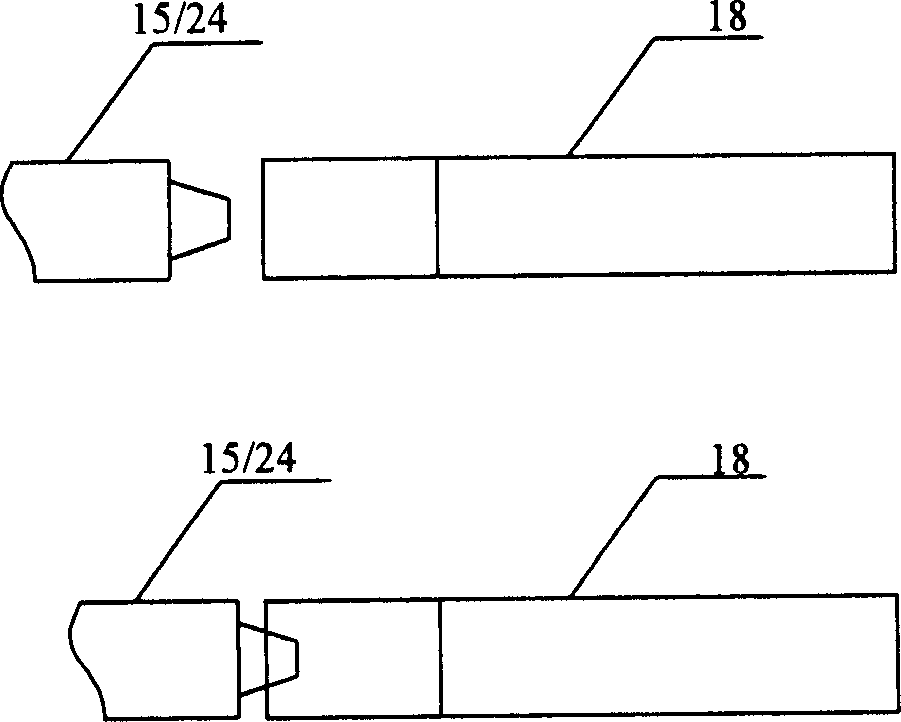

[0019] The gas separation method and device for reclaiming residual and secondary cigarette shreds of the present invention are as shown in Figure 1: the feeding device is driven by a vibrating motor or a vibrating electromagnet 2, and a spiral vibrating groove 1 with a special angle is used to eliminate messy The remnant and second-order cigarettes are arranged neatly and move in a straight line, as shown in Figure 5, continuously and orderly vibrate into the linear vibrating groove 3, and under the vibration of the linear vibrating groove, the rectilinearly moving defective cigarettes 5 reach the linear vibrating groove The end falls into the hopper, falls horizontally on the conveyor belt 8, and is taken away by it to realize the lateral movement of the cigarettes for feeding. The end plate 7 is used to prevent the cigarettes from scattering or changing direction. Movement, but uneven, by the side finishing guard plate 9 gradually close to.

[0020] The shaping device 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com