Patents

Literature

34results about How to "Prevent change of direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

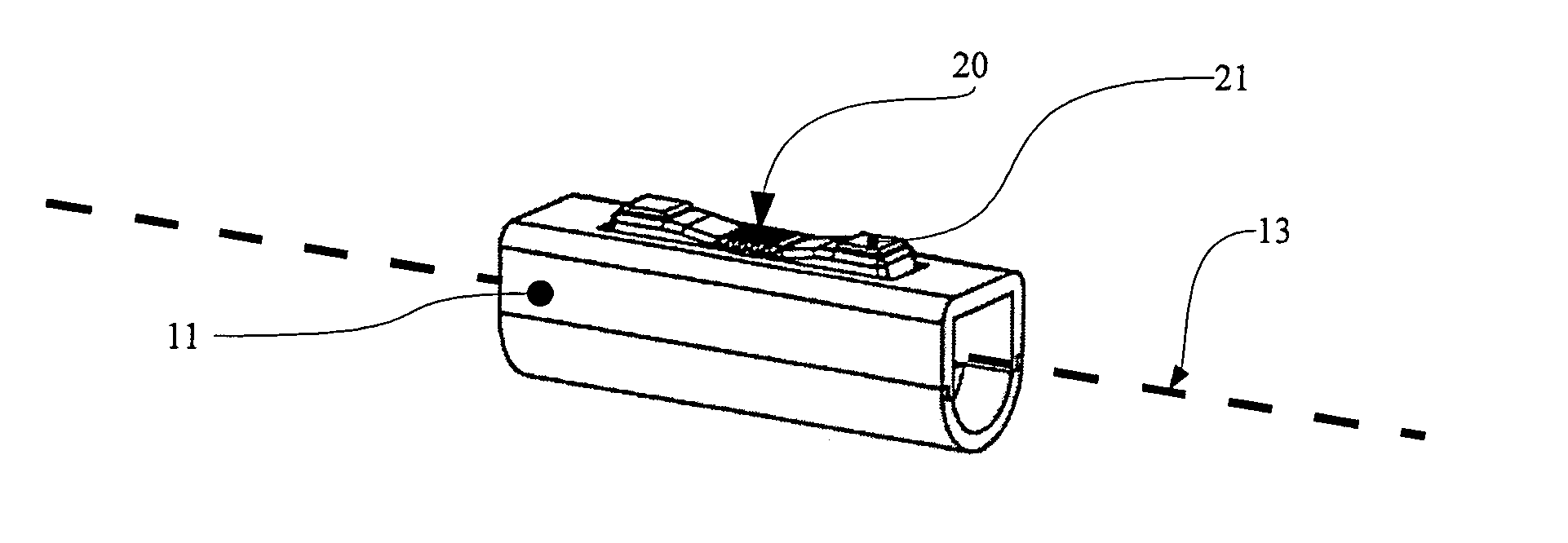

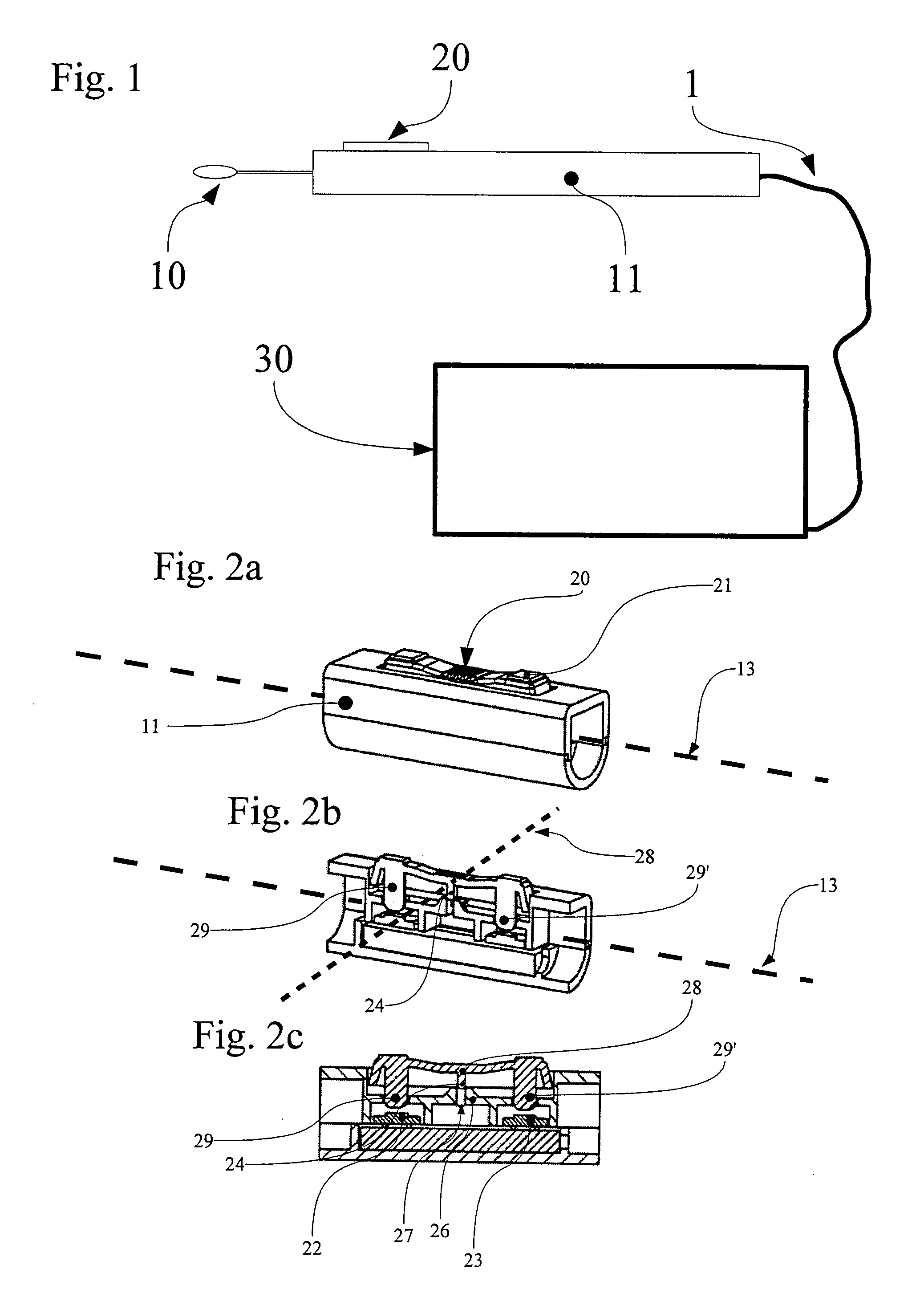

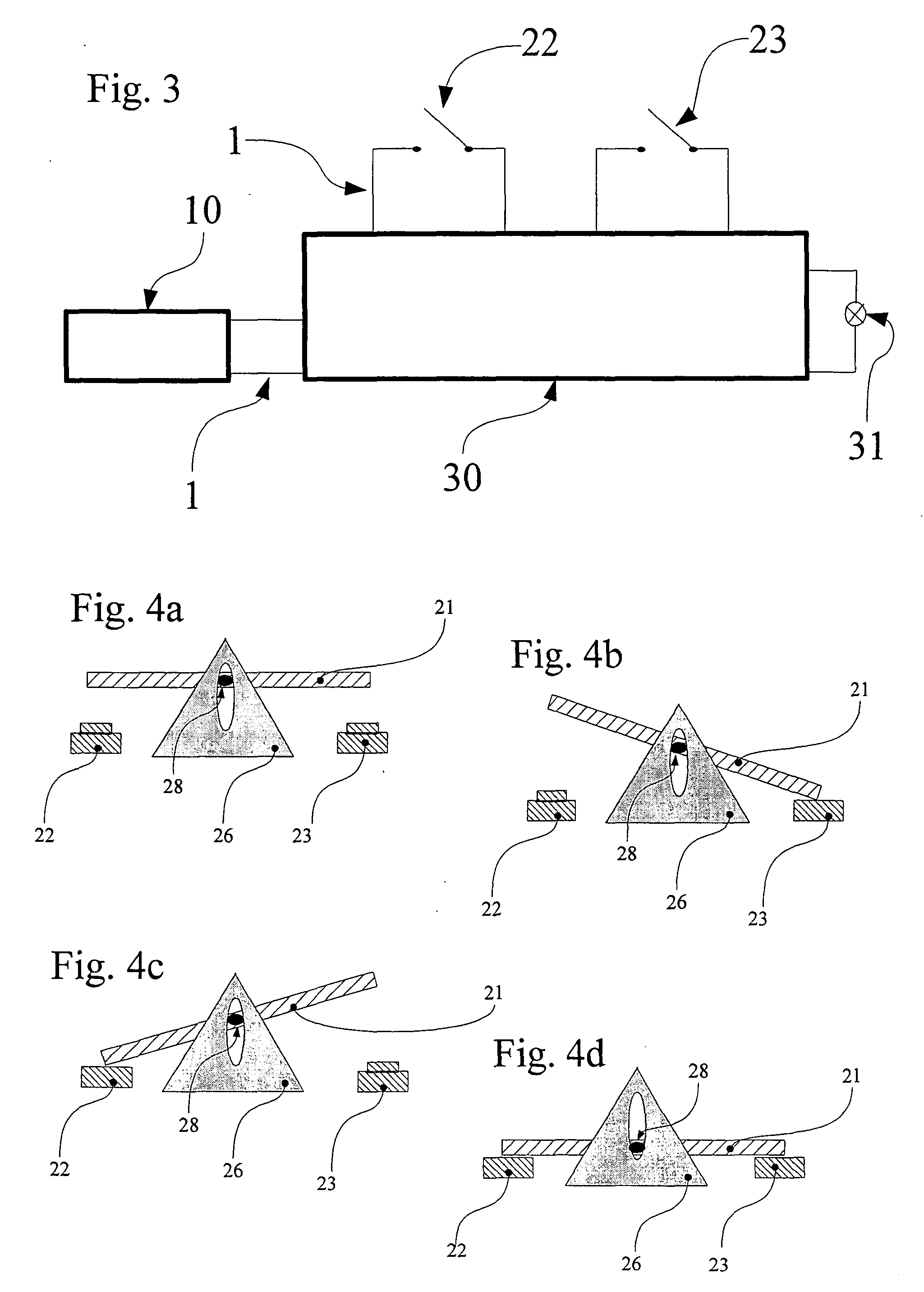

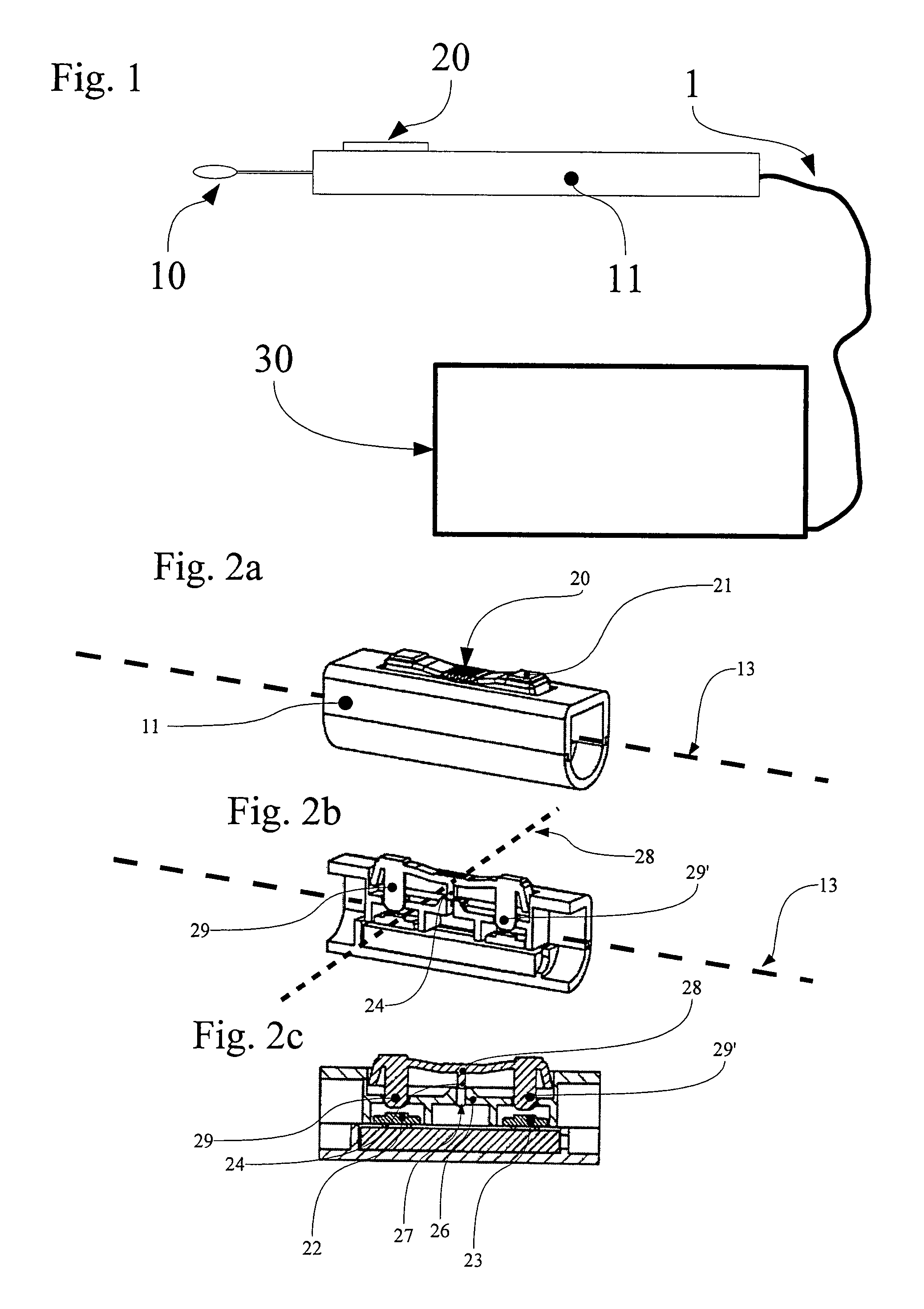

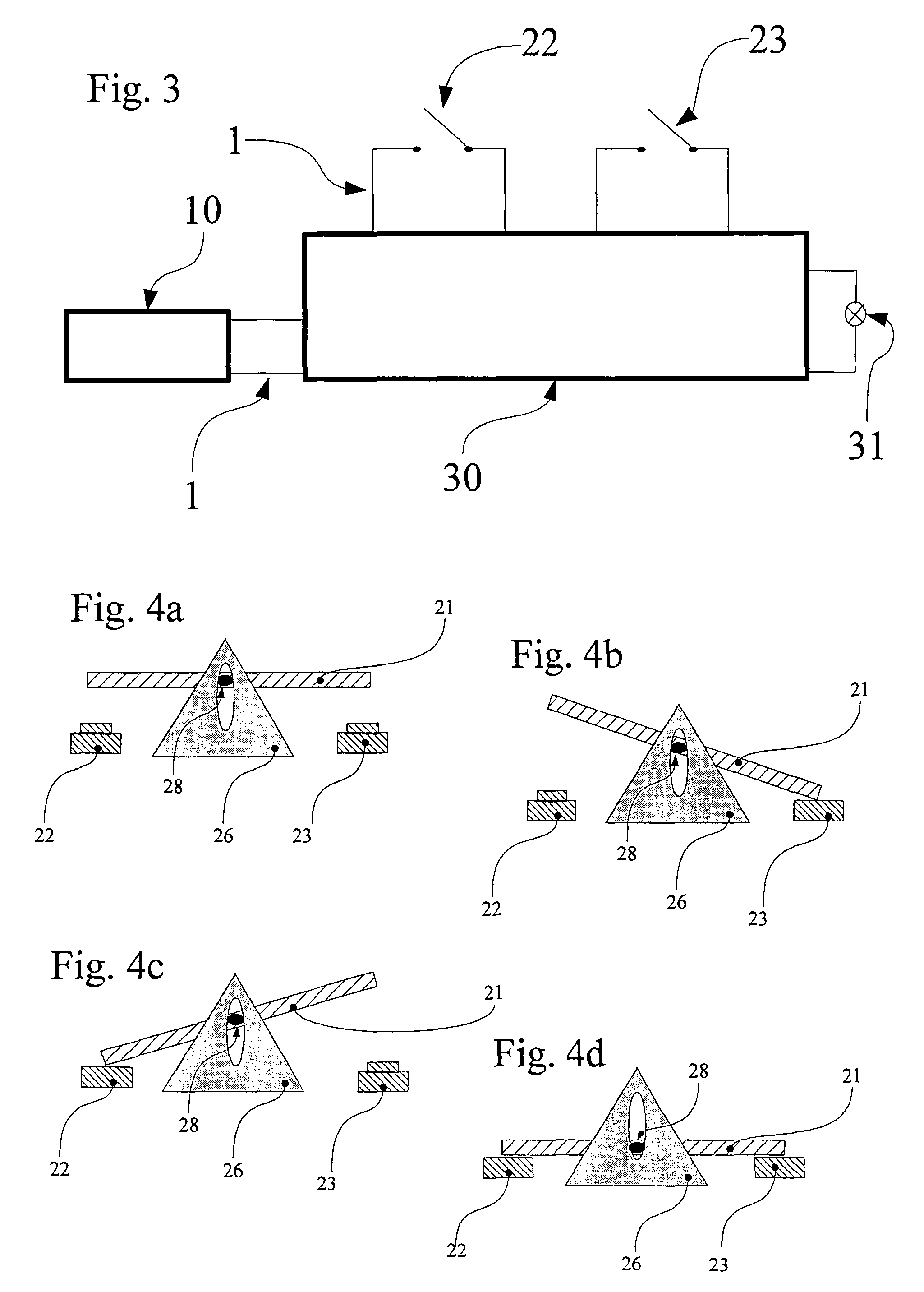

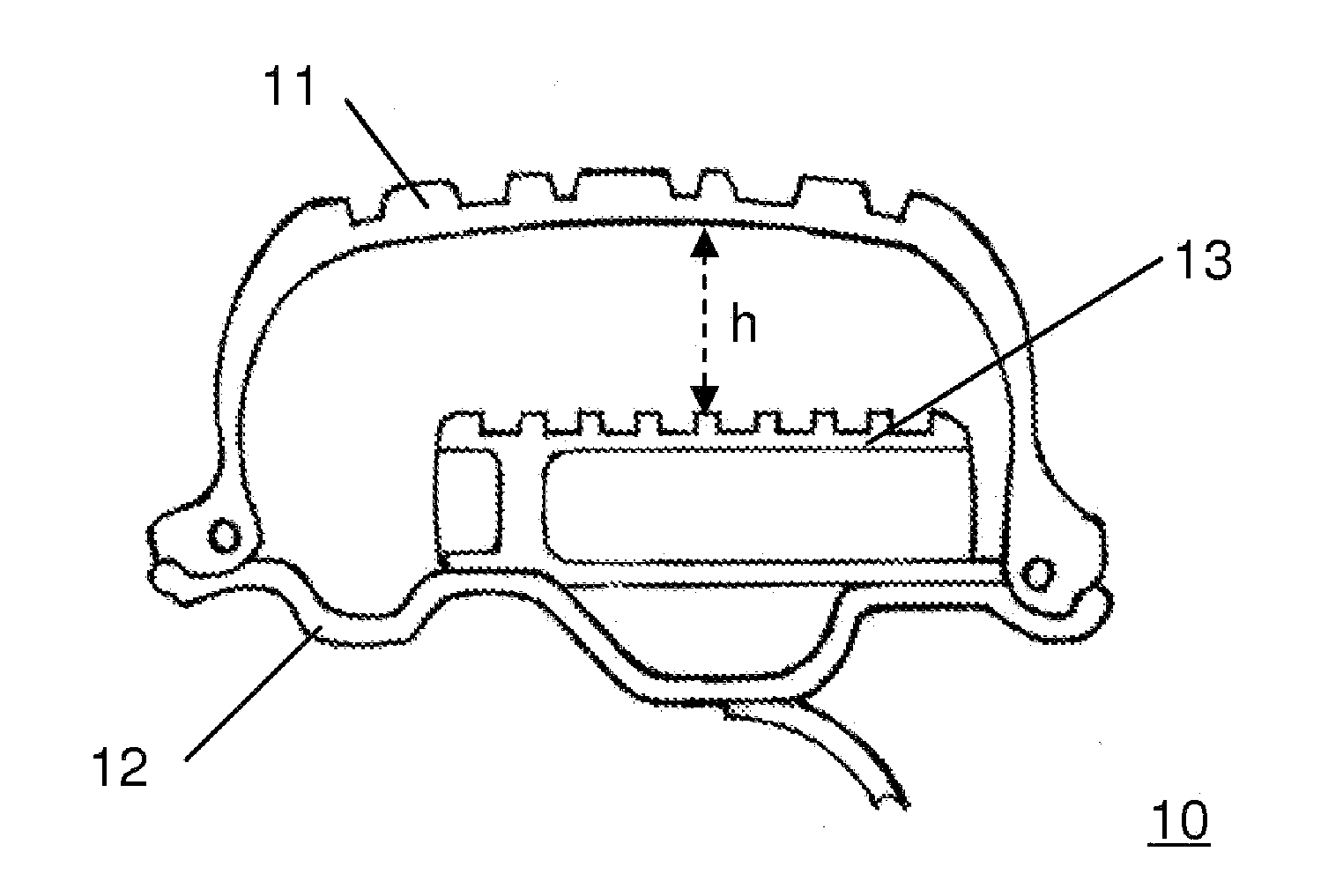

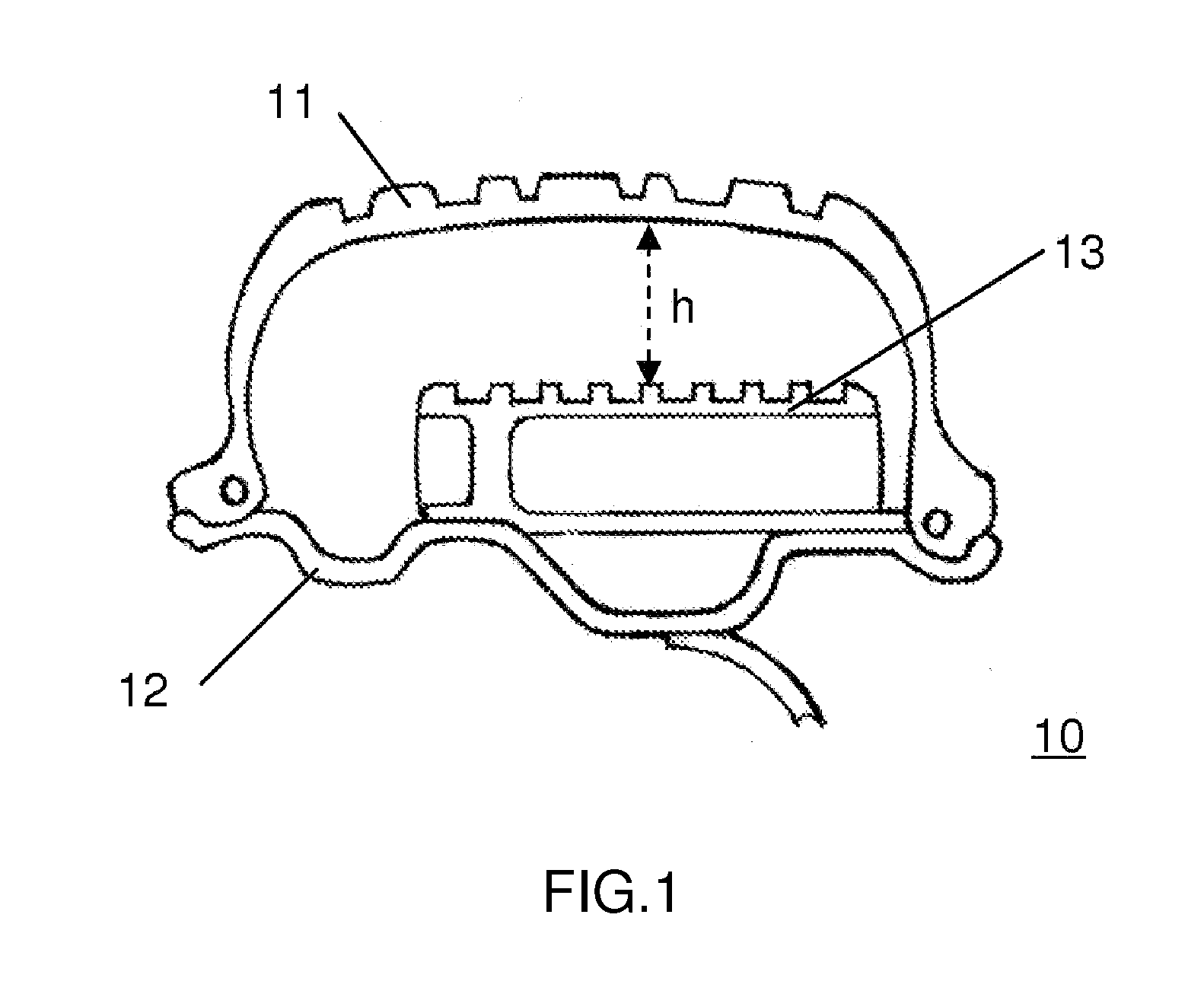

Four-position rocker switch for electrosurgical handpiece

ActiveUS20090076504A1Easy to operateQuality improvementSurgical instrument detailsElectric switchesEngineeringRocker arm

A surgical apparatus includes an actuation unit disposed on a handle and a control unit providing at least three modes for controlling the electrical instrument. The actuation unit contains a switching rocker with an operating element, which is rotatable about a rocker axis that can be shifted perpendicular to the surface of the handle, so that starting from an initial position a first or second function position can be reached by forwards or backwards rotation about the rocker axis, and a third function position can be reached by pressing the operating element inward, two sensors being disposed on the operating element, one on the left and the other on the right side of the rocker axis, in such a way that by means of the sensors the function position selected by means of the switching rocker can be determined by the control unit.

Owner:ERBE ELEKTROMEDIZIN GMBH

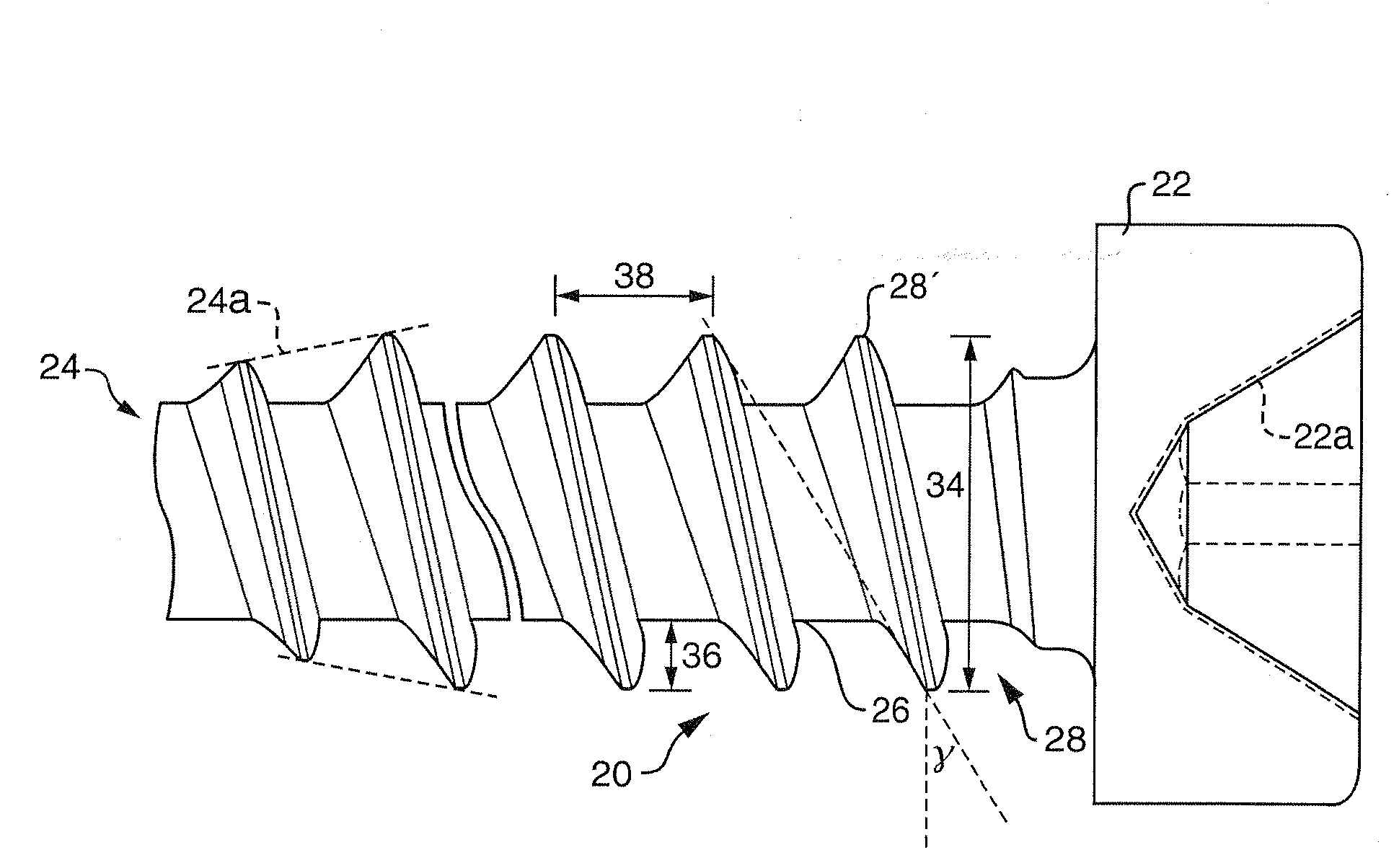

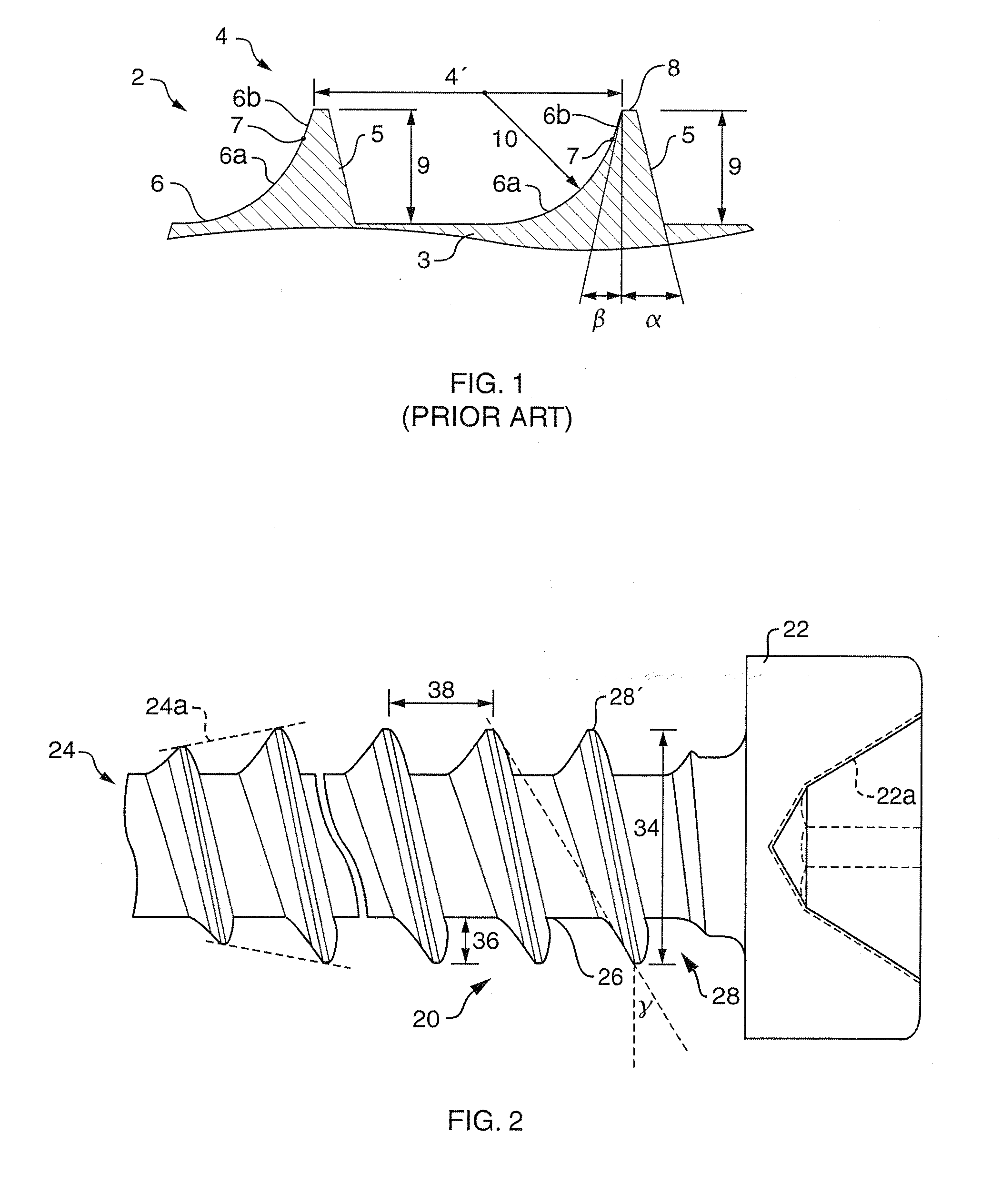

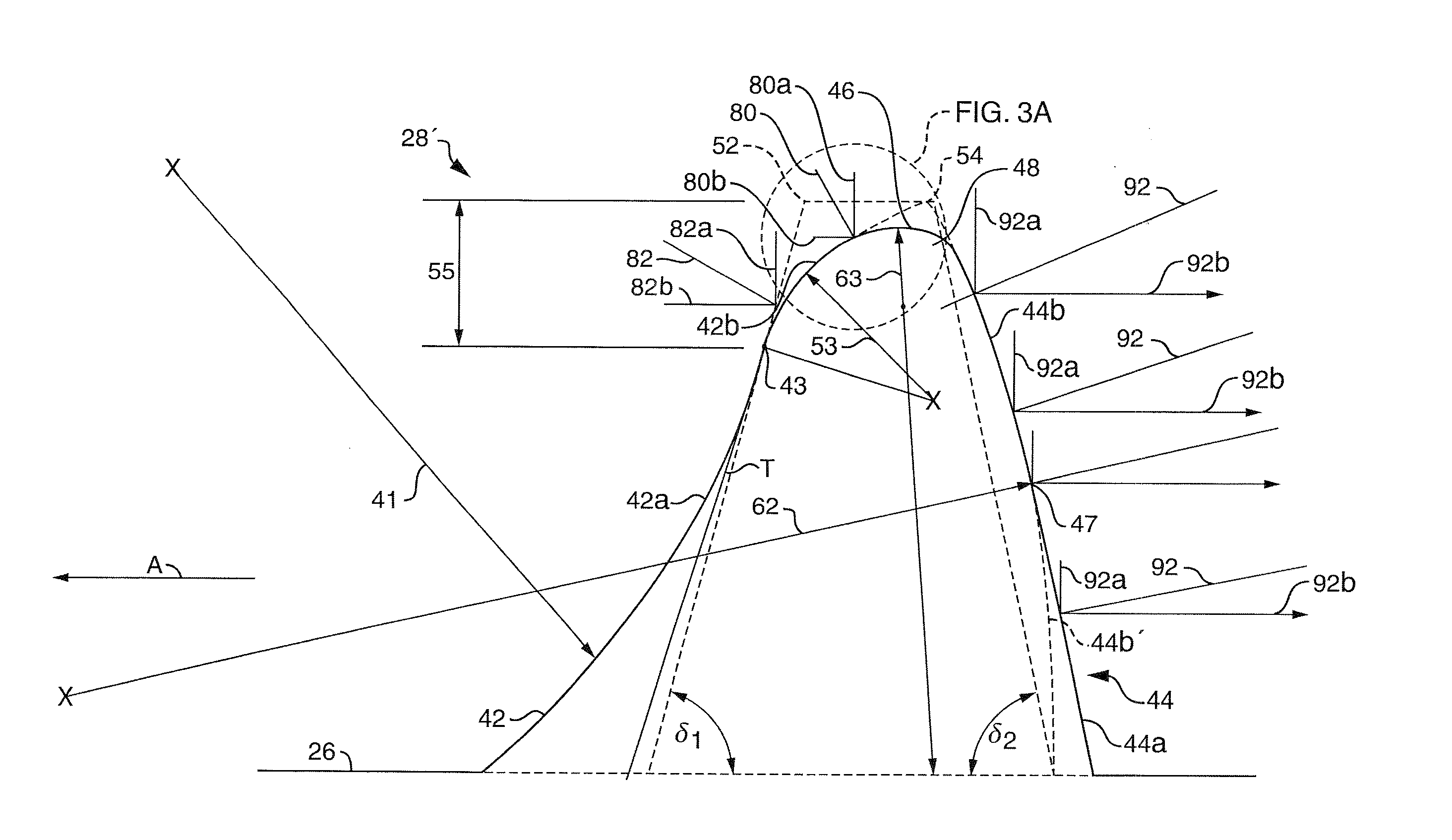

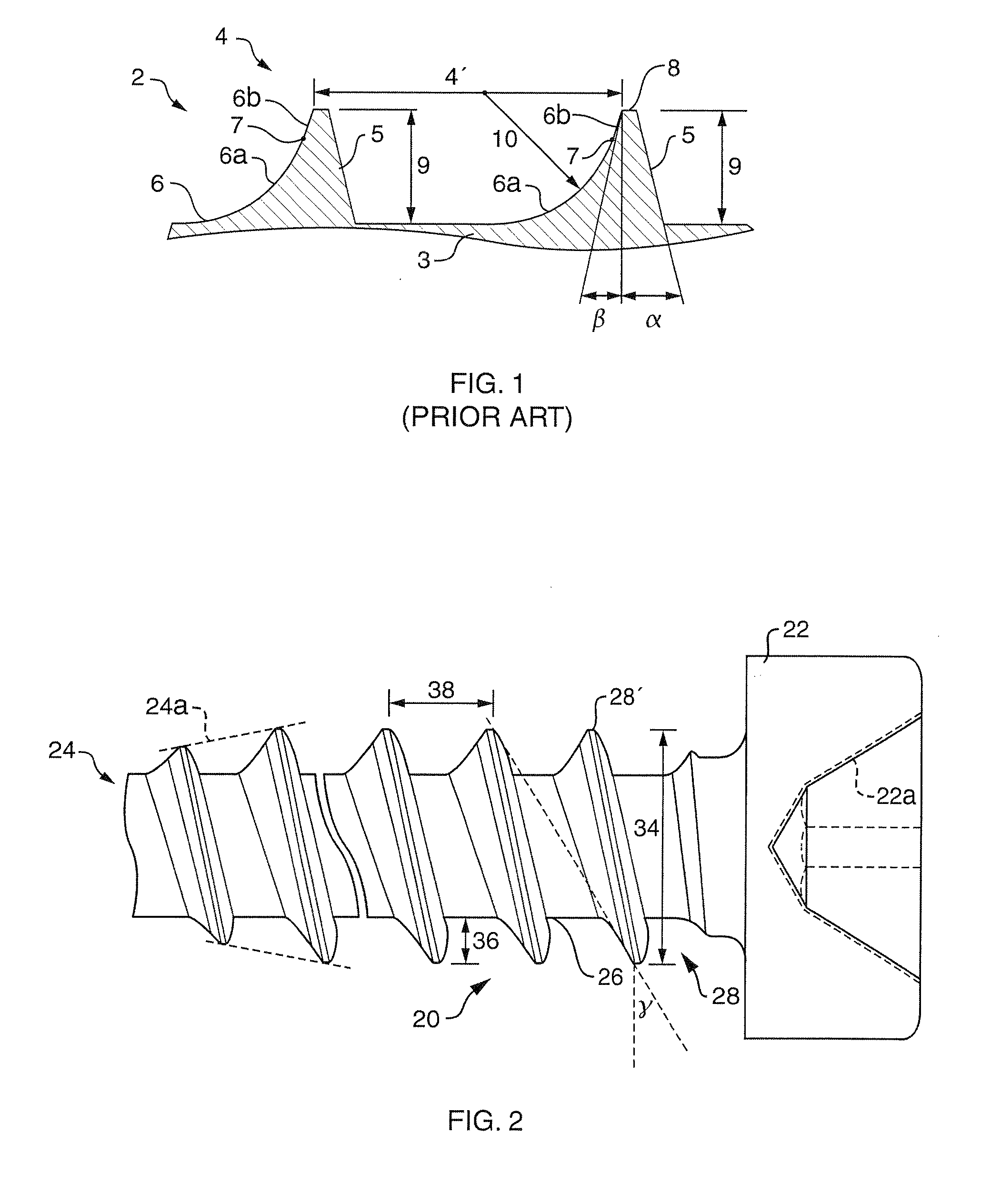

Thread forming fastener

A thread forming fastener for threading into a nut anchor of a pliable material wherein there is produced during the driving of the fastener a combination of forces that encourages the nut anchor material to flow smoothly and to develop a mating thread in the nut anchor that minimizes stress cracking and radial hoop stress as the mating thread is being formed. The fastener comprises a drive head and a shank extending from the head and having a longitudinal axis, the shank including a core and a thread having a selected axial pitch, a selected thread height and a profile which in axial cross-section includes a leading face, a trailing face and a tip. The leading face is composed of a radially inner concave portion having a first radius and which transitions smoothly to a radially outer convex portion having a second radius, the transition occurring at a point on the common tangent to those portions. The trailing face is composed of a radially inner linear portion which transitions at a selected transition location to a radially outer convex portion having a third radius. The profile also includes a convex blending portion having a fourth radius which blends together the radially outer leading and trailing face portions at the tip. The thread profile produces force vectors during assembly with the nut anchor that provide enhanced mating thread strength and improved resistance to nut anchor thread breakdown.

Owner:RES ENG & MFG

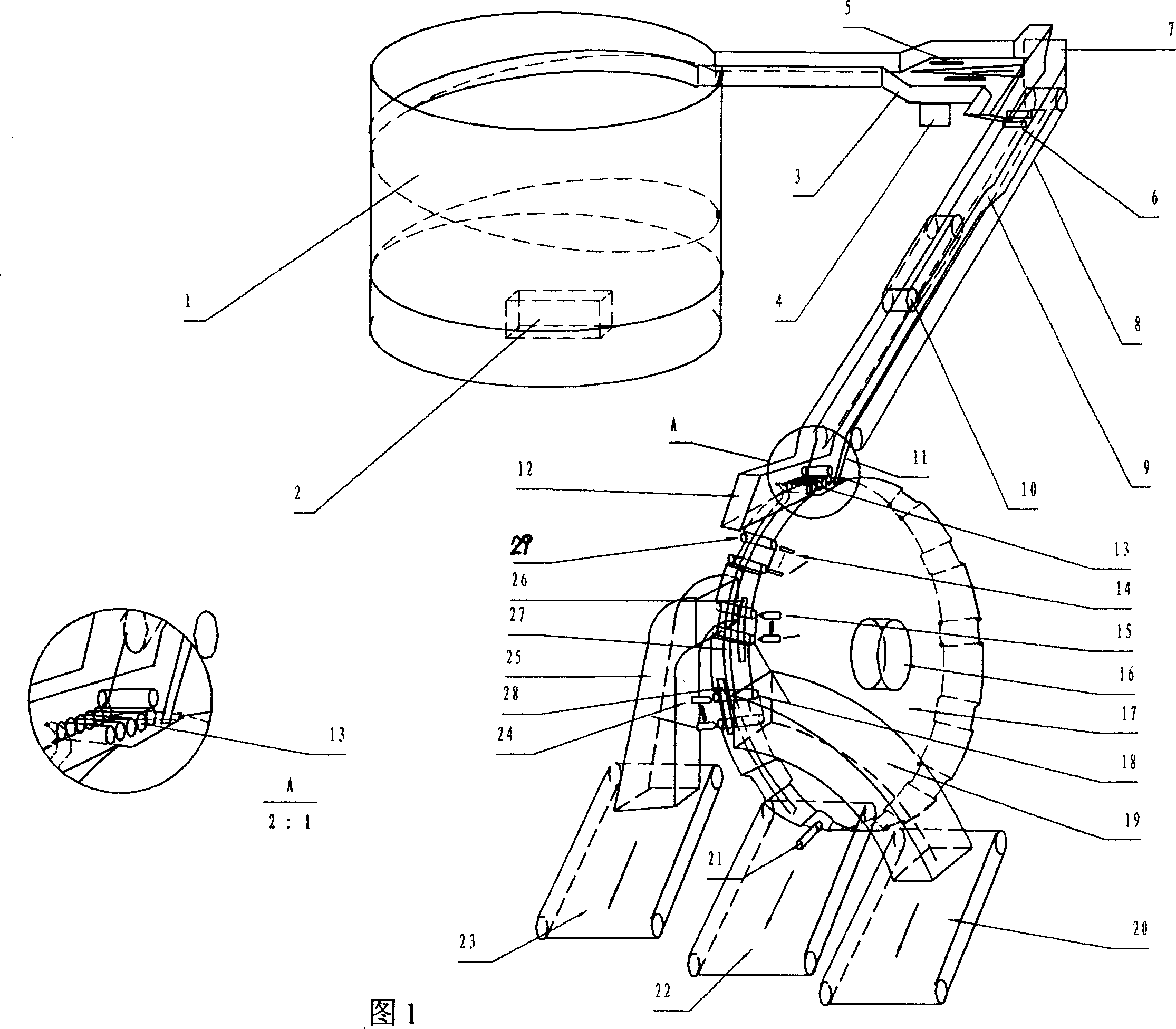

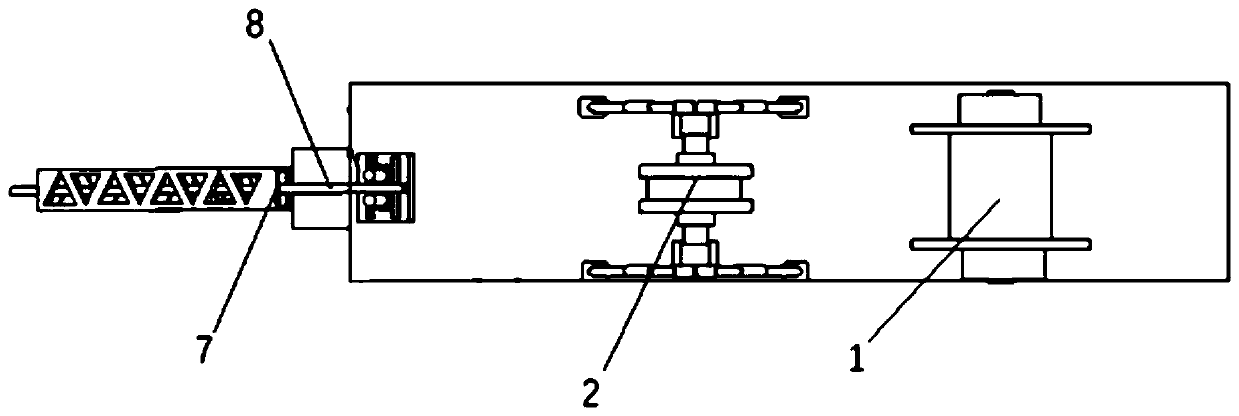

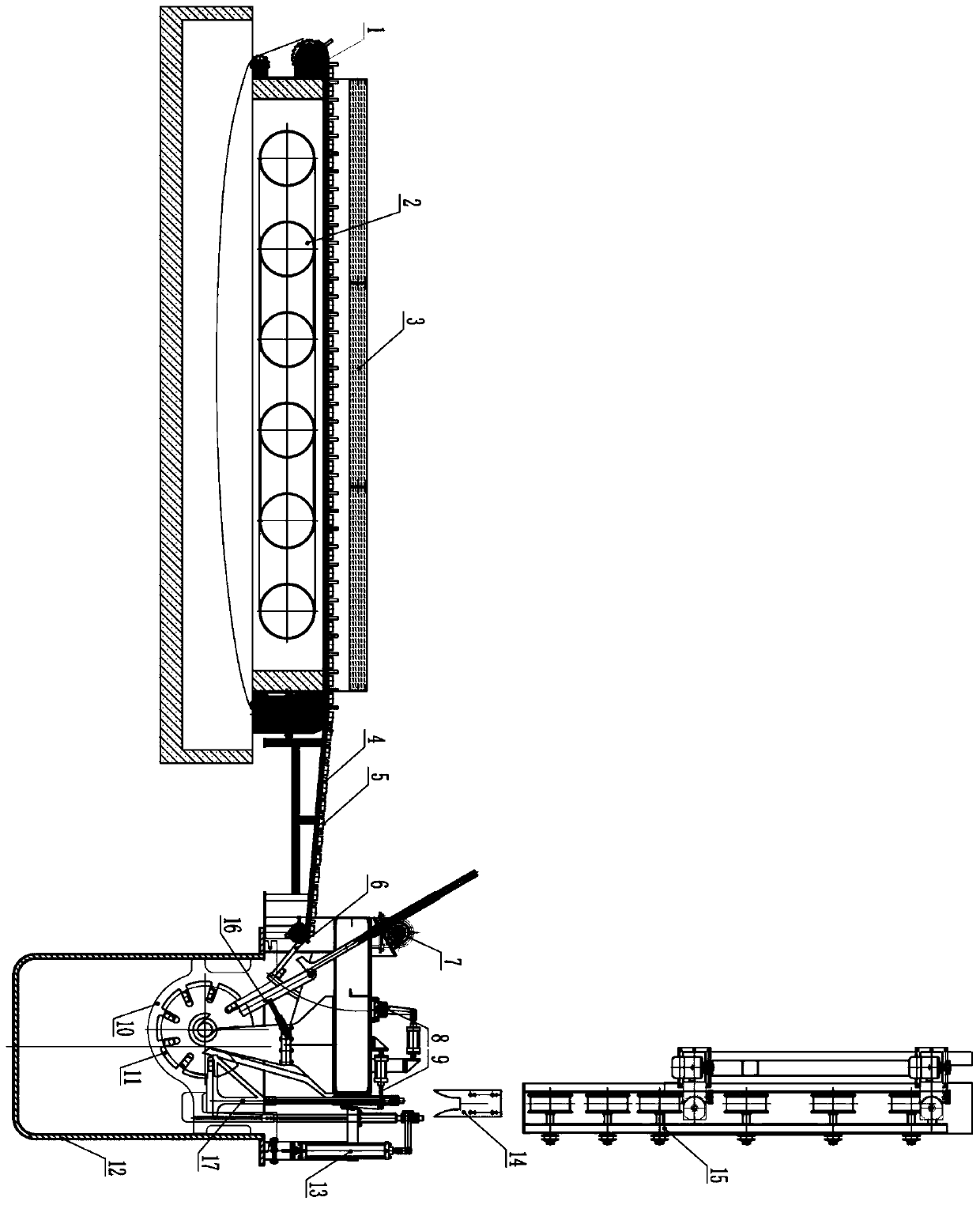

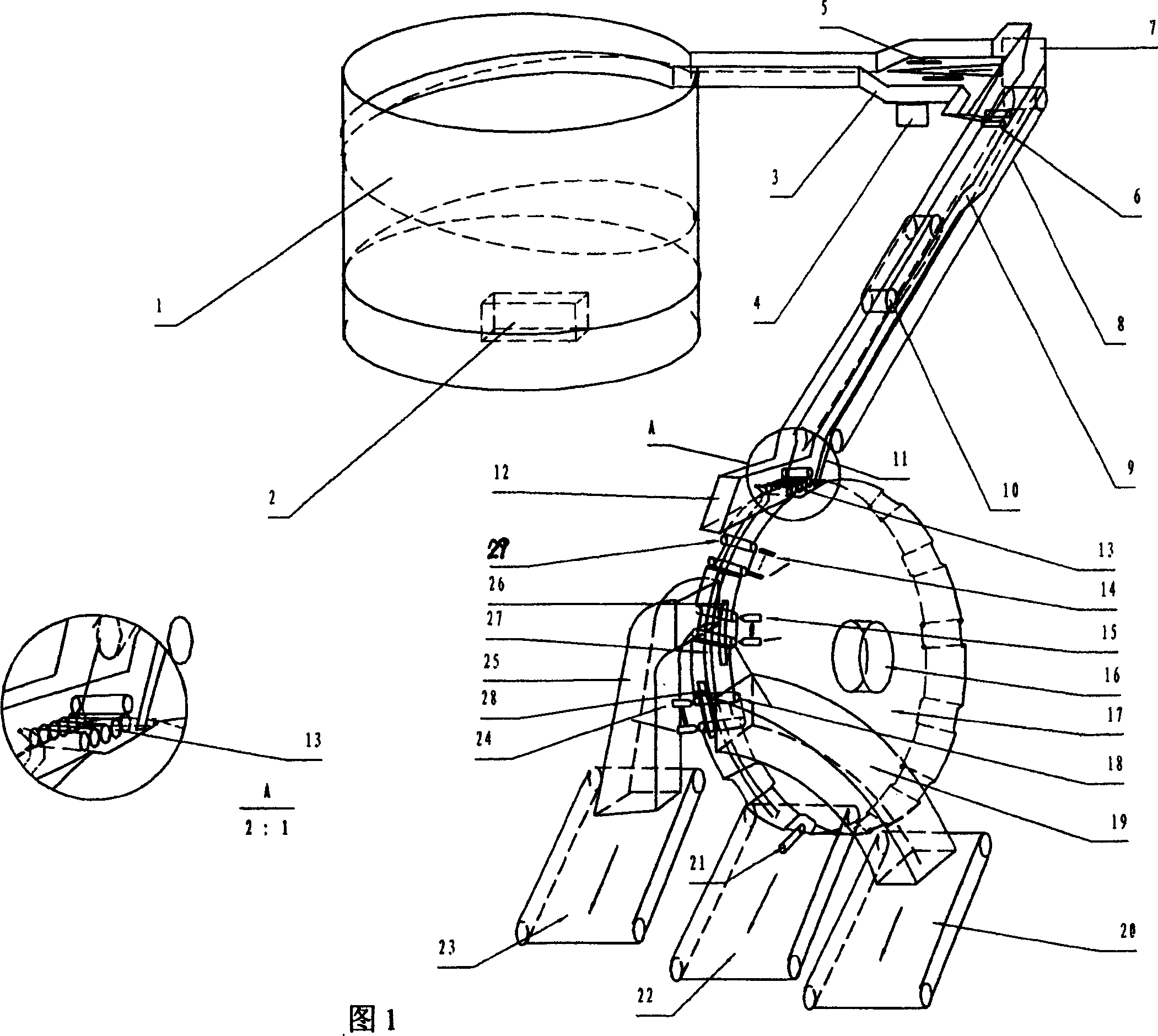

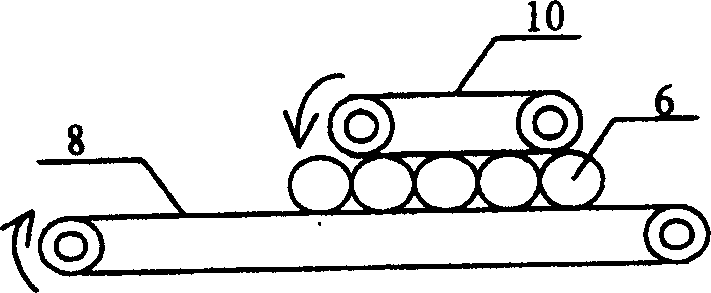

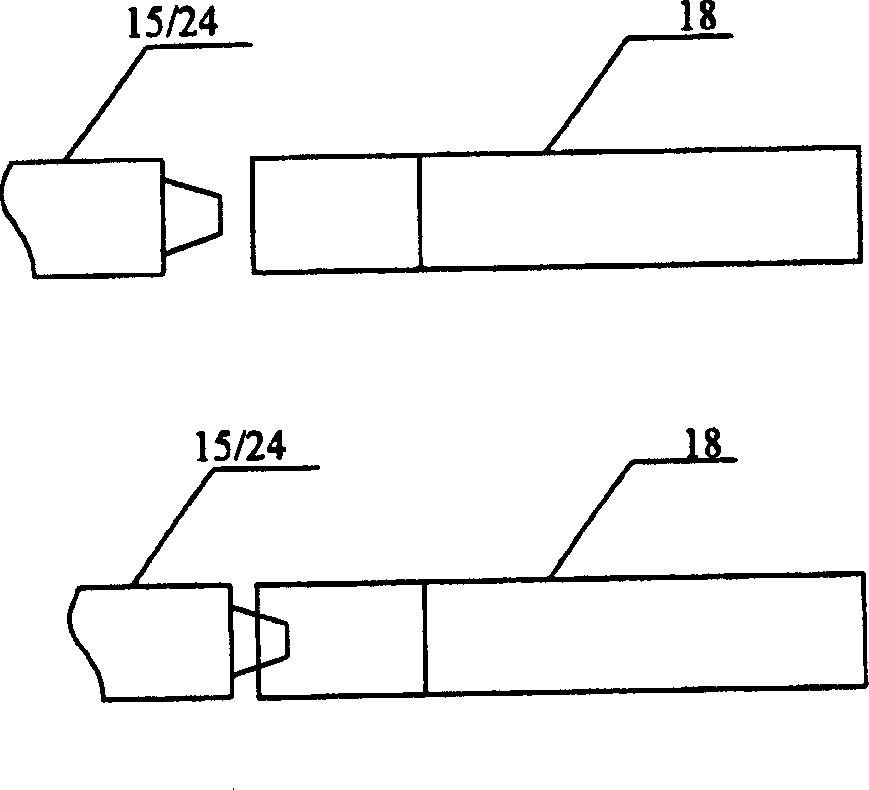

Method and apparatus for recovering inferior cigarettes and tobacco by gas separation

A method for recovering the tobacco shreds from the rejected and defective cigarettes by air separation features that the compressed air is pulsively sprayed onto the rejected and defective cigarettes to separate the tobacco shreds from paper and tip filters. Its apparatus is composed of feeding unit, shaper, conveyer, pulse spray separator, shreds recovering unit, papper and tip filter recovering unit, and electric controller.

Owner:魏积斌 +2

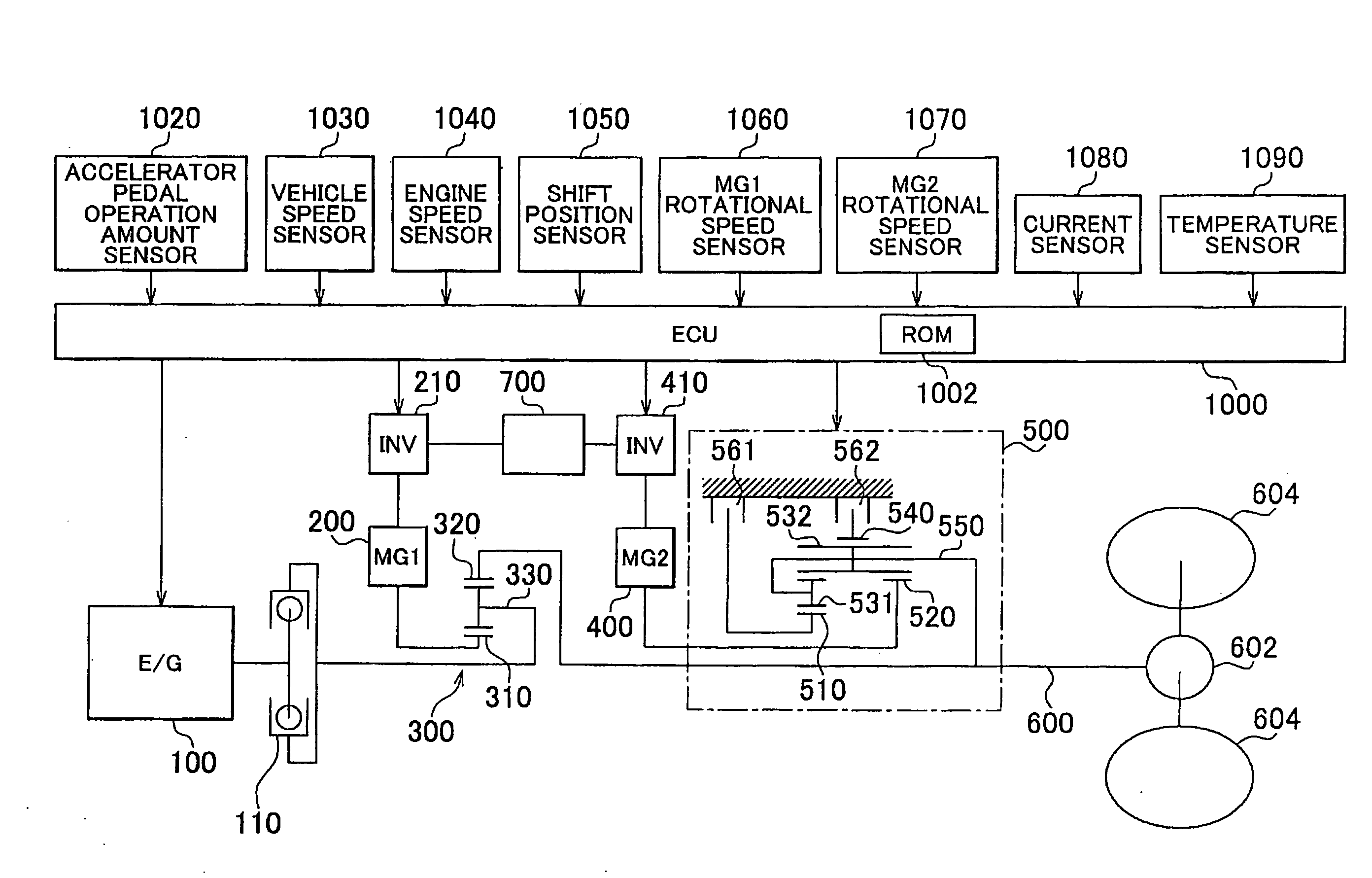

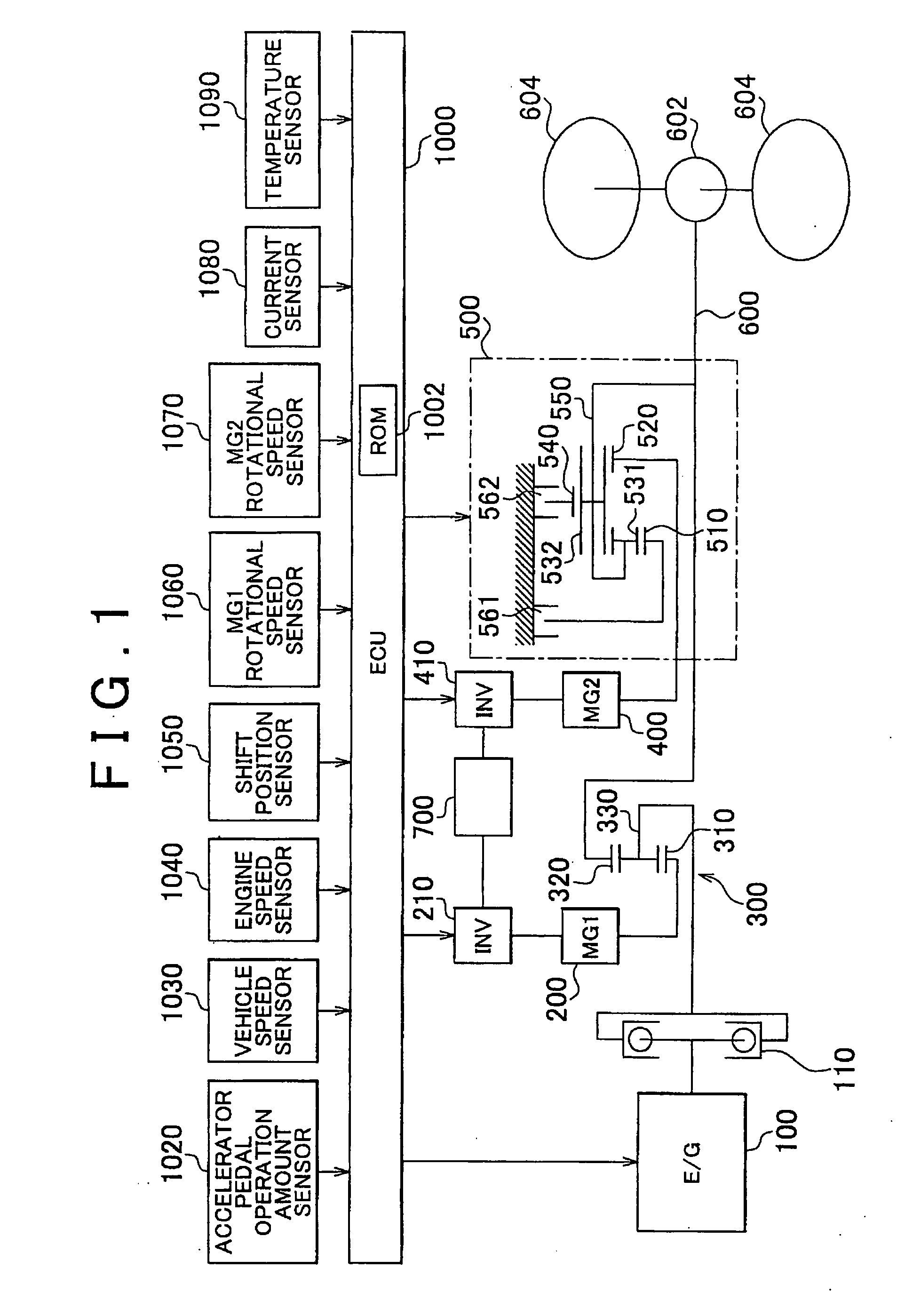

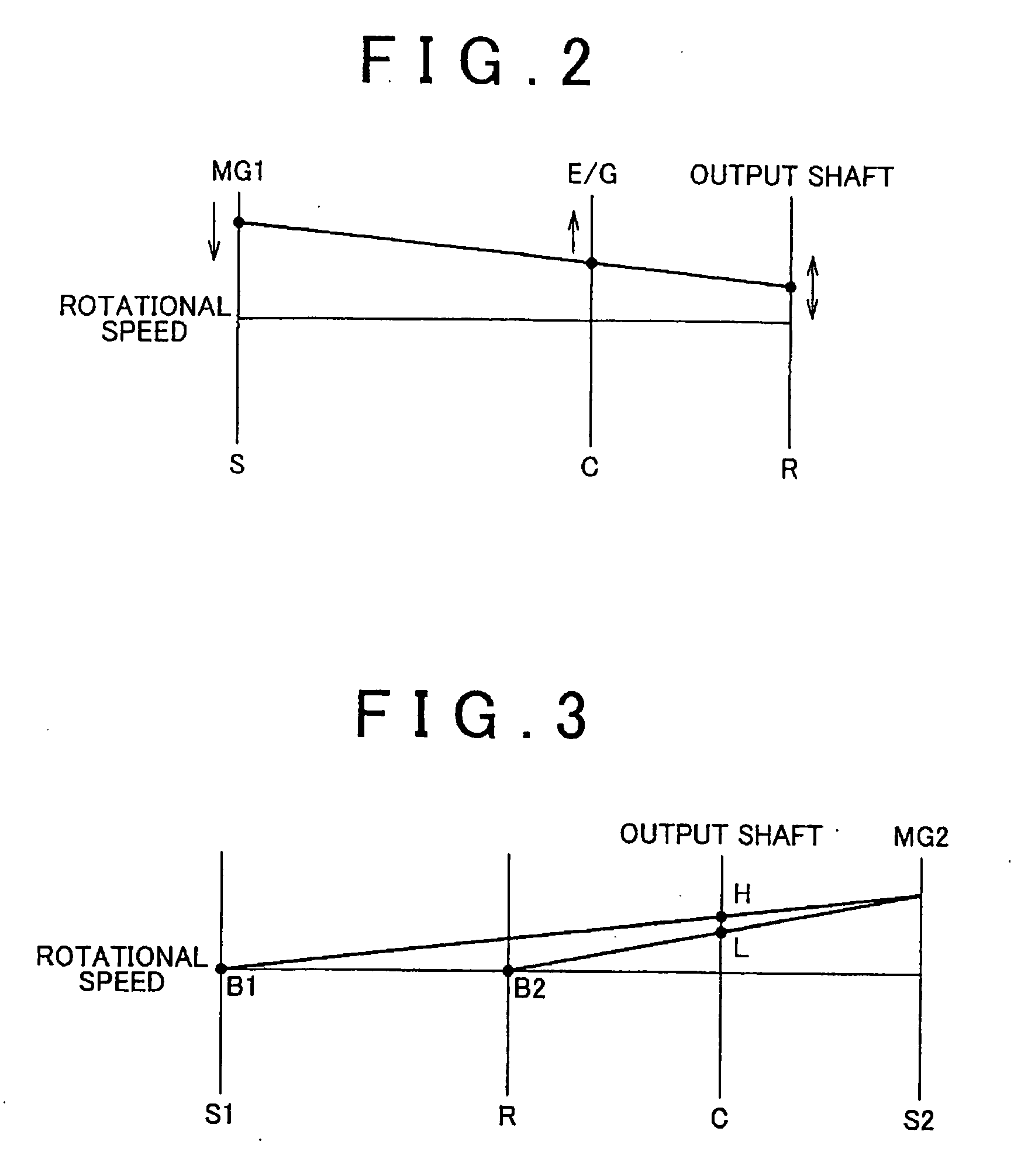

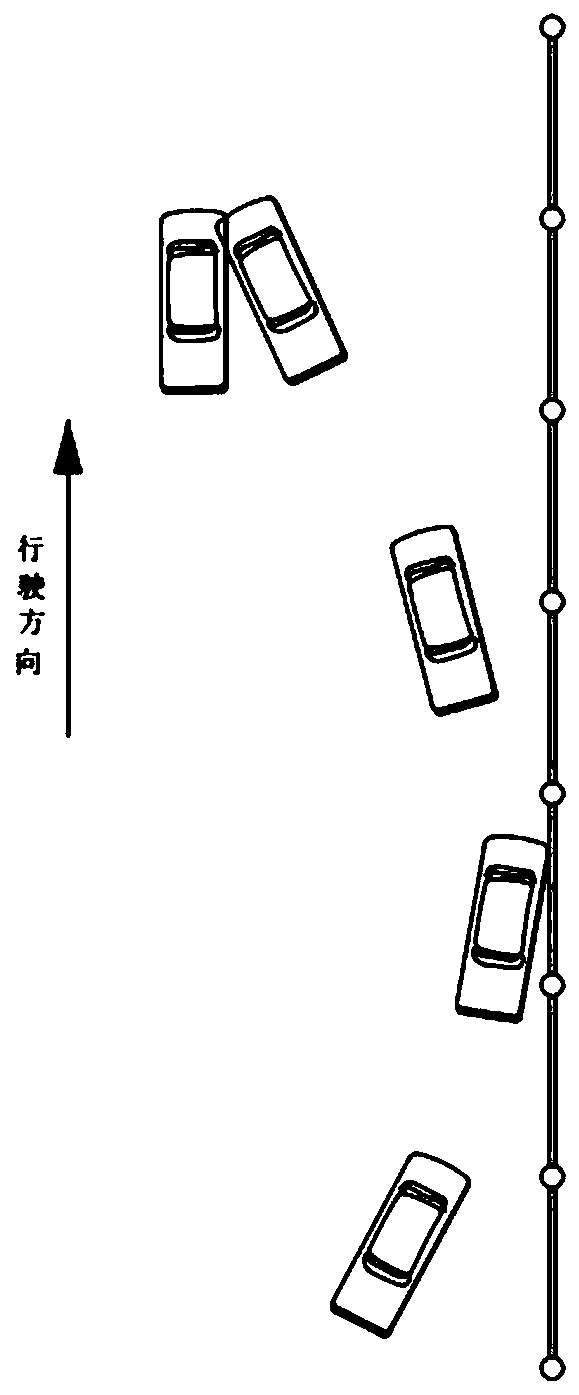

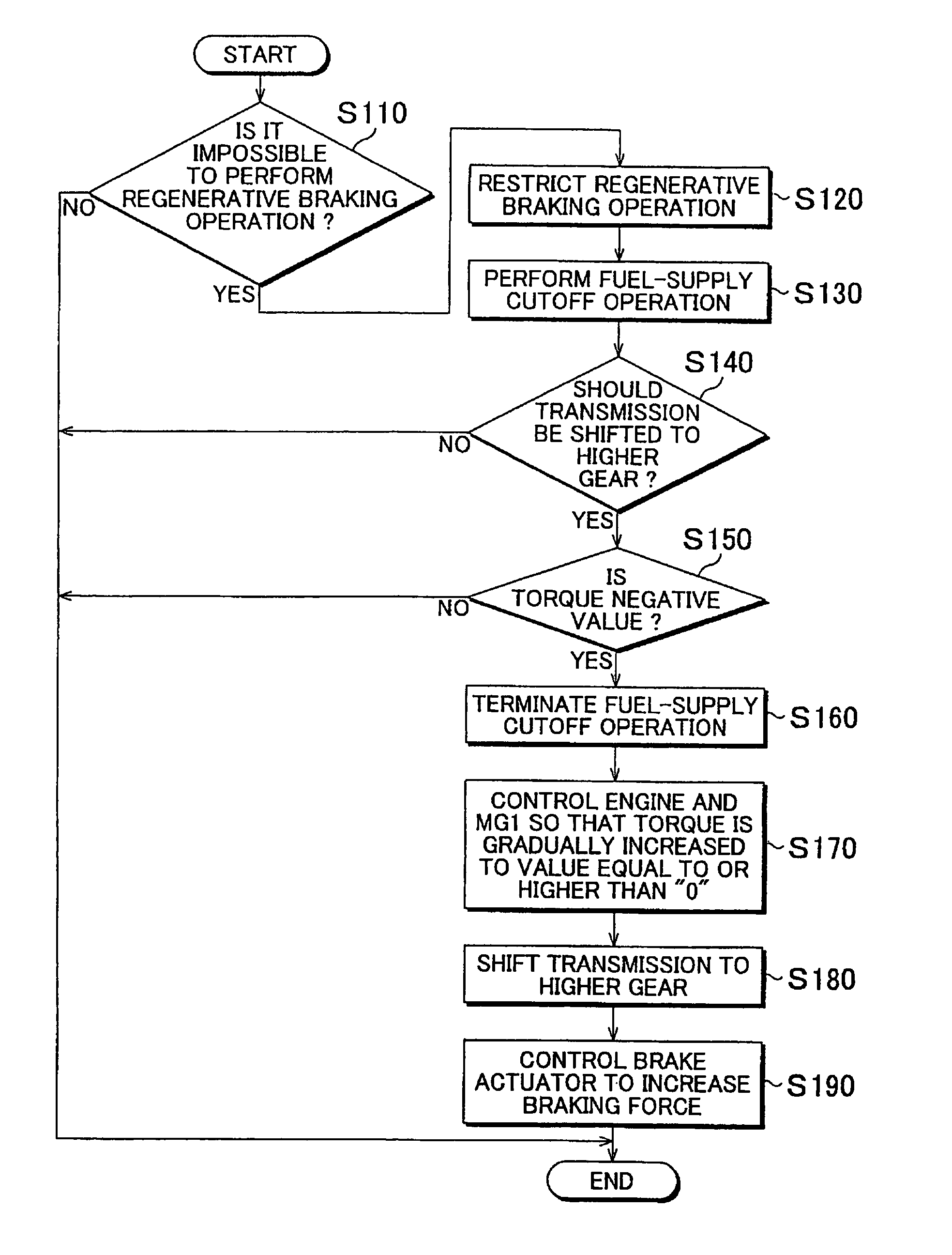

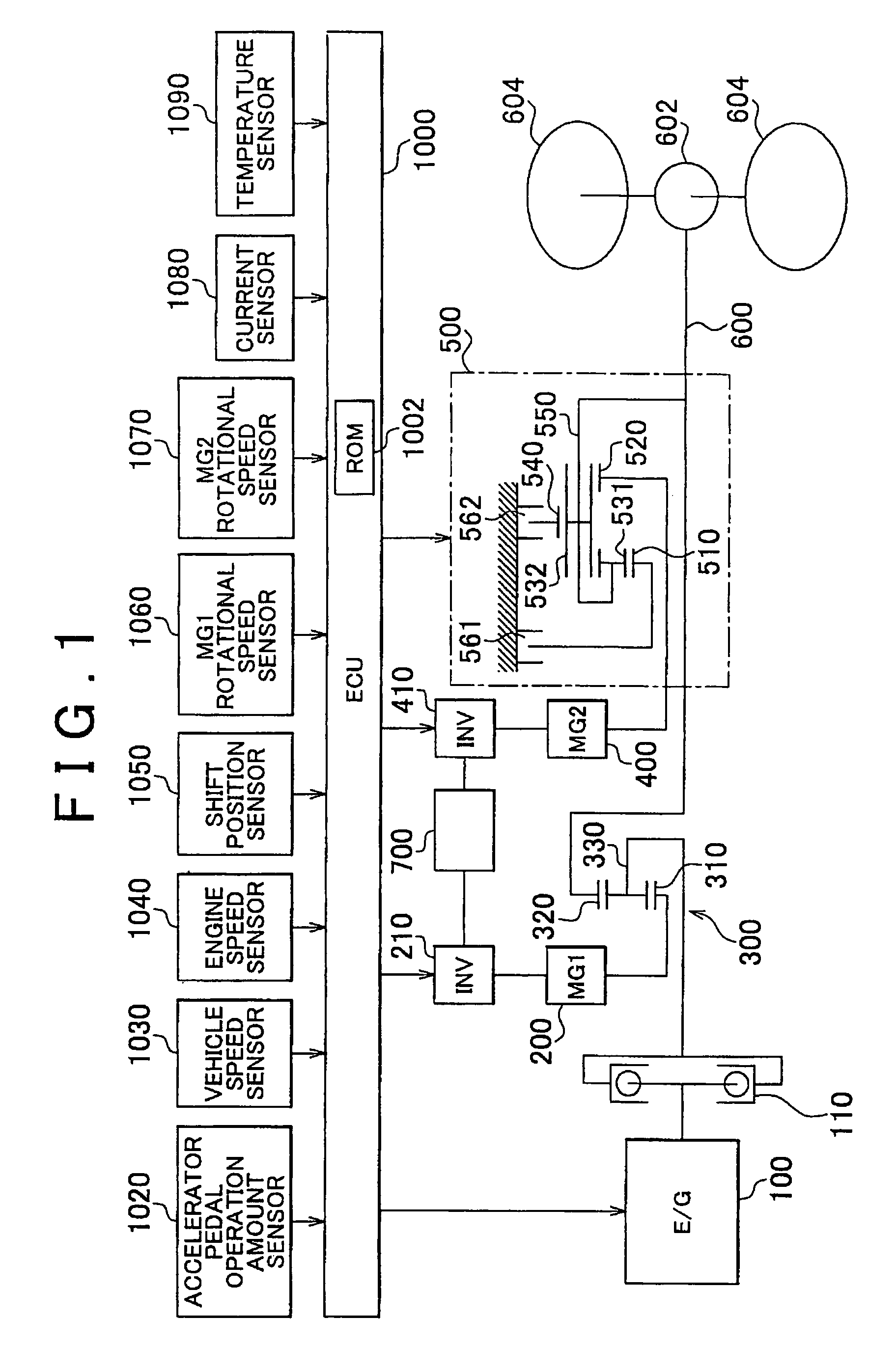

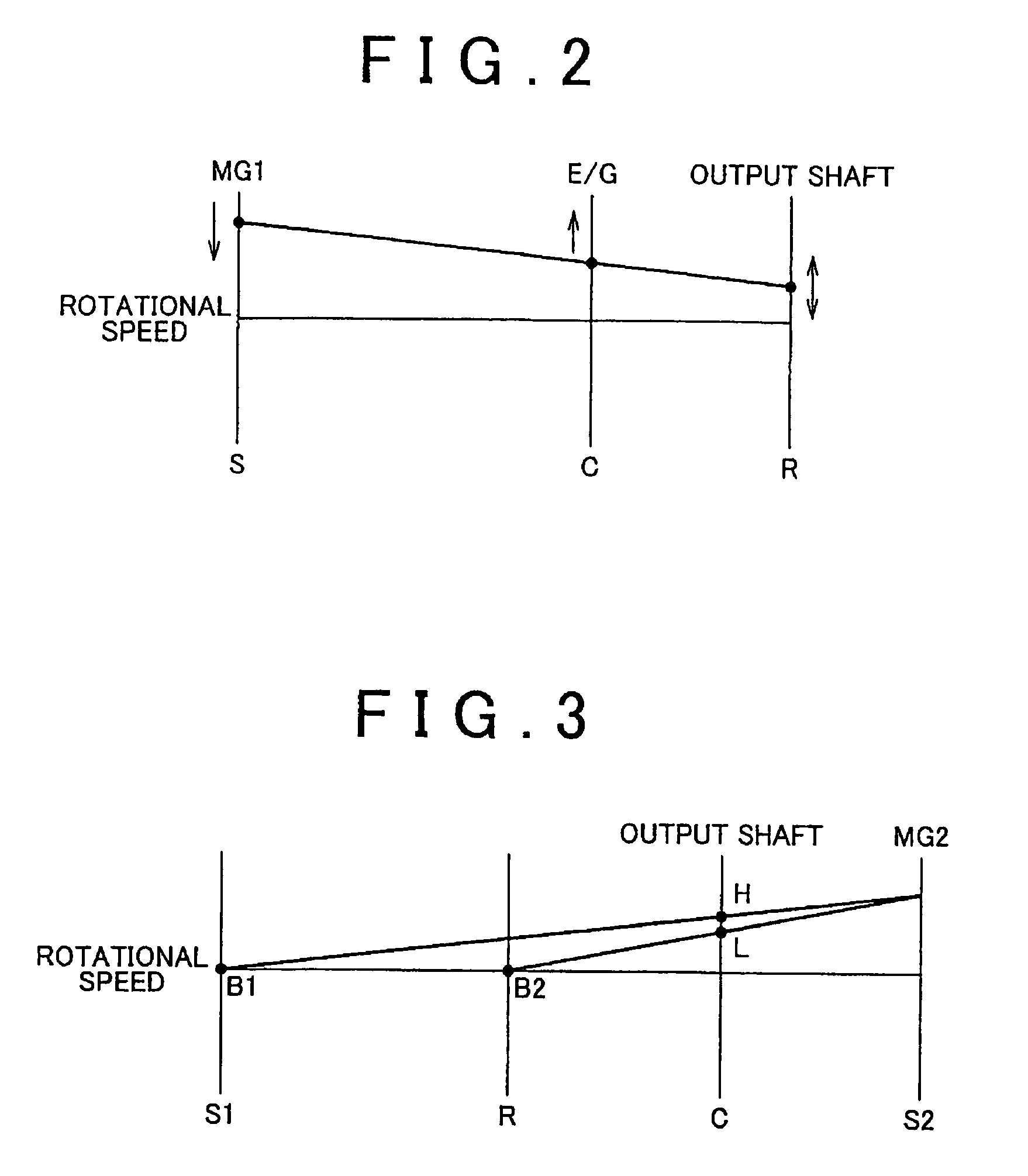

Control device and control method for powertrain, program for implementing the control method, and recording medium containing the program

ActiveUS20080153660A1Reduce shockPrevent change of directionHybrid vehiclesDigital data processing detailsExecution controlVariator

A shock caused due to a change in the direction of torque transferred to an output shaft is reduced. There is provided a control device for a powertrain including a drive power source that transfers torque to an output shaft connected to a wheel of a vehicle, and a rotary electric machine that transfers torque to the output shaft via a transmission. When electric power generation performed using the rotary electric machine is restricted, if torque that decelerates the vehicle is transferred from the drive power source to the output shaft, a control is executed so that torque that does not decelerate the vehicle is transferred from the drive power source to the output shaft, and a shift control over the transmission is executed.

Owner:TOYOTA JIDOSHA KK +1

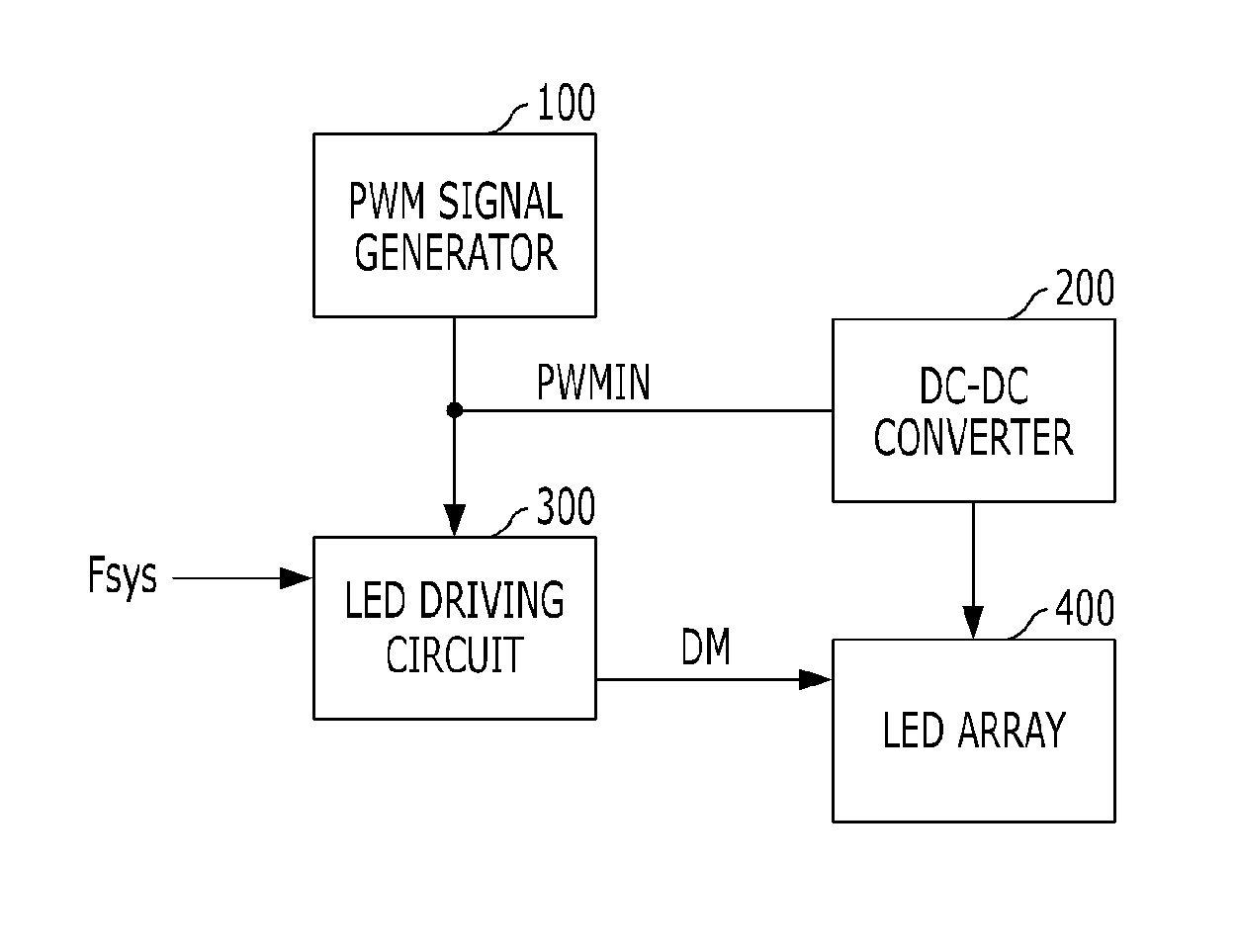

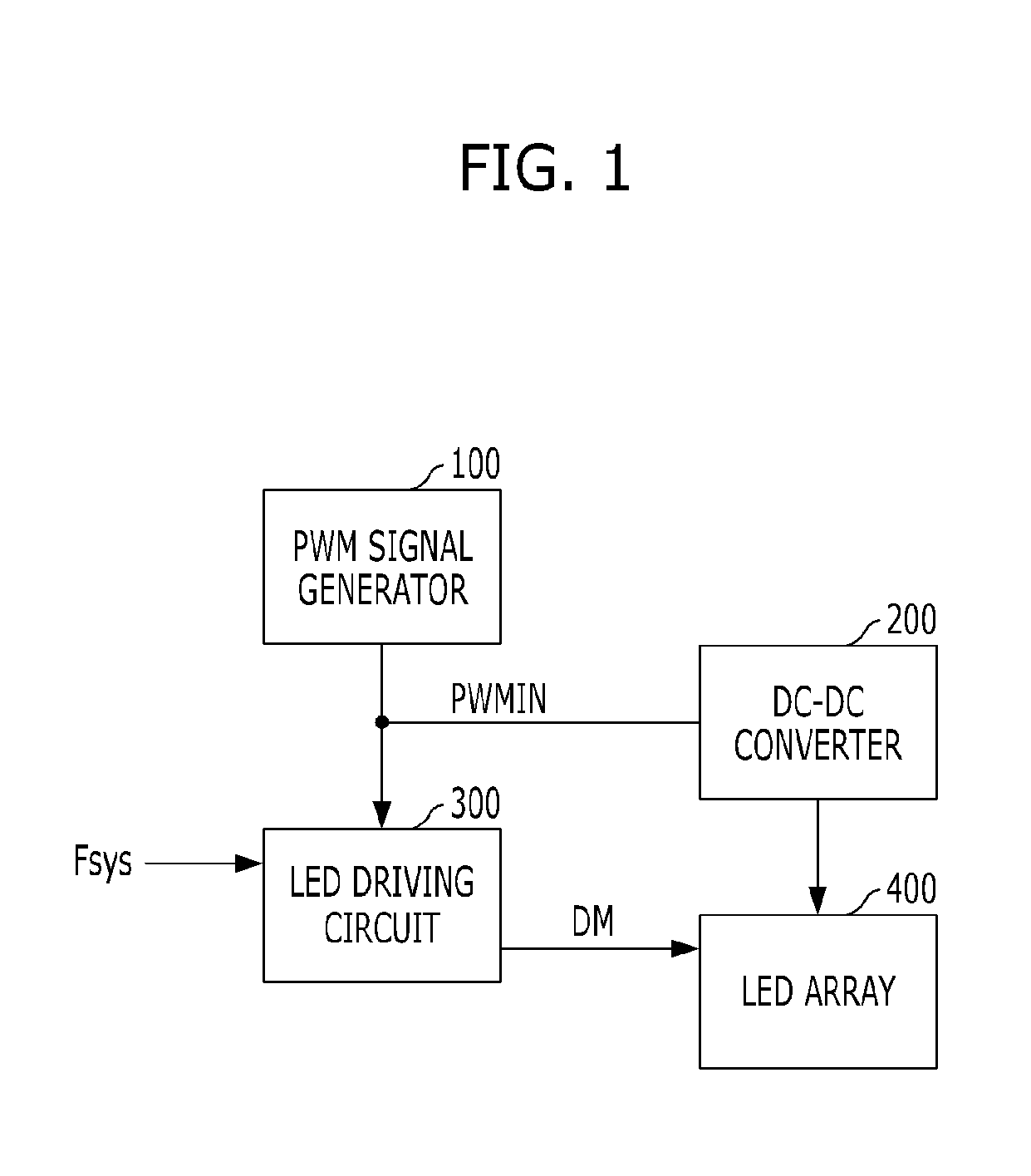

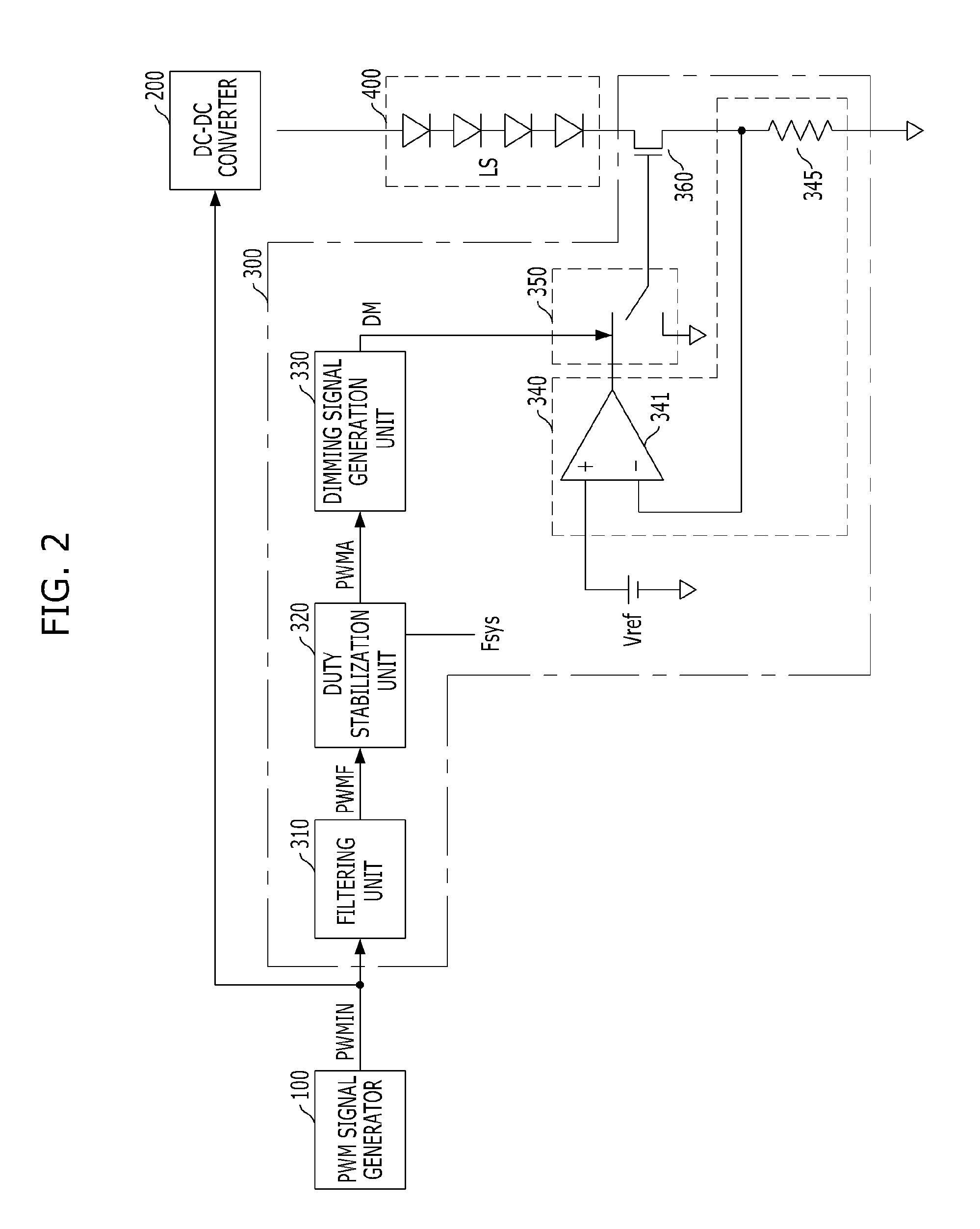

Circuit and method for driving a light emitting diode for a backlight, and backlight driving apparatus using the same

InactiveUS20110267387A1Prevent change of directionElectrical apparatusCathode-ray tube indicatorsEngineeringPwm signals

A circuit and method for driving a light emitting diode for a backlight, and a backlight driving apparatus using the same is provided. A circuit for driving a light emitting diode (LED) for a backlight includes a filtering unit configured to receive a pulse width modulation (PWM) signal and remove noise of a predetermined band, a duty stabilization unit configured to stabilize a duty of a PWM signal filtered by the filtering unit, a dimming signal generation unit configured to generate a dimming signal based on a PWM signal stabilized by the duty stabilization unit, and an LED driving unit configured to drive the LED for the backlight based on the dimming signal generated by the dimming signal generation unit.

Owner:MAGNACHIP SEMICONDUCTOR LTD

Four-position rocker switch for electrosurgical handpiece

ActiveUS8172838B2Easy to operateQuality improvementSurgical instrument detailsElectric switchesEngineeringRocker arm

A surgical apparatus includes an actuation unit disposed on a handle and a control unit providing at least three modes for controlling the electrical instrument. The actuation unit contains a switching rocker with an operating element, which is rotatable about a rocker axis that can be shifted perpendicular to the surface of the handle, so that starting from an initial position a first or second function position can be reached by forwards or backwards rotation about the rocker axis, and a third function position can be reached by pressing the operating element inward, two sensors being disposed on the operating element, one on the left and the other on the right side of the rocker axis, in such a way that by means of the sensors the function position selected by means of the switching rocker can be determined by the control unit.

Owner:ERBE ELEKTROMEDIZIN GMBH

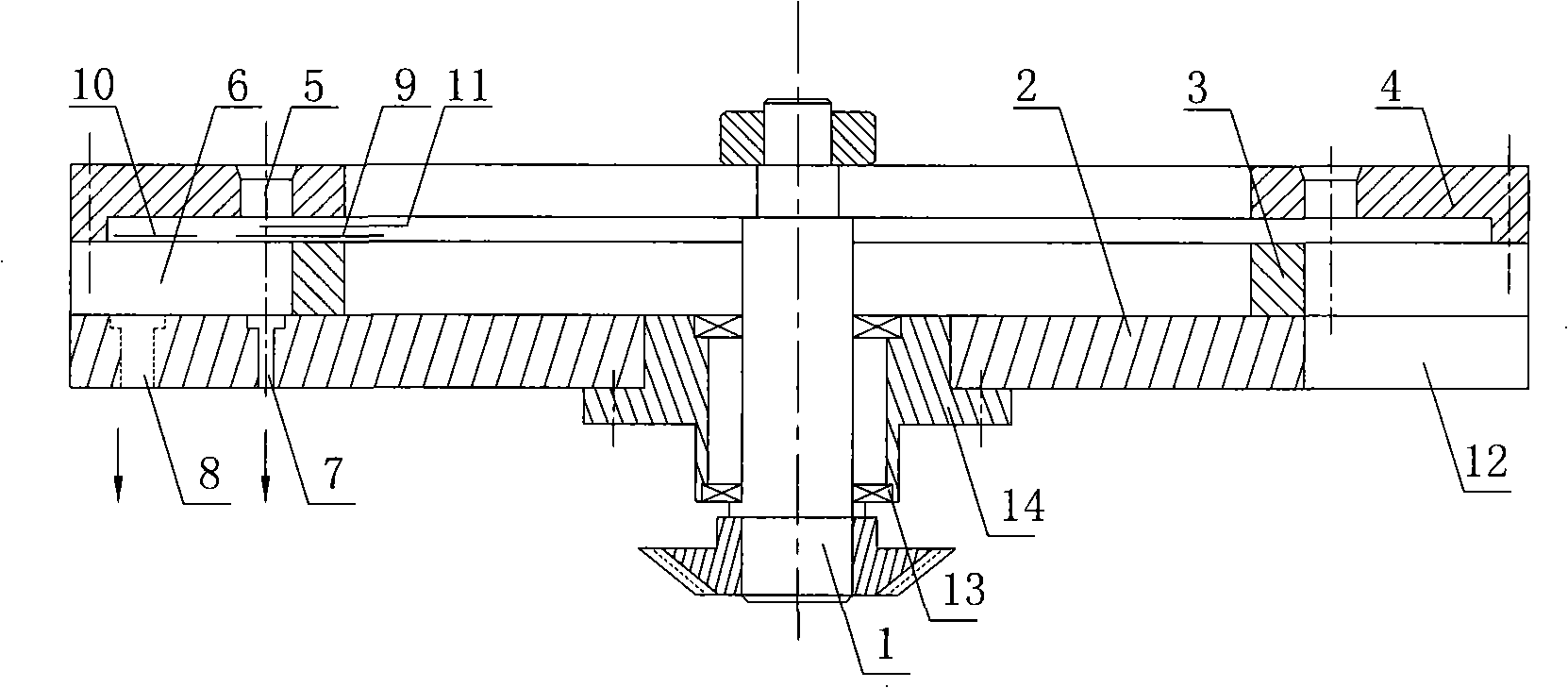

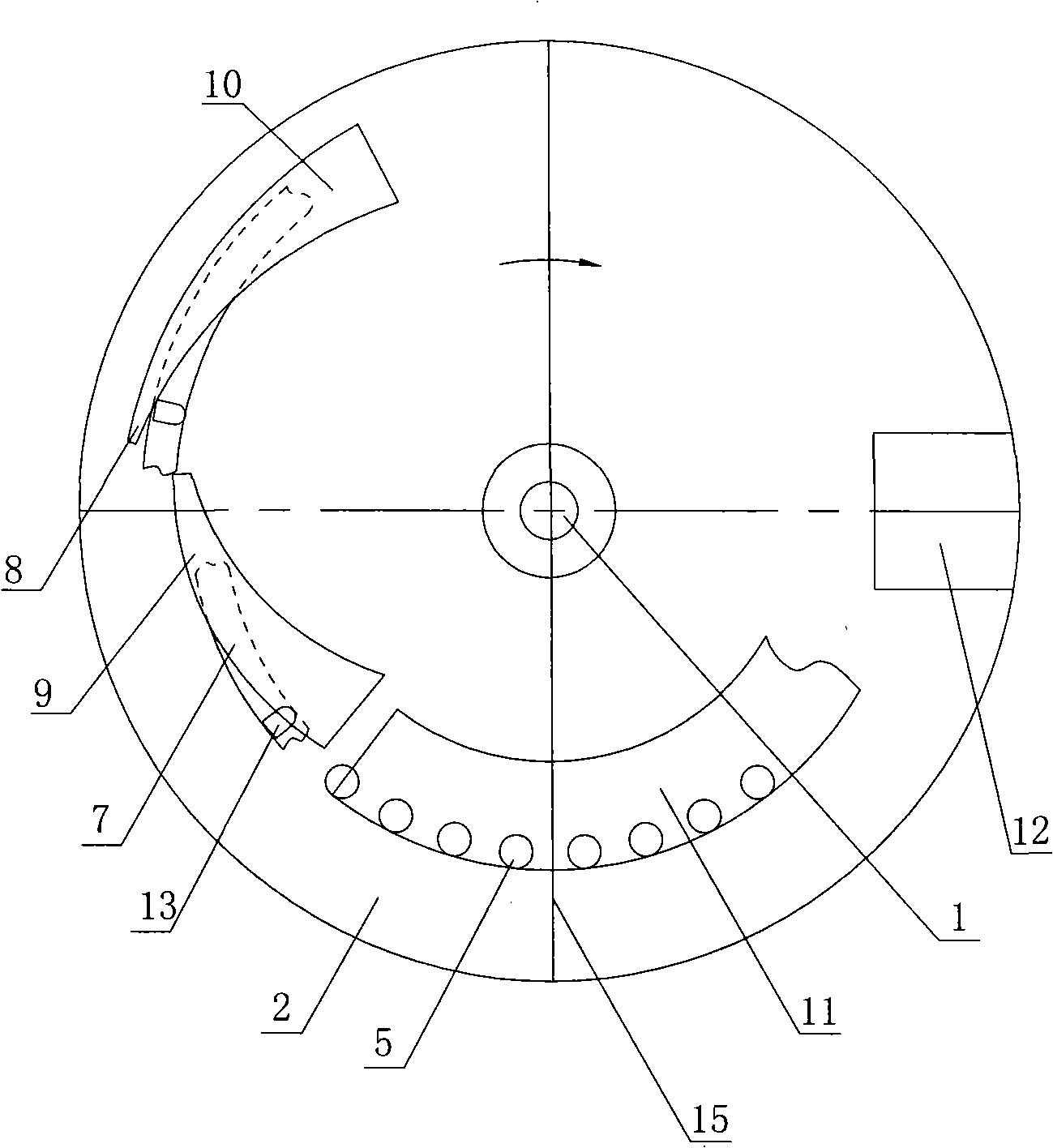

Orientation arrangement apparatus for capsule and pill

InactiveCN101317810APrevent change of directionImprove hygiene standardsPharmaceutical product form changeEngineeringMechanical engineering

A capsule orientation arrangement device belongs to the processing machinery field of medicine capsules. Currently, the orientation arrangement for sheathing capsules is done by manual operation and no effective capsule automatic sheathing equipment is available. The capsule orientation arrangement device is provided with a consequent striker plate and an obsequent striker plate which are in interoperation with a consequent material collecting slotted hole and an obsequent material collecting slotted hole. No matter the opening of the capsule is upward or downward, the opening can be inversely arranged in a horizontal material collecting component in a way being opposite to a center shaft, thus completing the orientation arrangement to effectively increase the efficiency of production. If the consequent and the obsequent striker plates are symmetrically arranged on both sides of a sheathing device to orientate the end A and the end B of the capsule, and a hollow capsule can be sheathed automatically. The sheathed capsule has good uniformity and high sanitary standards, thus facilitating subsequent processing.

Owner:陈春雷

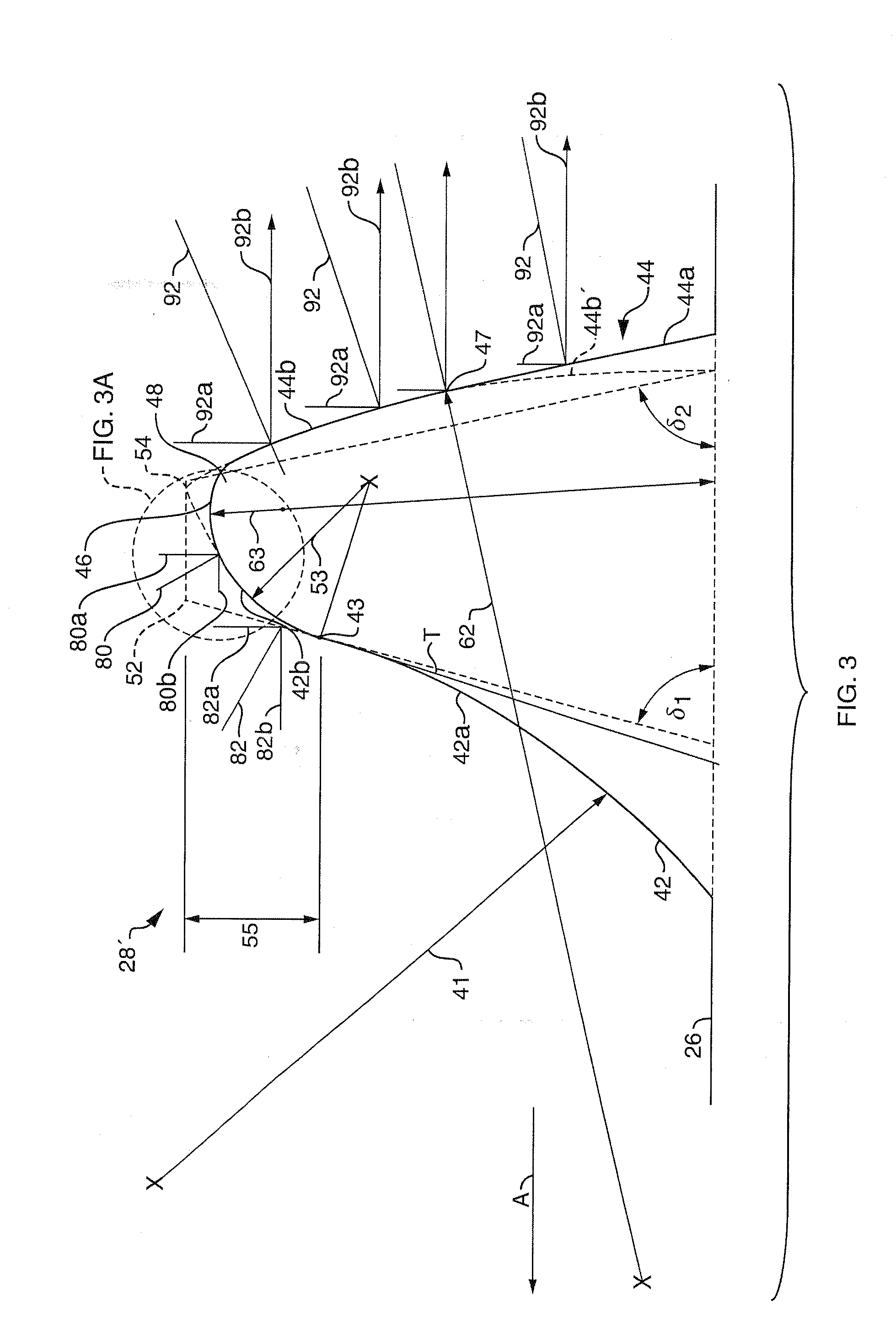

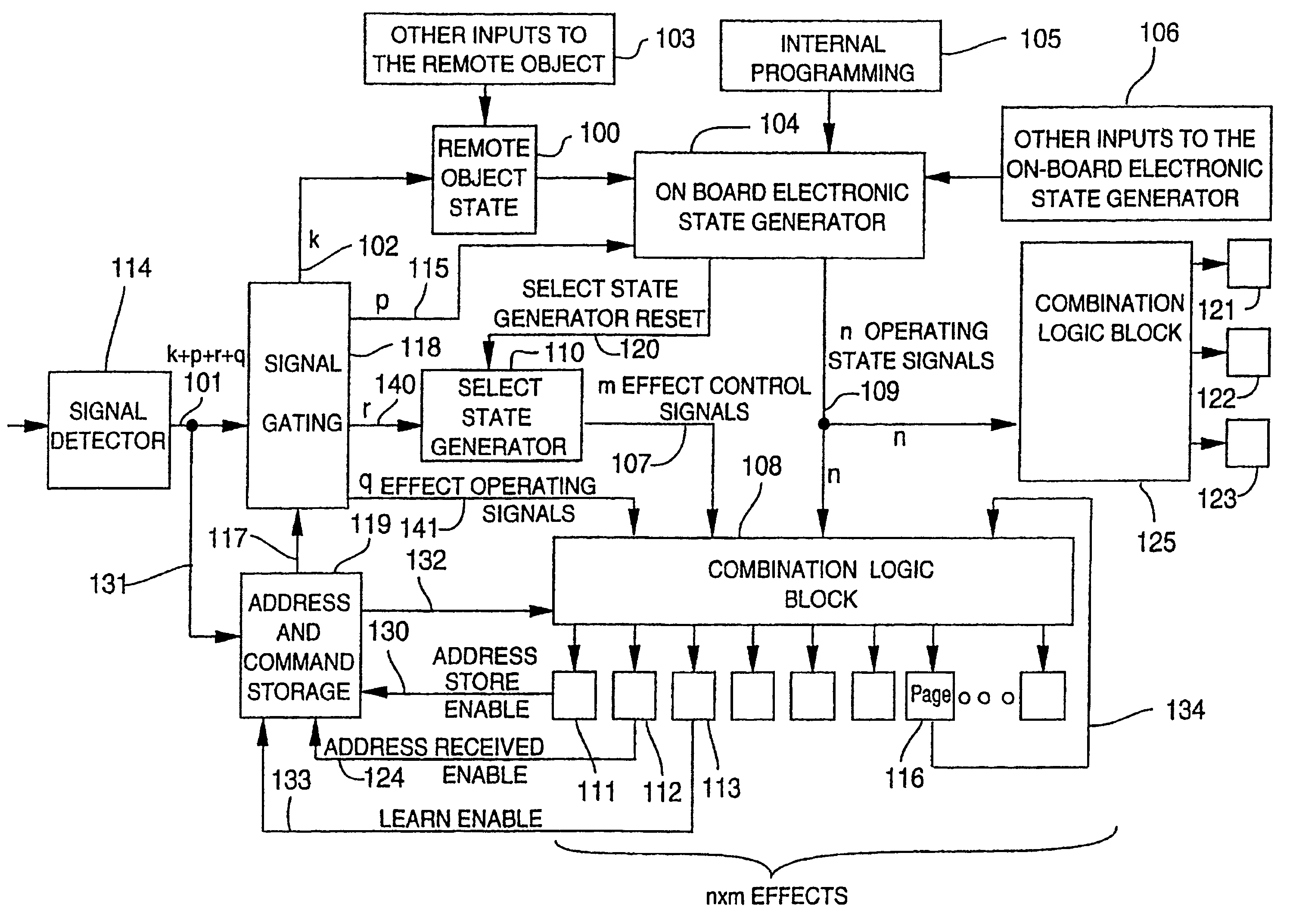

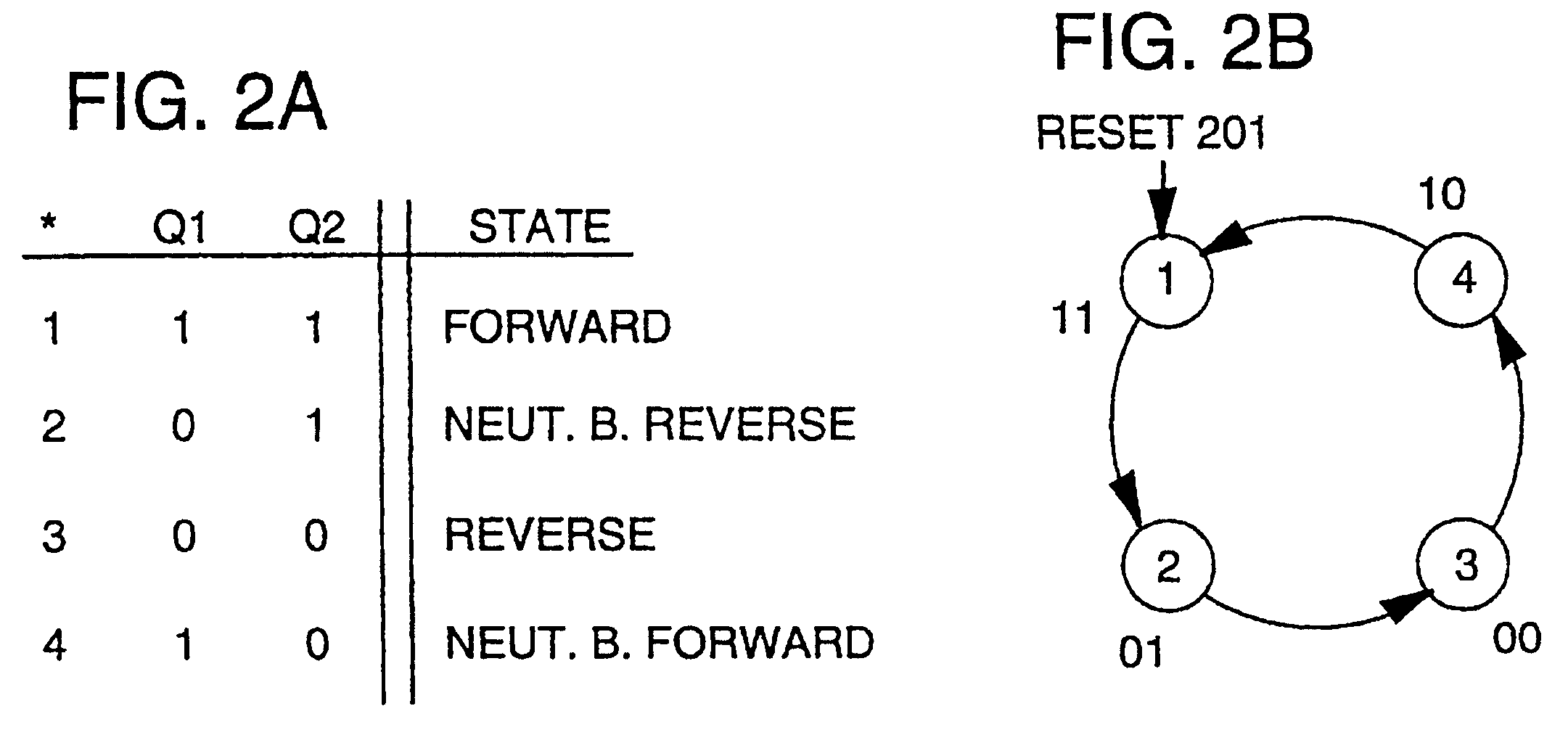

Signaling techniques for DC track powered model railroads

InactiveUSRE42284E1Simplify remote control operationExpand remote control operationDC motor speed/torque controlCircuit arrangementsRemote controlOn board

Electronic circuits and methods are provided for remote control of a locomotive in a model railroad layout having an interruptible DC power supply coupled to the railroad track. The locomotive motor is isolated from the track so as to allow use of polarity reversals on the track power signal for controlling remote effects in the locomotive such as sound effects. An on-board electronic state generator is provided in the locomotive for maintaining one at a time of a predetermined set of states, at least one of the states having a corresponding remote effect associated therewith. Remote control signals such as a reverse in polarity of the DC track power signal are used to clock the state generator to a desired state, thereby permitting control of a plurality of remote effects using only the traditional DC power supply interface. The locomotive motor is controlled by a motor reverse unit so that the motor direction is controllable independently of the polarity of the DC power signal applied to the track. Accordingly, both motor direction and remote effects are controllable using only the throttle and polarity reversal switch which are available in known DC model railroad power supplies.

Owner:SEVERSON FREDERICK E +1

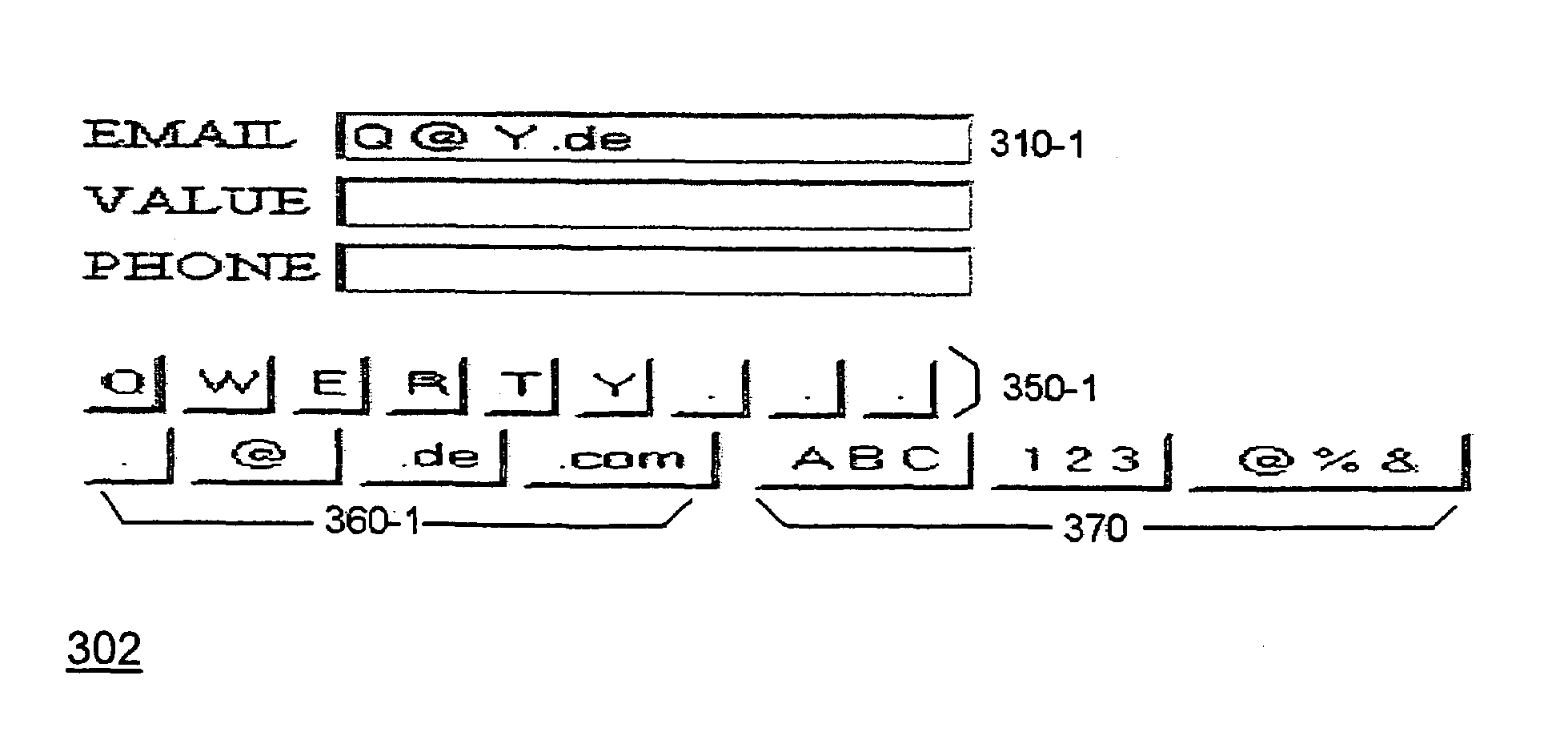

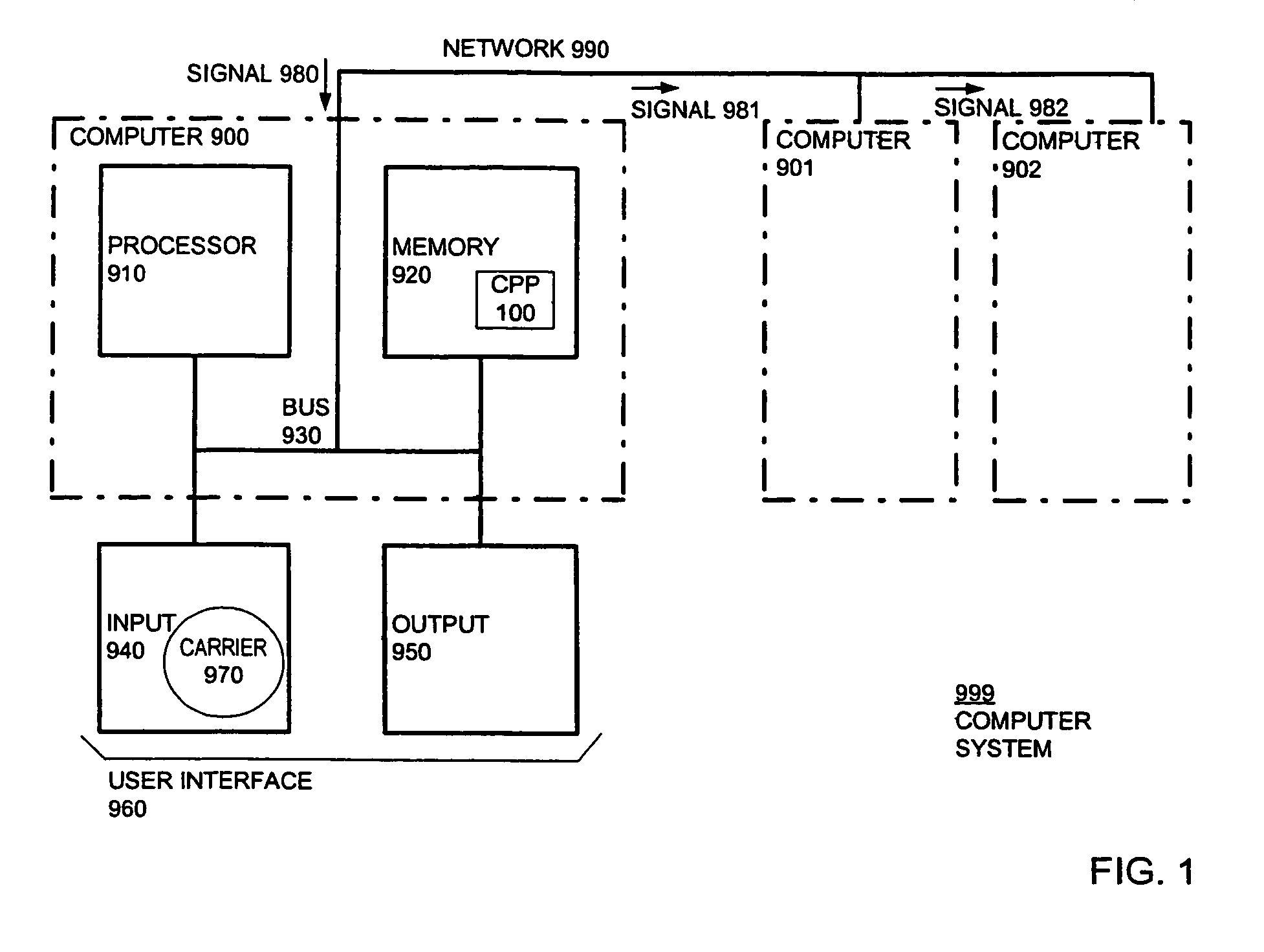

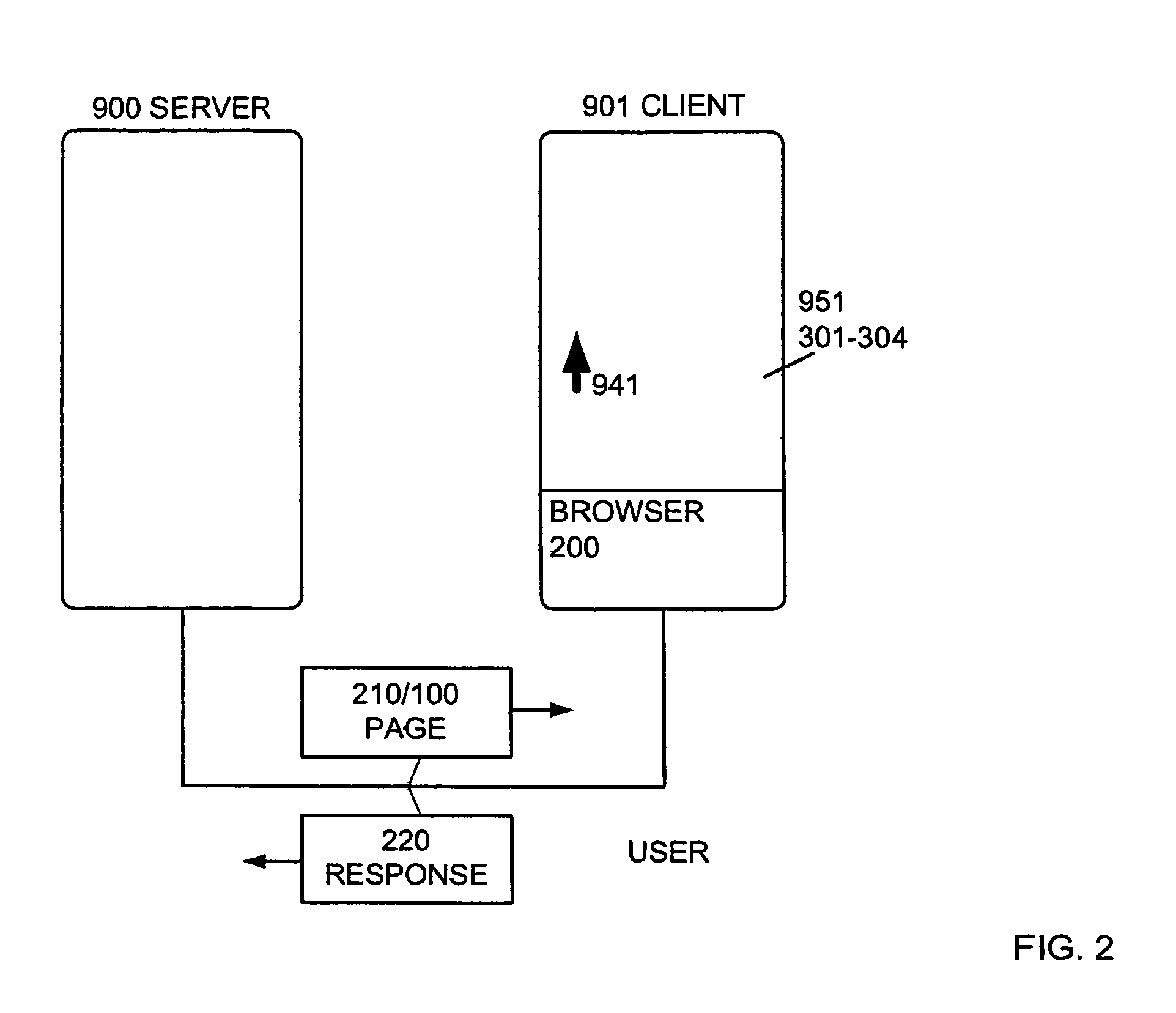

Operating a browser to display first and second virtual keyboard areas that the user changes directly or indirectly

ActiveUS7383342B2Solve situationPrevent change of directionInput/output for user-computer interactionAlphabetical characters enteringInput fieldInput device

Operating a browser that interprets a markup page and thereby displays a virtual keyboard (350) to a user. The operation comprises: displaying (405) a first keyboard area (350); presenting (410) first and second input fields of first and second types, respectively, to the user; selecting (420) an input field by relating an input device to either the first input field or the second input field; displaying (430) a second keyboard area corresponding to the type of the selected input field; reading (430) input from the user from the first keyboard area and from the second keyboard area to the selected field; and changing (450) the first keyboard area according to user commands to a keyboard selector.

Owner:SAP AG

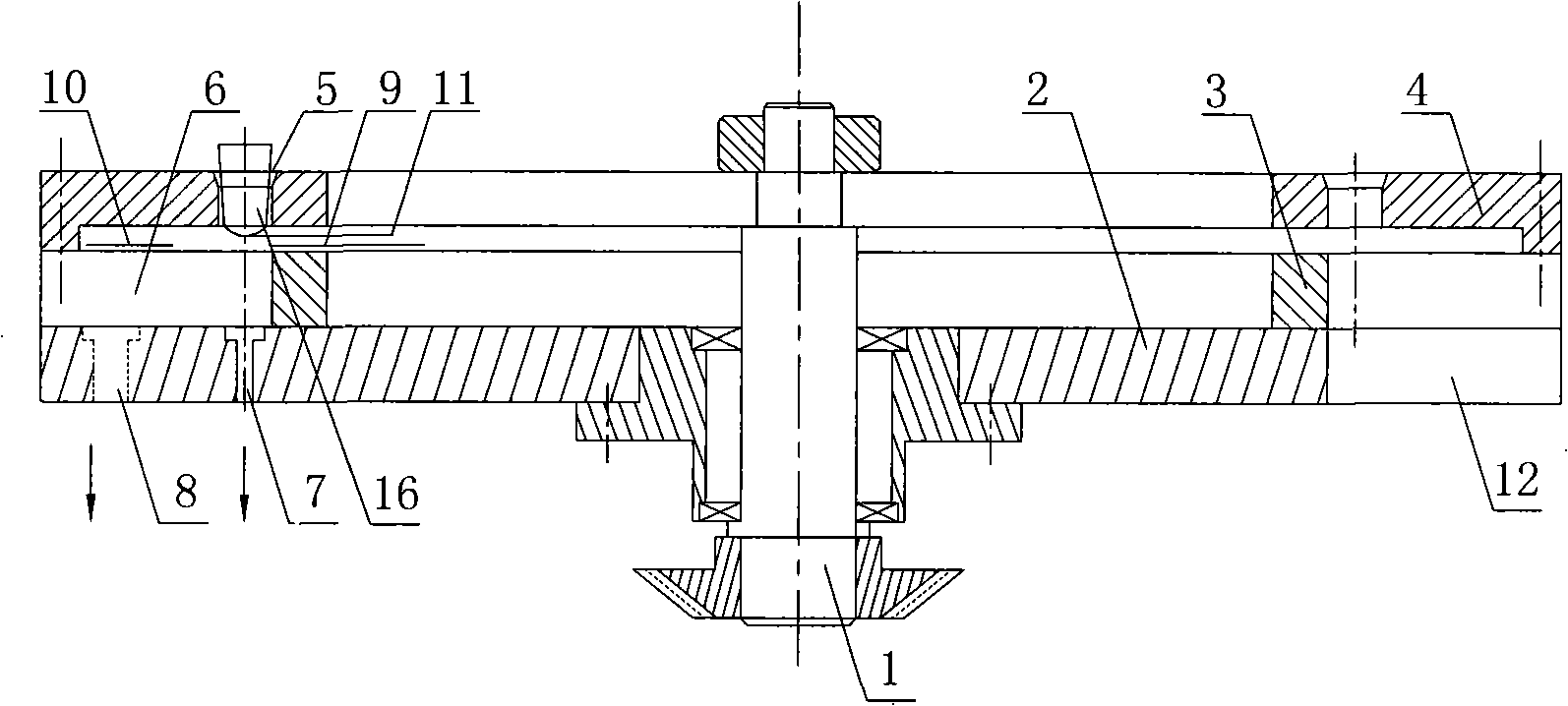

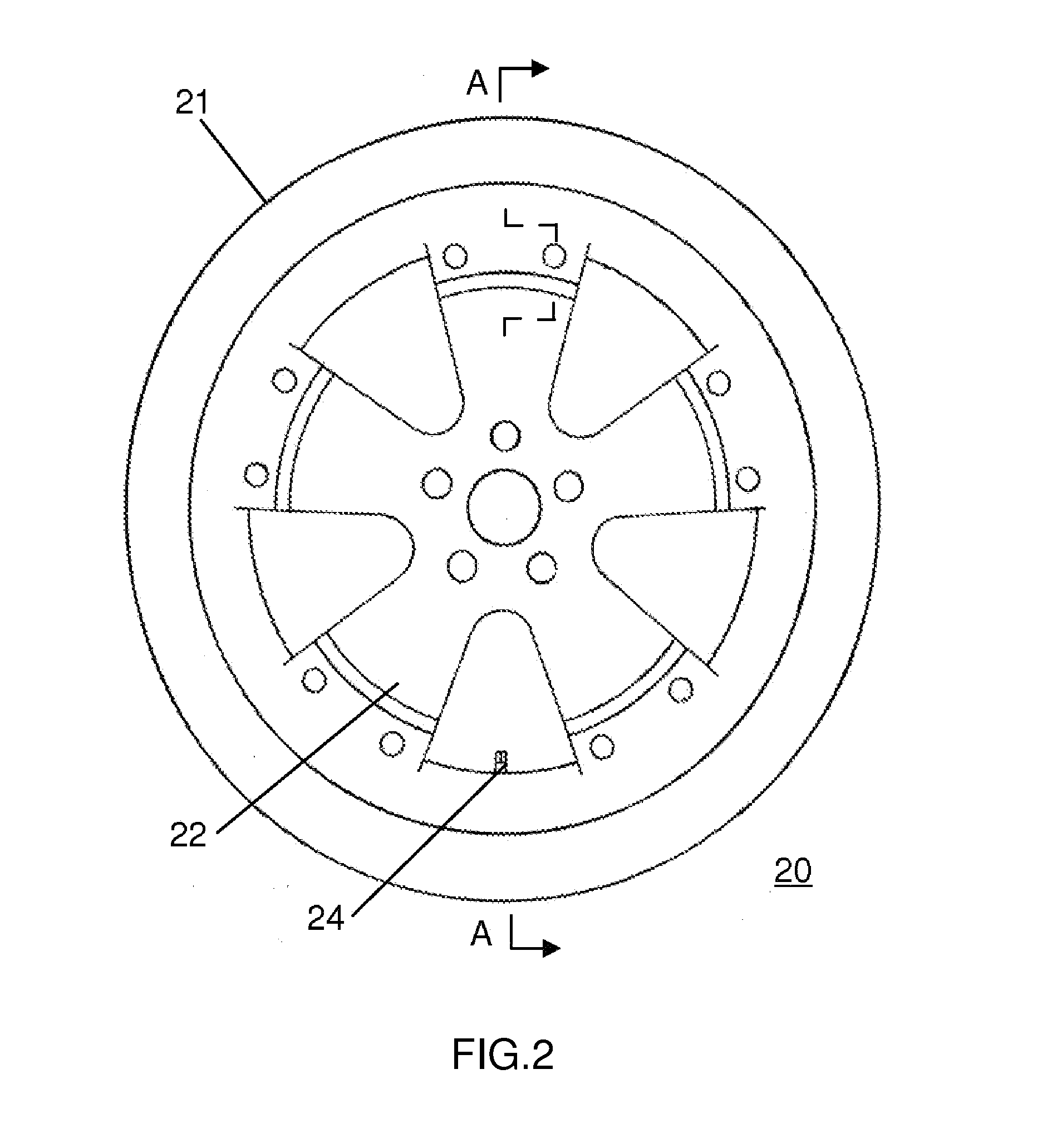

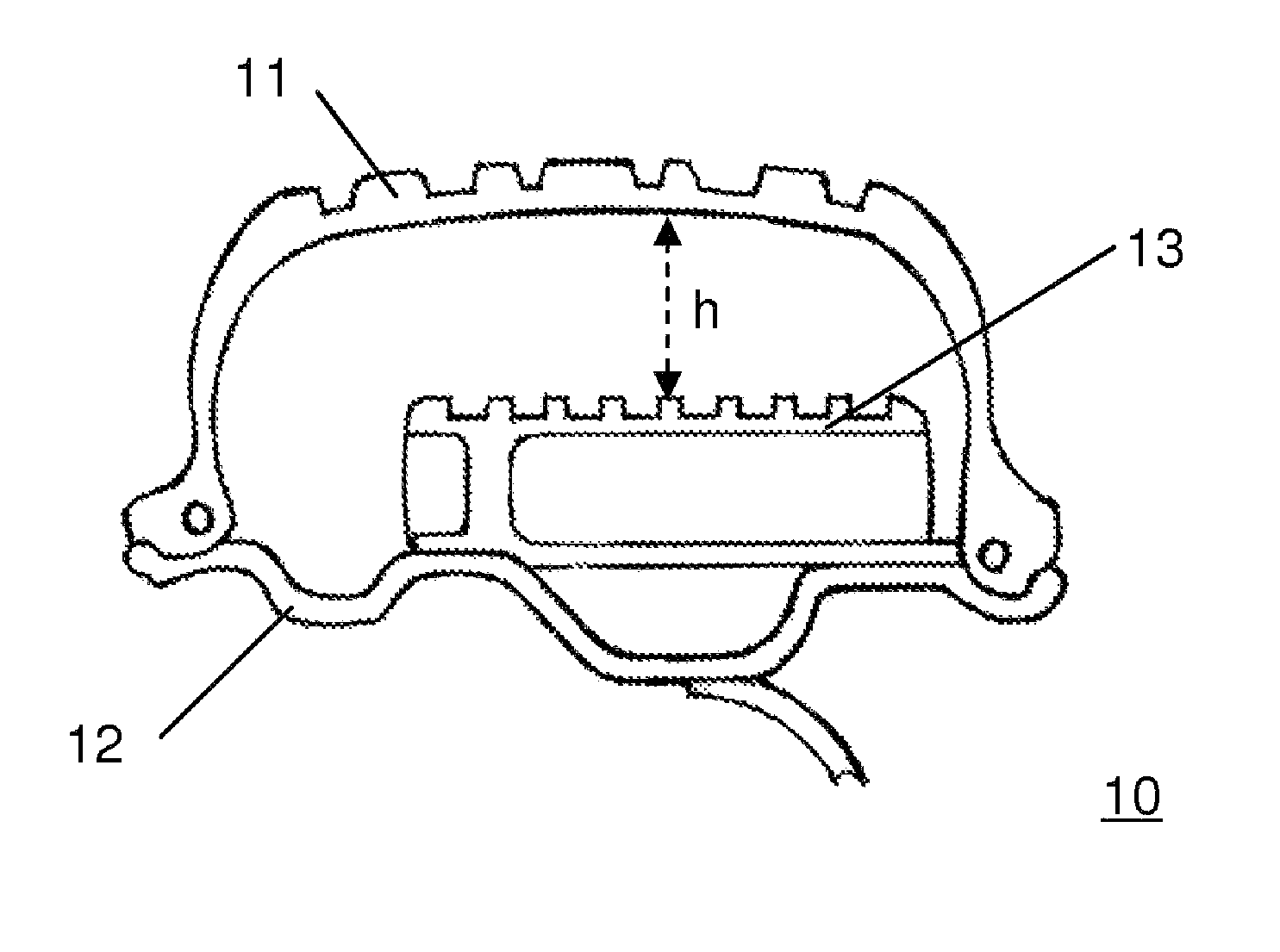

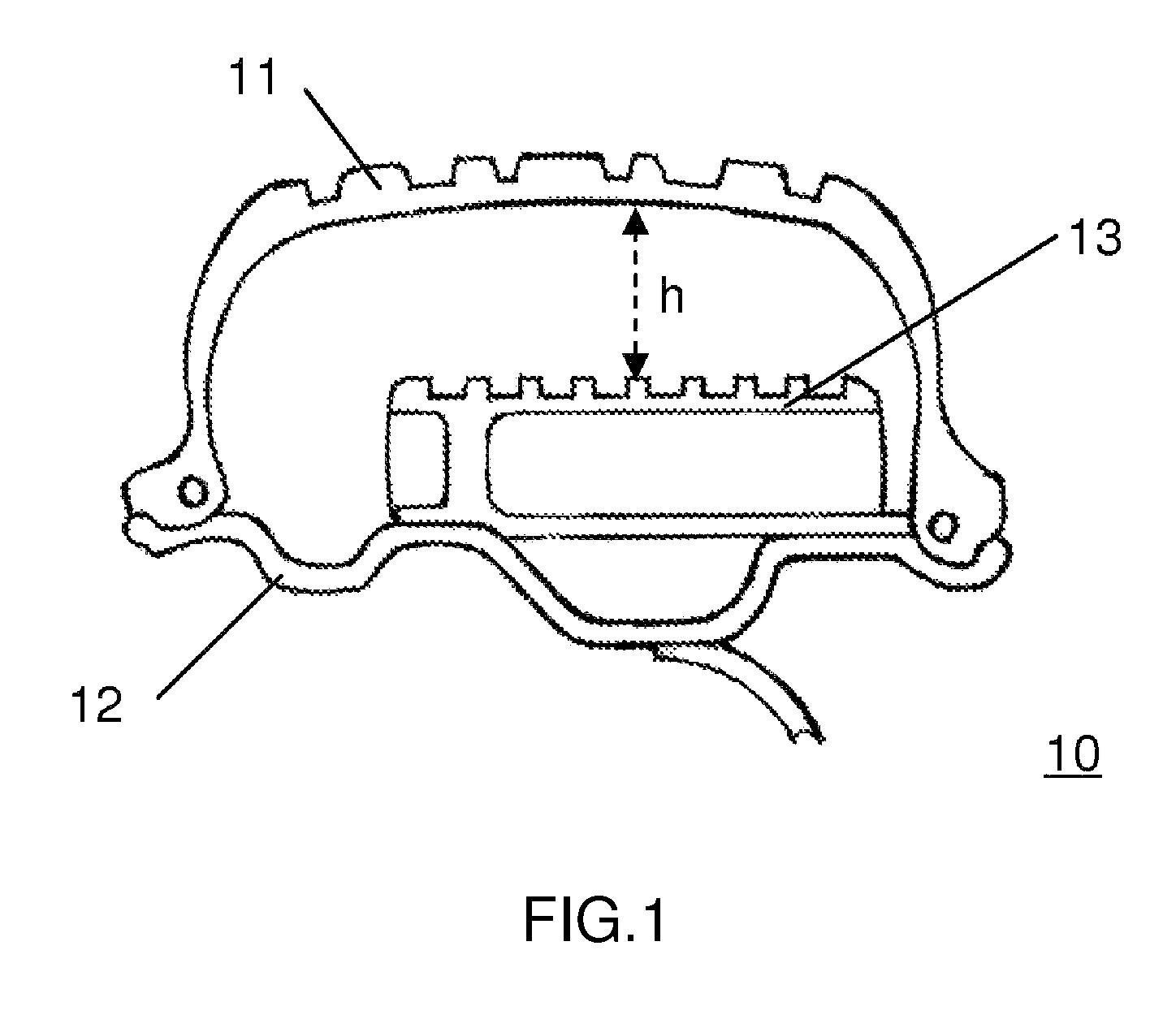

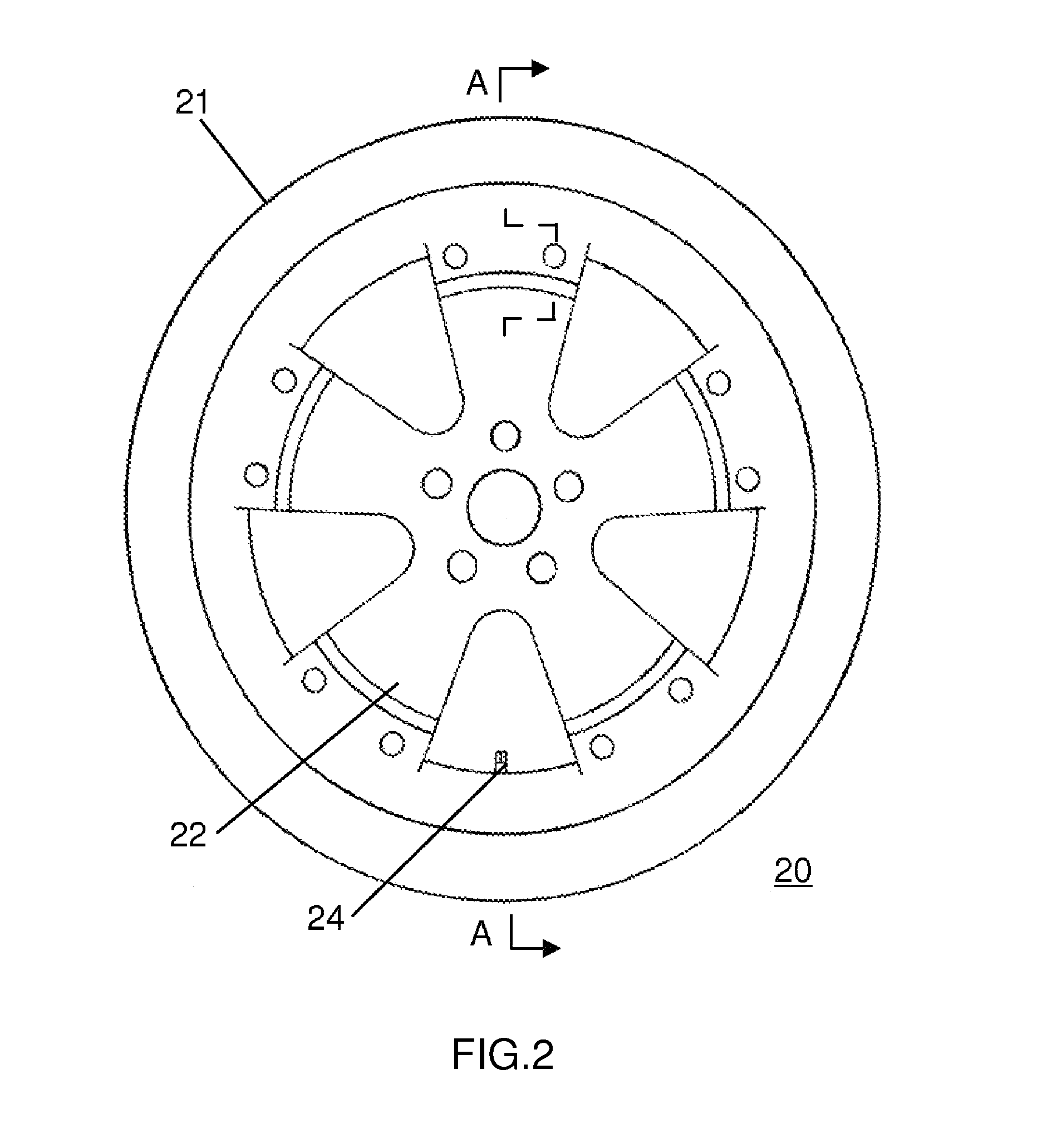

Burst-proof safety tyre of vehicle

InactiveUS20120112520A1Prevent change of directionSize of supportTyre partsAuxillary traction increasing equipmentTweelEngineering

The present invention relates to an explosion-proof security tyre for vehicles. The tyre includes an outer tyre, a split rim, a L-shaped sealing ring, a combined support loop and a valve core. The combined support loop includes a plurality layers of support rings they are sleeved by layer on layer and fixed with the rim. The size of the tyre can increased by the combined support loop so as to furthest shorten the distance between the inner wall of the outer tyre and the outer wall of the combined support loop at a normal pressure of tyre. At the moment that the tyre is burst, the combined support loop can support the outer tyre quickly and effectively, and control the change of acting radius of the tyre in a minimum range so as to ensure the basic performance of the tyre and to prevent accidents caused by sudden control loss of running direction and avoid potential security risks. Moreover, the split rim is benefit for mounting the combined support loop by layering, and is easy to be assembled and disassembled so that the tyre can be maintained and replaced by normal tools.

Owner:WU XIAOYIN +1

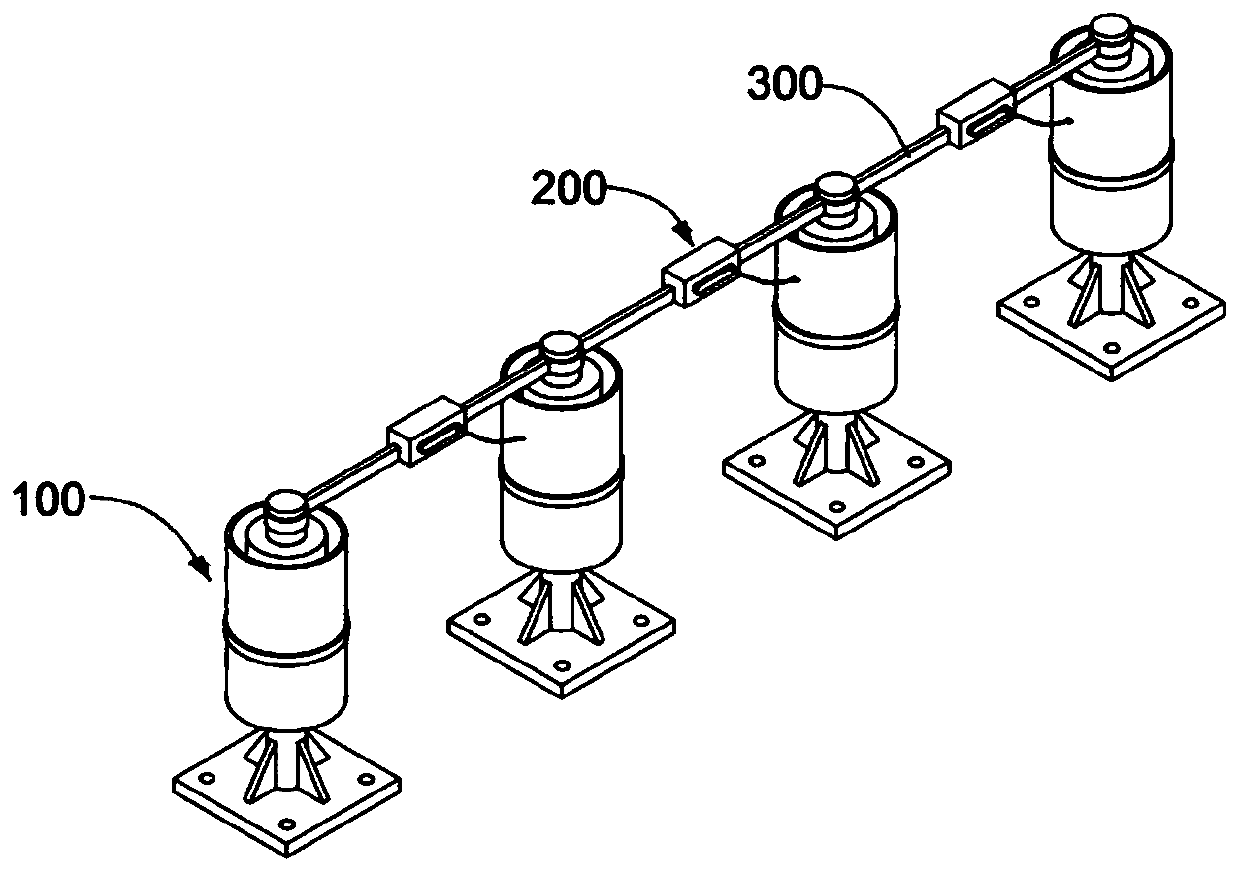

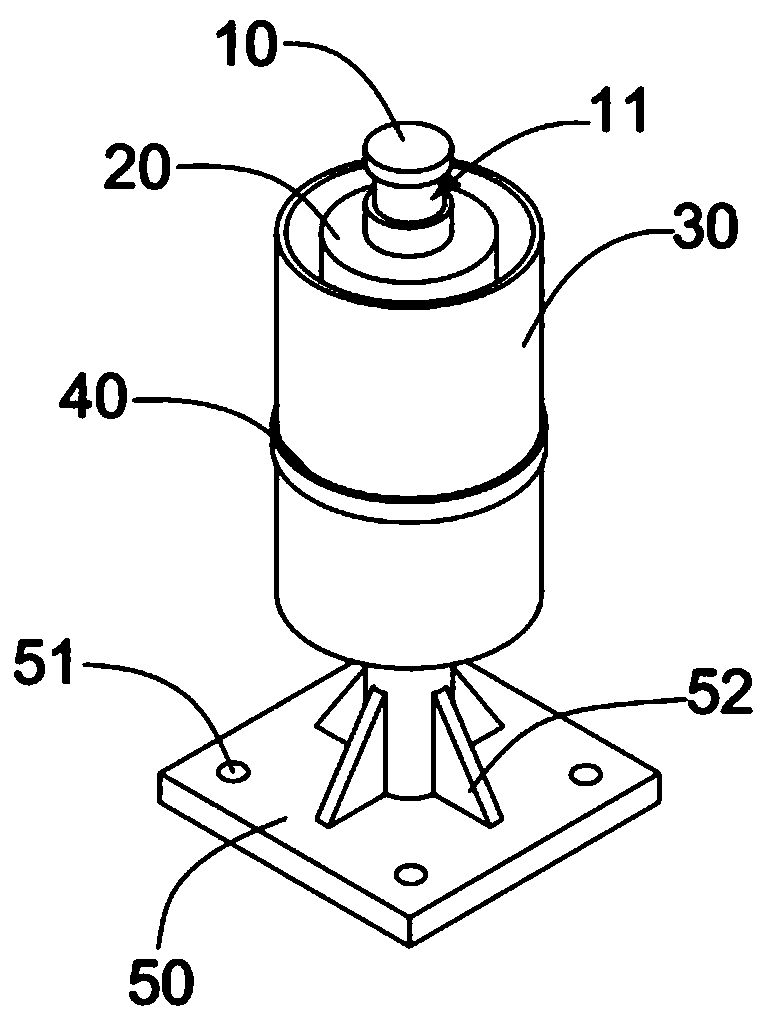

Flexible anti-collision guardrail system of sea-crossing bridge

ActiveCN110258327AEvenly spacedImprove protection securityBridge structural detailsCross bridgeEngineering

The invention discloses a flexible anti-collision guardrail system of a sea-crossing bridge, and belongs to the technical field of road safety protection. The flexible anti-collision guardrail system of the sea-crossing bridge comprises protection assemblies arranged in a whole column and a first handrail used for connecting and fixing the protection assemblies, wherein air sac ejection assemblies are installed on the first handrail, each protection assembly comprises a cylinder body, an inner box which can rotate around each cylinder body is connected with each cylinder body in sleeving mode, an outer box is arranged around the exterior of each inner box, the box wall of each outer box is connected with each air sac ejection assembly through a rope body, and the air sac ejection assemblies are started for ejecting air sacs by rotating the outer boxes. The flexible anti-collision guardrail system of the sea-crossing bridge can achieve a buffer function when a vehicle strikes a guardrail, achieves elastic collision between the vehicle and the bridge guardrail, and effectively reduces harm and loss which are caused by rigid collision to the vehicle and passengers.

Owner:ZHEJIANG OCEAN UNIV

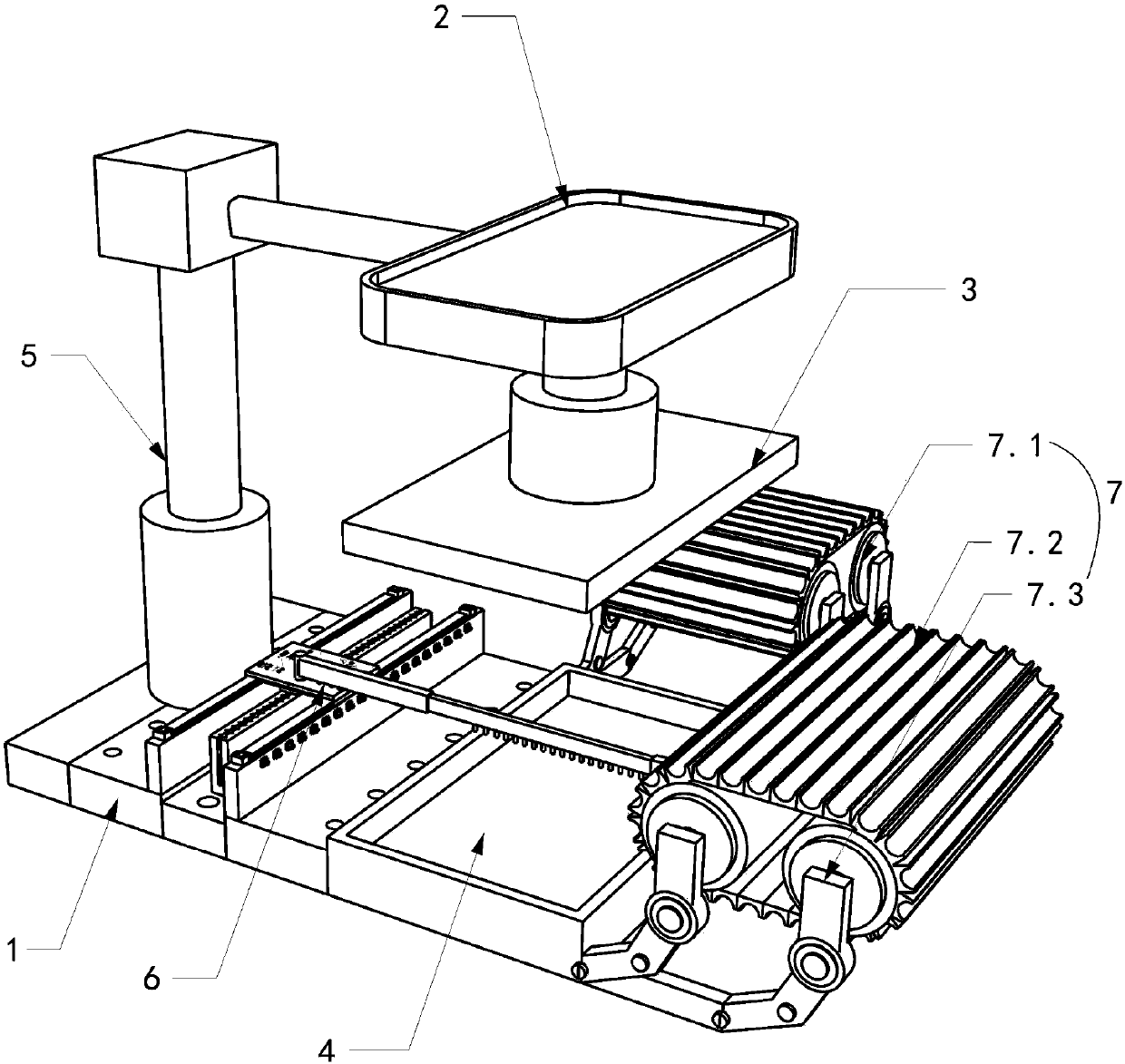

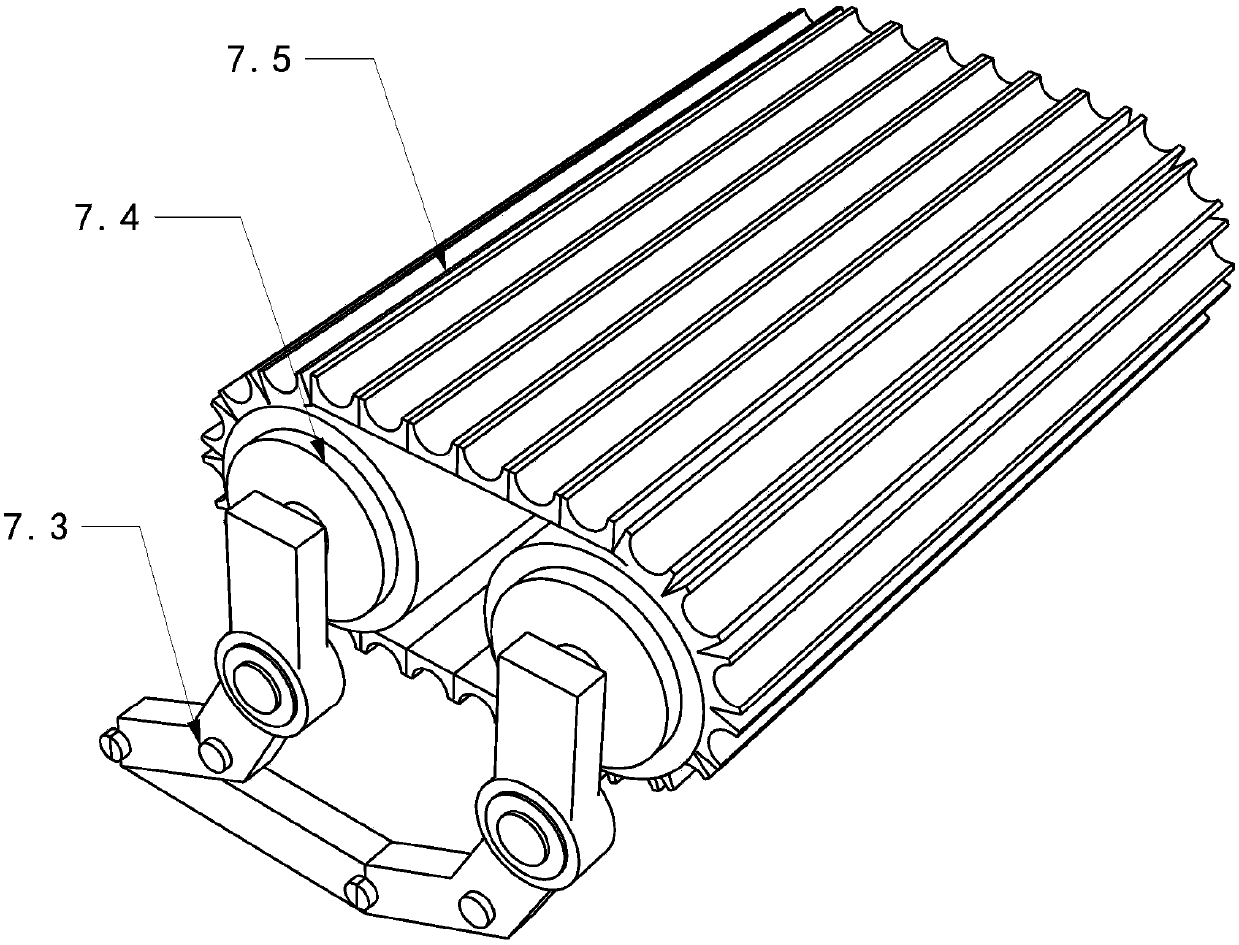

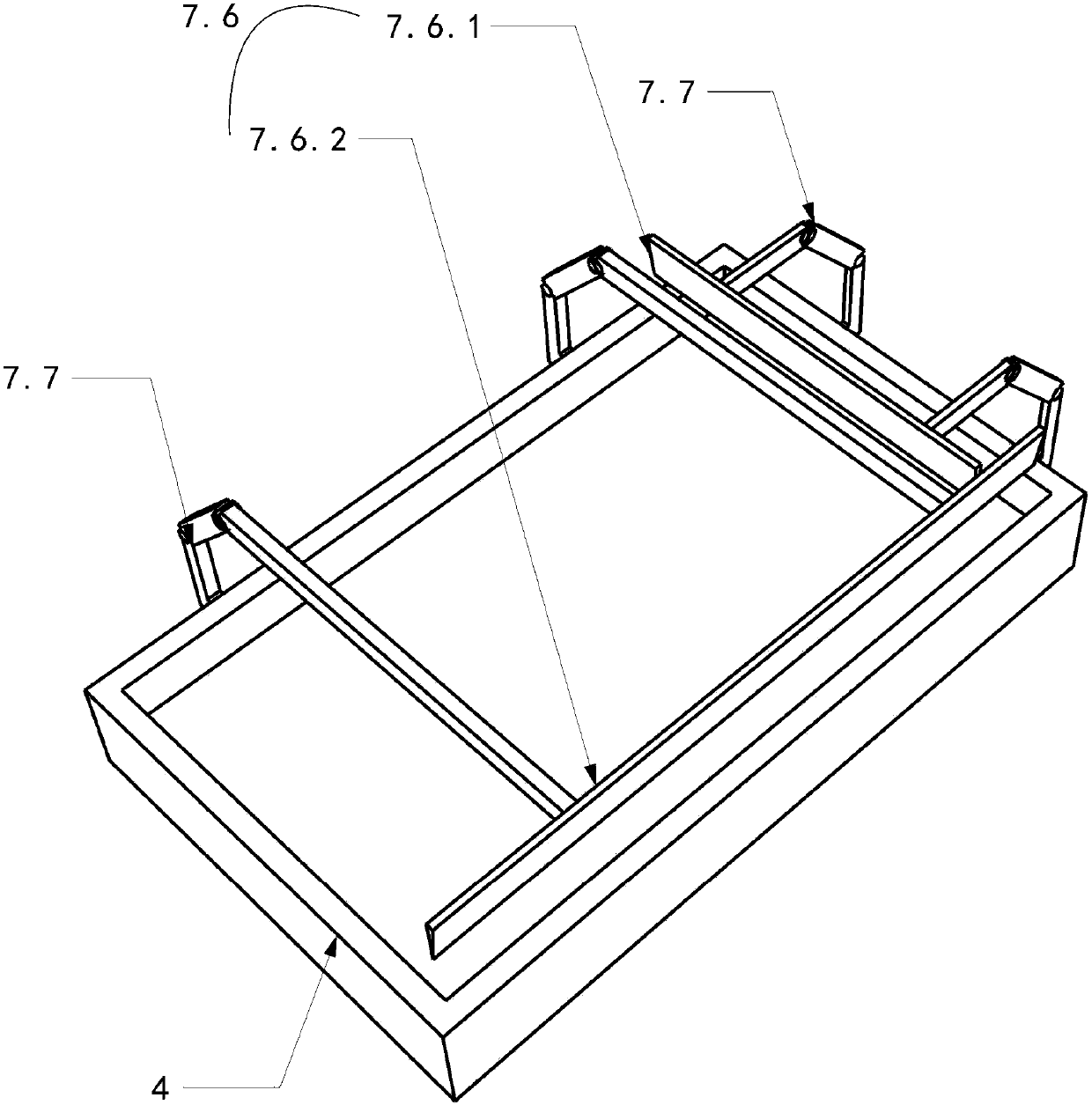

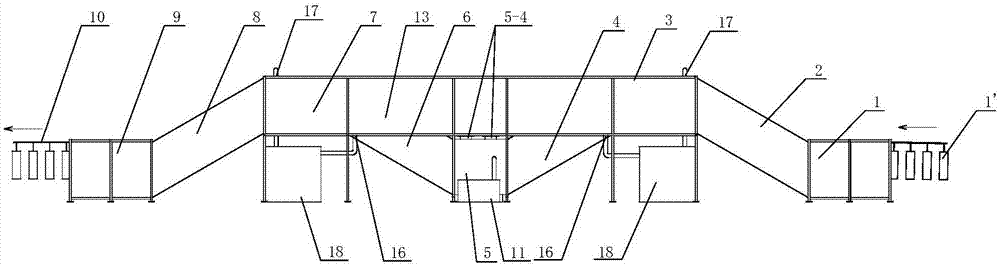

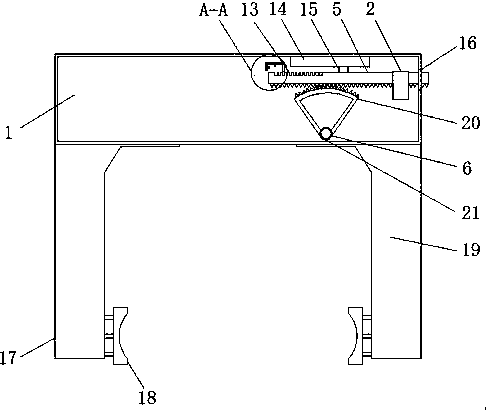

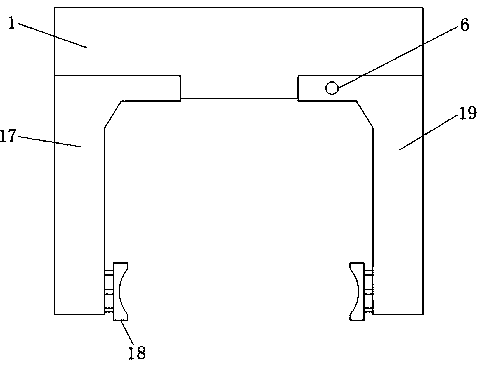

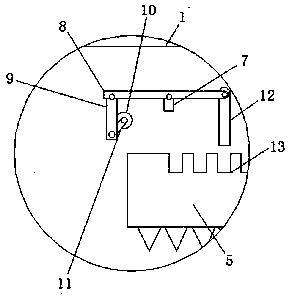

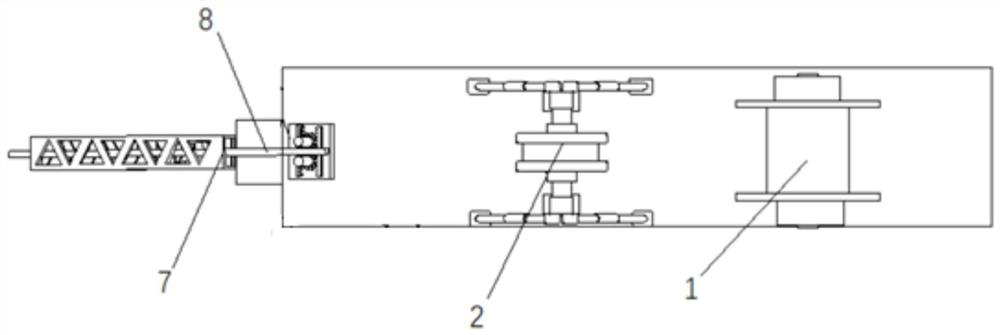

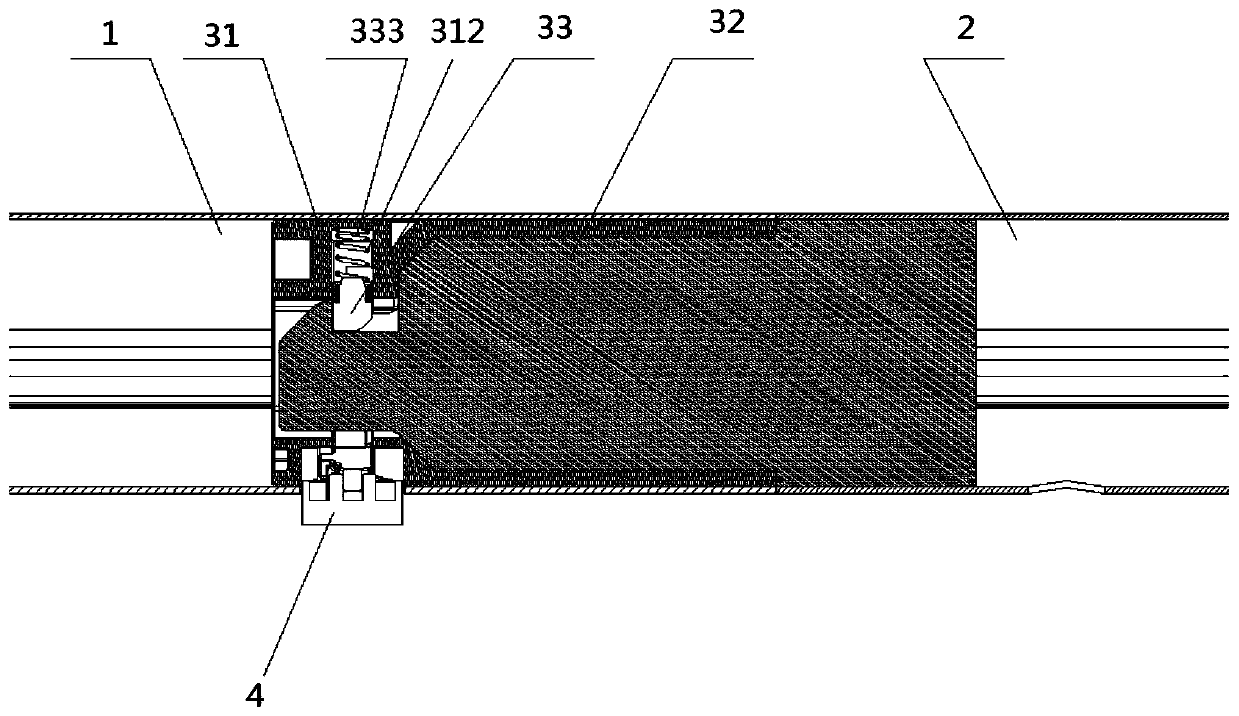

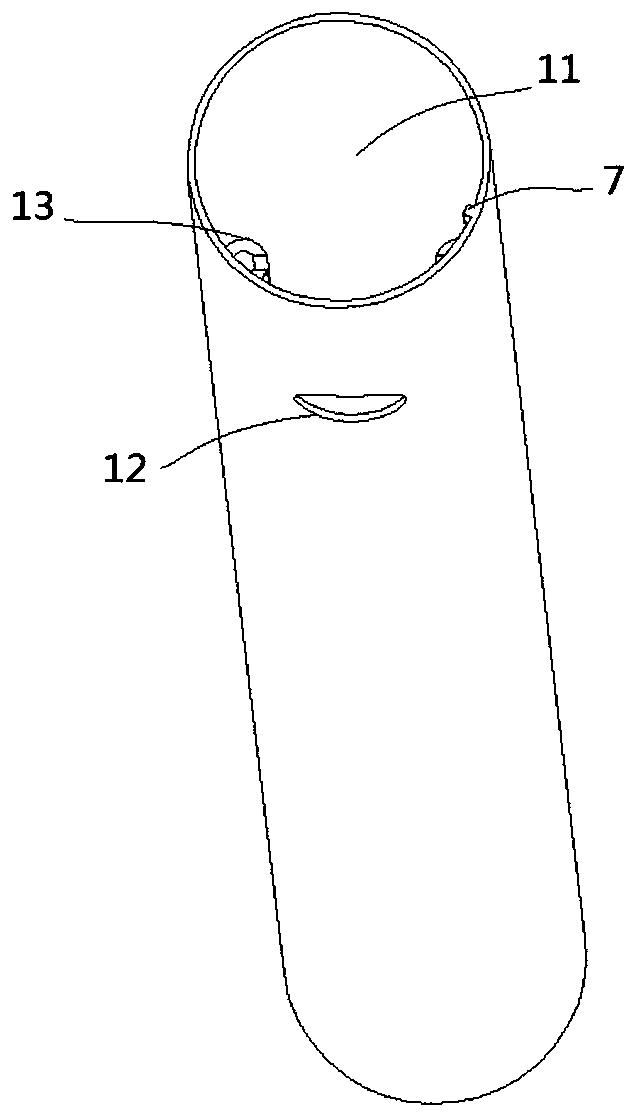

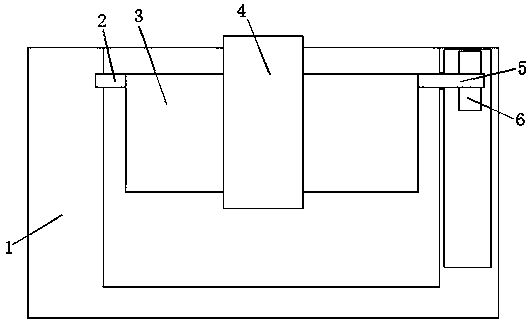

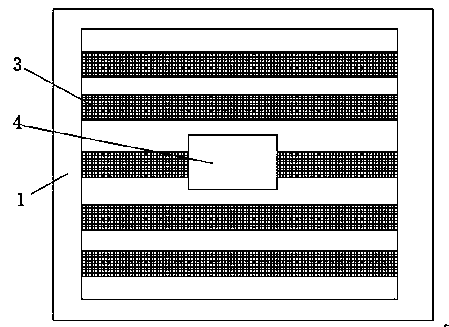

Hot-pressing equipment for producing long-fiber high-strength fiber plate

InactiveCN107813401AImprove mechanical propertiesHigh precisionDomestic articlesFlat articlesMechanical stretchingFiber

The invention relates to the technical field of hot press equipment, and specifically discloses a hot press equipment for producing long-fiber high-strength fiberboards, including a machine base (1), a fuselage (2), a mechanical telescopic press plate (3), and a mechanical The pressure groove (4) matched with the telescopic pressure plate (3), the fuselage (2) is fixed above the base (1), and the mechanical telescopic pressure plate (3) is connected with the fuselage (2) through a hydraulic rod (5) , the press groove (4) is opened on the support (1), the described press groove (4) is rectangular, the groove depth of the press groove (4) is 5mm-10mm, and also includes an adhesive supply mechanism that cooperates with each other (6), and a feeding mechanism (7), the adhesive supply mechanism (6) is installed on the side of the pressure groove (4), and the feeding mechanism (7) is connected to the side of the pressure groove (4). The device can arrange coconut fiber raw materials in multiple directions, so that the mutual force is greatly enhanced, and the mechanical properties of the coconut fiber board are improved.

Owner:内江市旭日环境科技有限公司

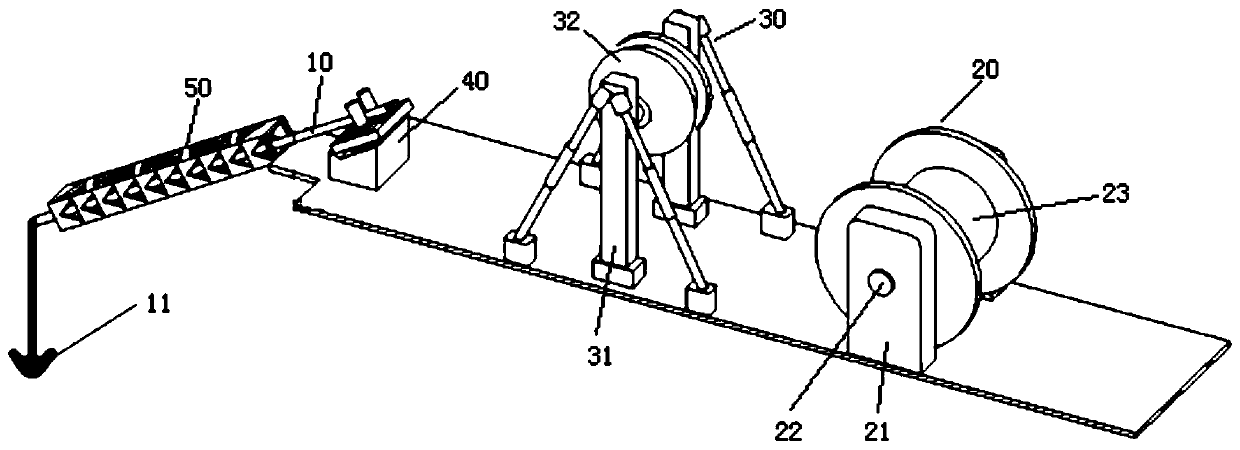

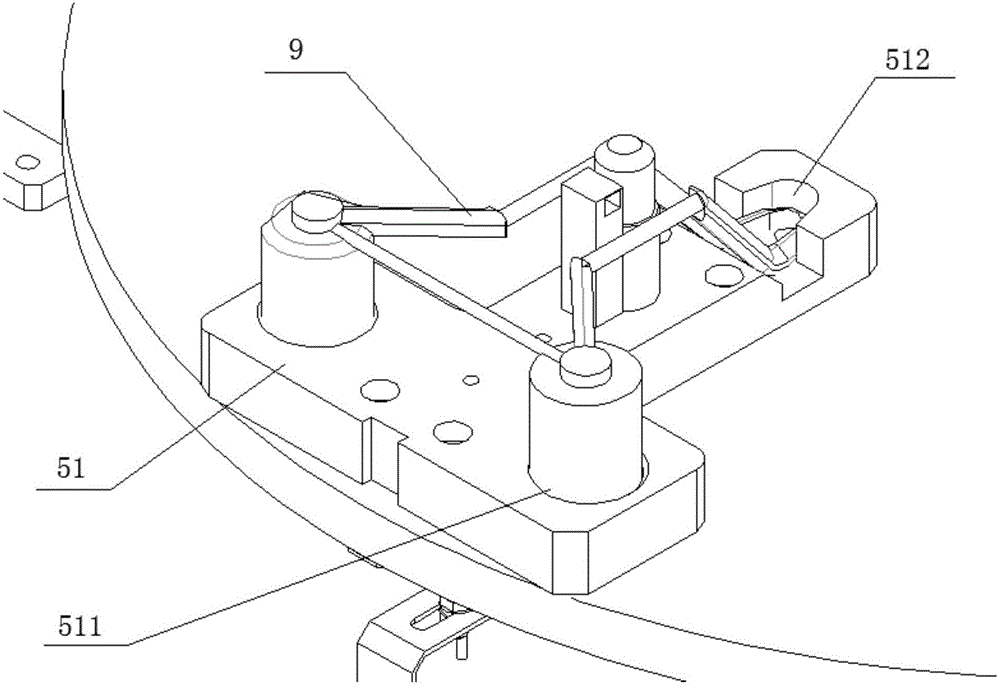

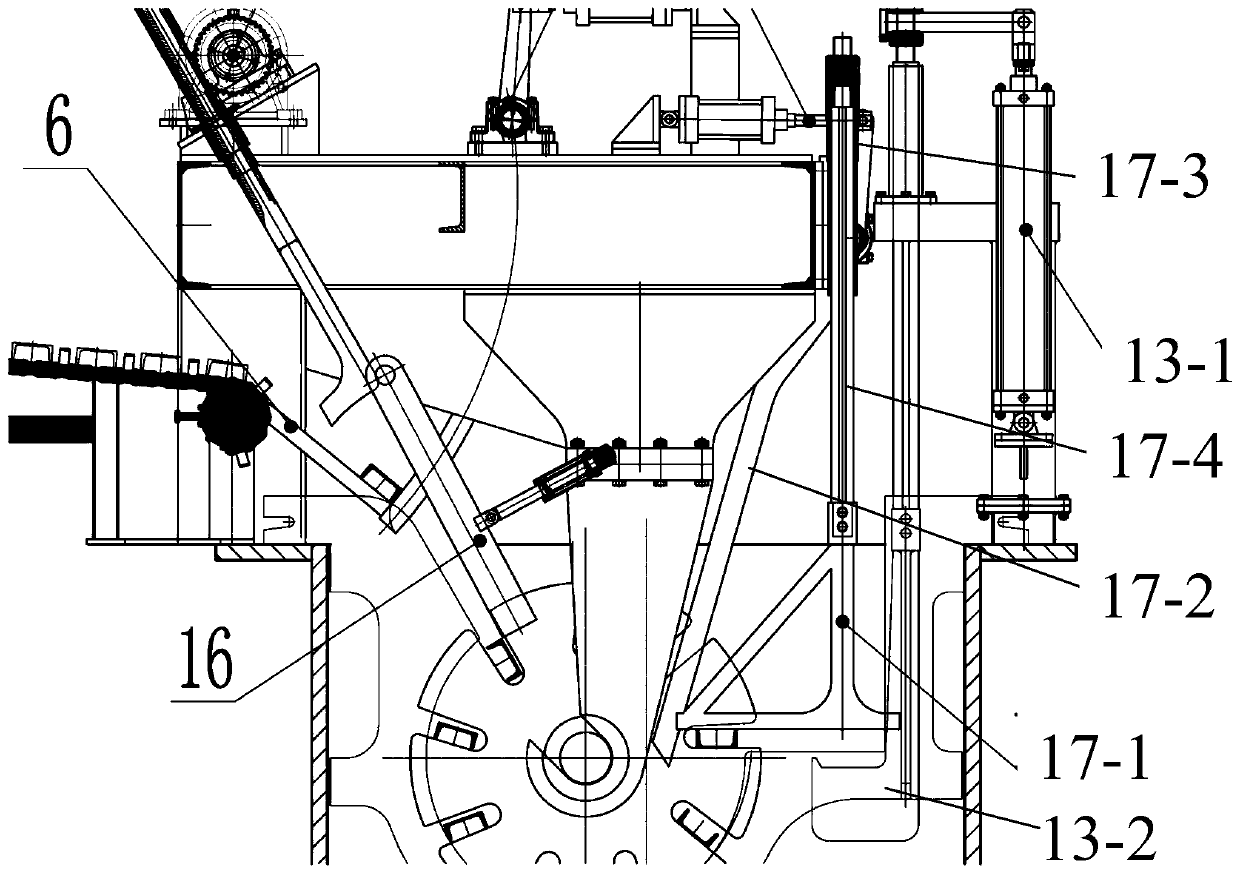

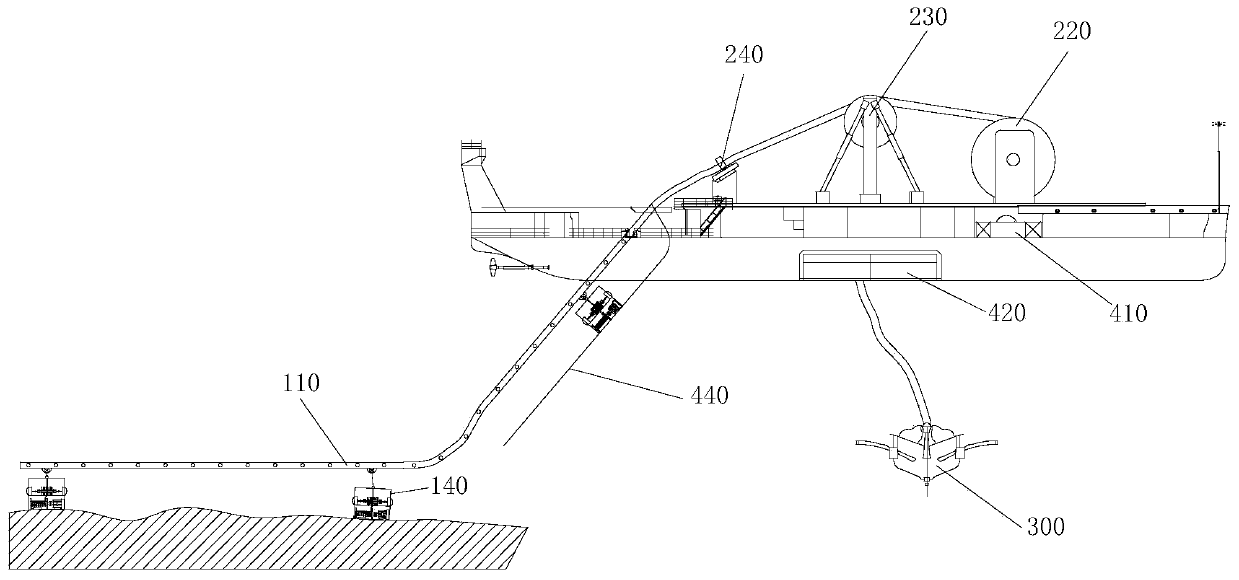

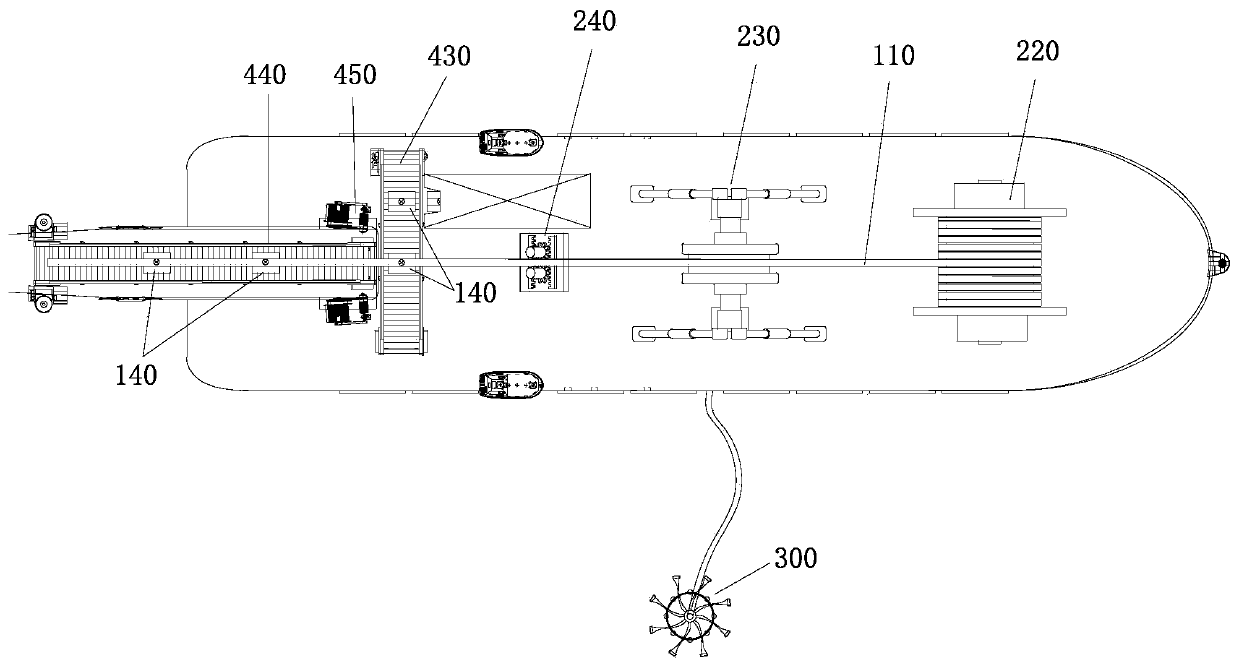

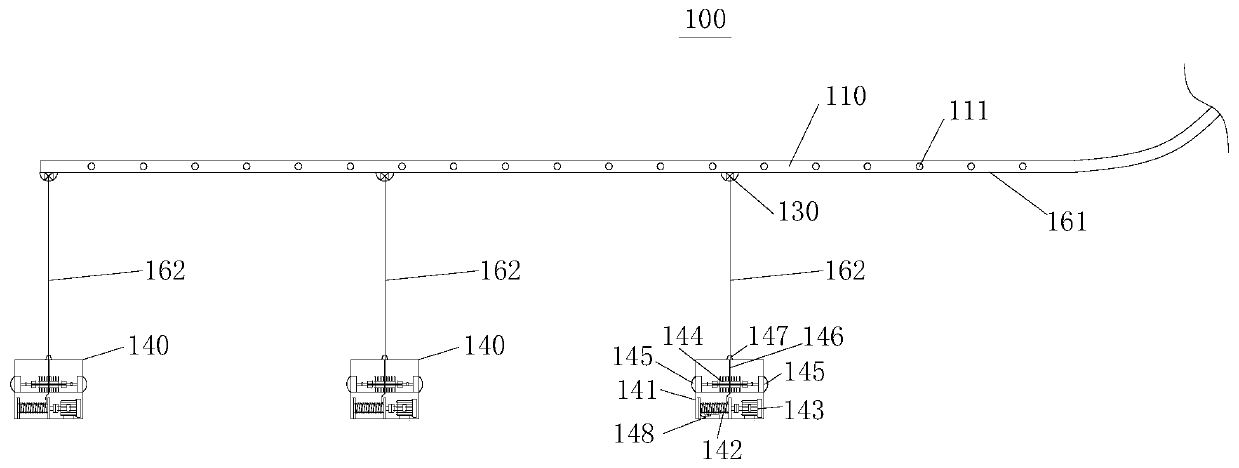

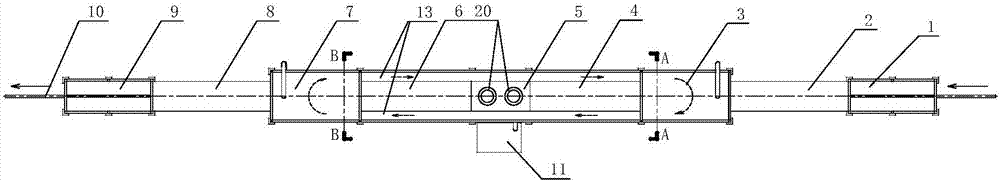

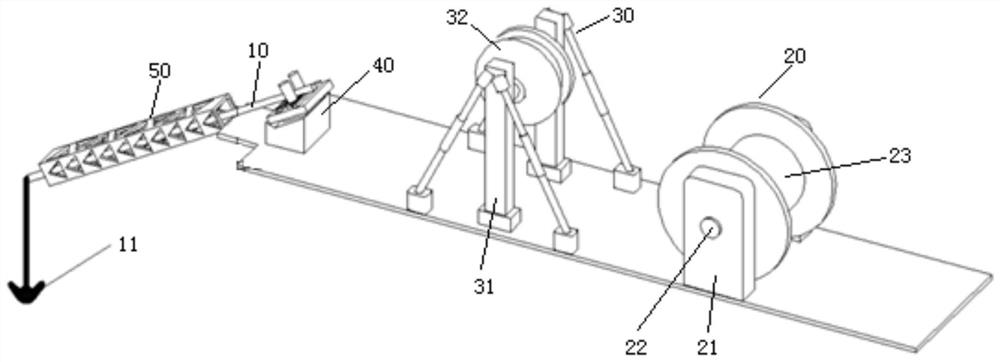

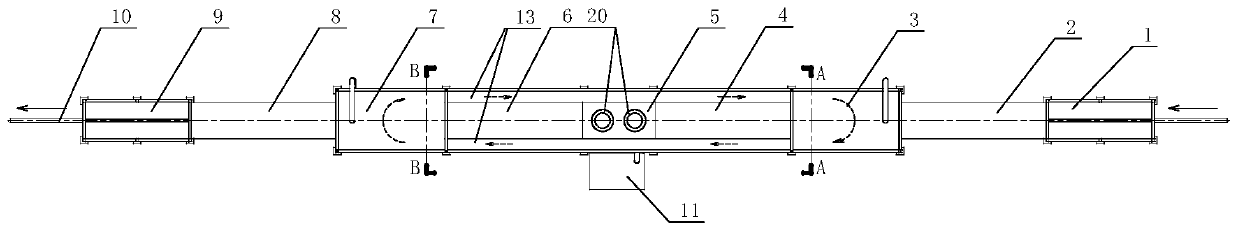

Laying device for rubber hose

ActiveCN110886903AAlleviate the shaking tendencyImprove job stabilityPipe laying and repairElectric machineryFriction drive

The invention relates to a laying device for a rubber hose. The device comprises the rubber hose, a rolling device, a corrector, a laying power device and a hose laying rack. The roller device is provided with a first motor; the corrector comprises a support mounted on a ship and a pulley installed on the support; the laying power device comprises a fixing table mounted on the ship and a base mounting on the fixing table, and the base is provided with a fixed rack, a movable rack, a gear and a rail; one end of the hose laying rack is installed on the ship, and the other end of the hose layingrack inclines downwards and is suspended on the water surface; and one end of the rubber hose winds the roller device, and the other end of the rubber hose bypasses the pulley of the corrector, penetrates through the position between two laying rollers of the laying power device, penetrates through the hose laying rack and enters water. According to the laying device for the rubber hose, by usinga method for laying the rollers for friction transmission of hose laying, the comprehensive conditions that the transmission performance is high, the efficiency is high, and the hose and an opening can be conveyed in the accurate direction are achieved.

Owner:WUHAN UNIV OF TECH

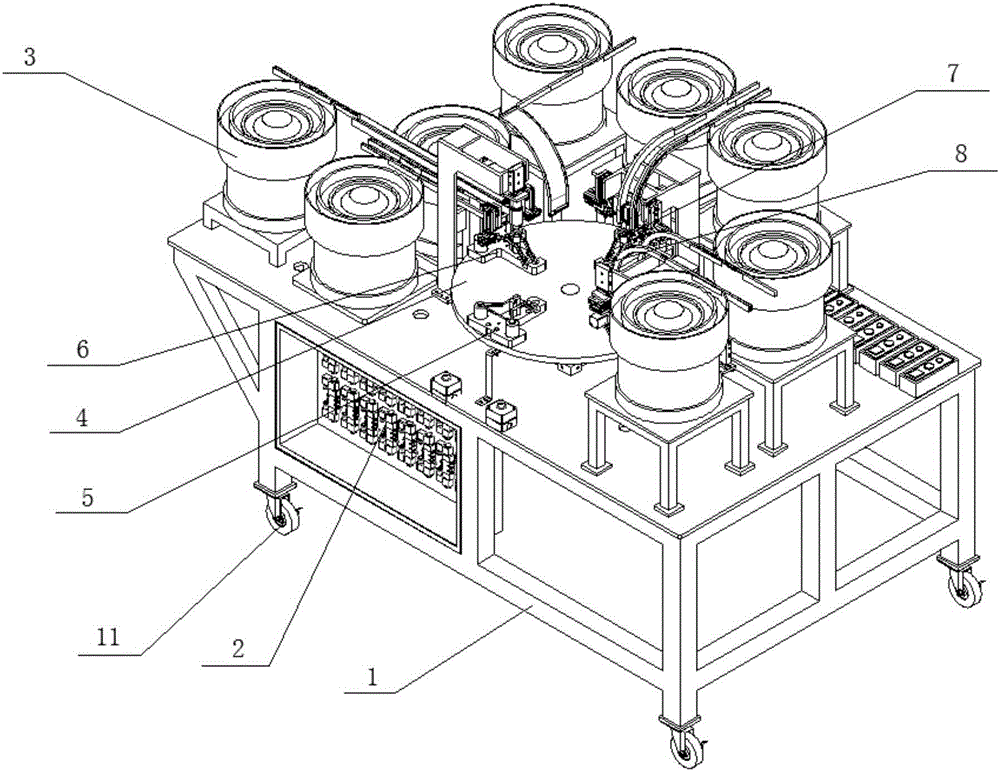

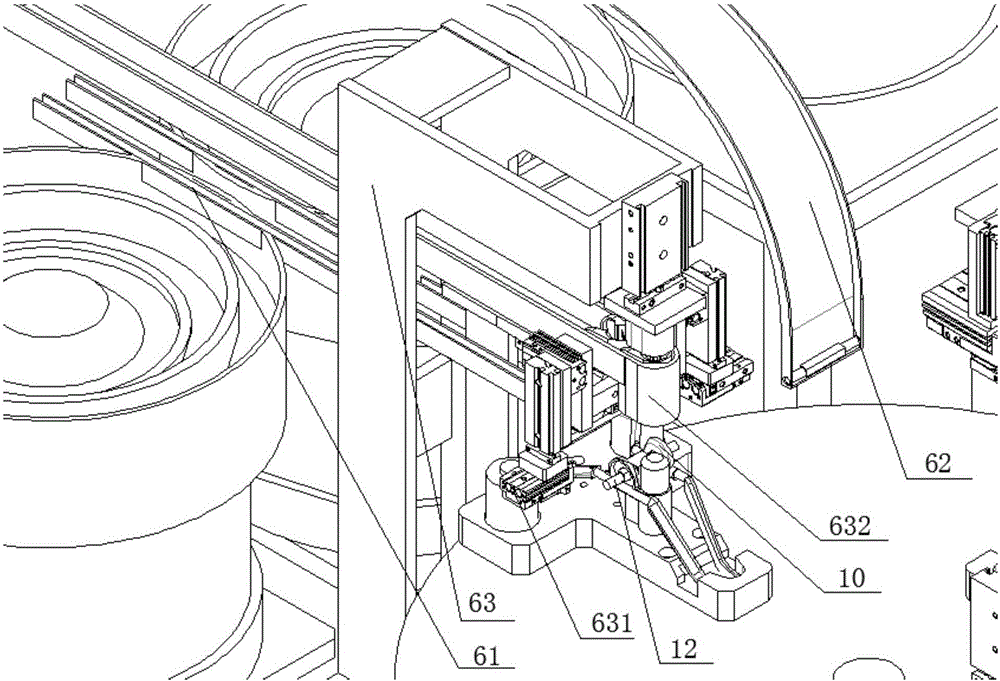

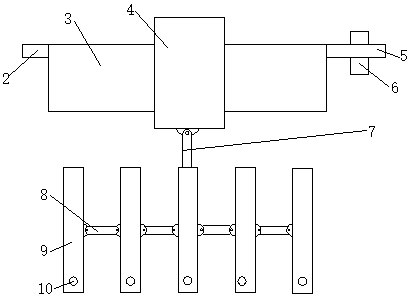

Automatic assembling device for bicycle saddle

The invention provides an automatic assembling device for a bicycle saddle. The automatic assembling device comprises a base, a PLC control cabinet, a feed vibrator, a first station mechanism, a second station mechanism, a third station mechanism and a fourth station mechanism, wherein the first station mechanism, the second station mechanism, the third station mechanism and the fourth station mechanism are arranged in a line production manner. The first station mechanism is used for connecting a saddle frame in a clamping manner and fixing the saddle frame. The second station mechanism is used for automatically installing an inner clamping pad and a square bolt. The second station mechanism comprises a grabbing cylinder, a first conveying rail used for conveying the inner clamping pad, and a second conveying rail used for conveying the square bolt. The third station mechanism is used for automatically installing an outer clamping pad and comprises a material clamping cylinder and a third conveying rail used for conveying the outer clamping pad. The fourth station mechanism is used for installing an outer hexagonal nut and comprises a push cylinder, a fourth conveying rail used for conveying the outer hexagonal nut, and a motor. The automatic assembling device has the beneficial effects that automatic bicycle saddle assembling can be achieved by controlling operation of all stations through a PLC, time and labor are saved, and the assembling efficiency is improved.

Owner:TIANJIN RENYIHE AUTOMATION TECH

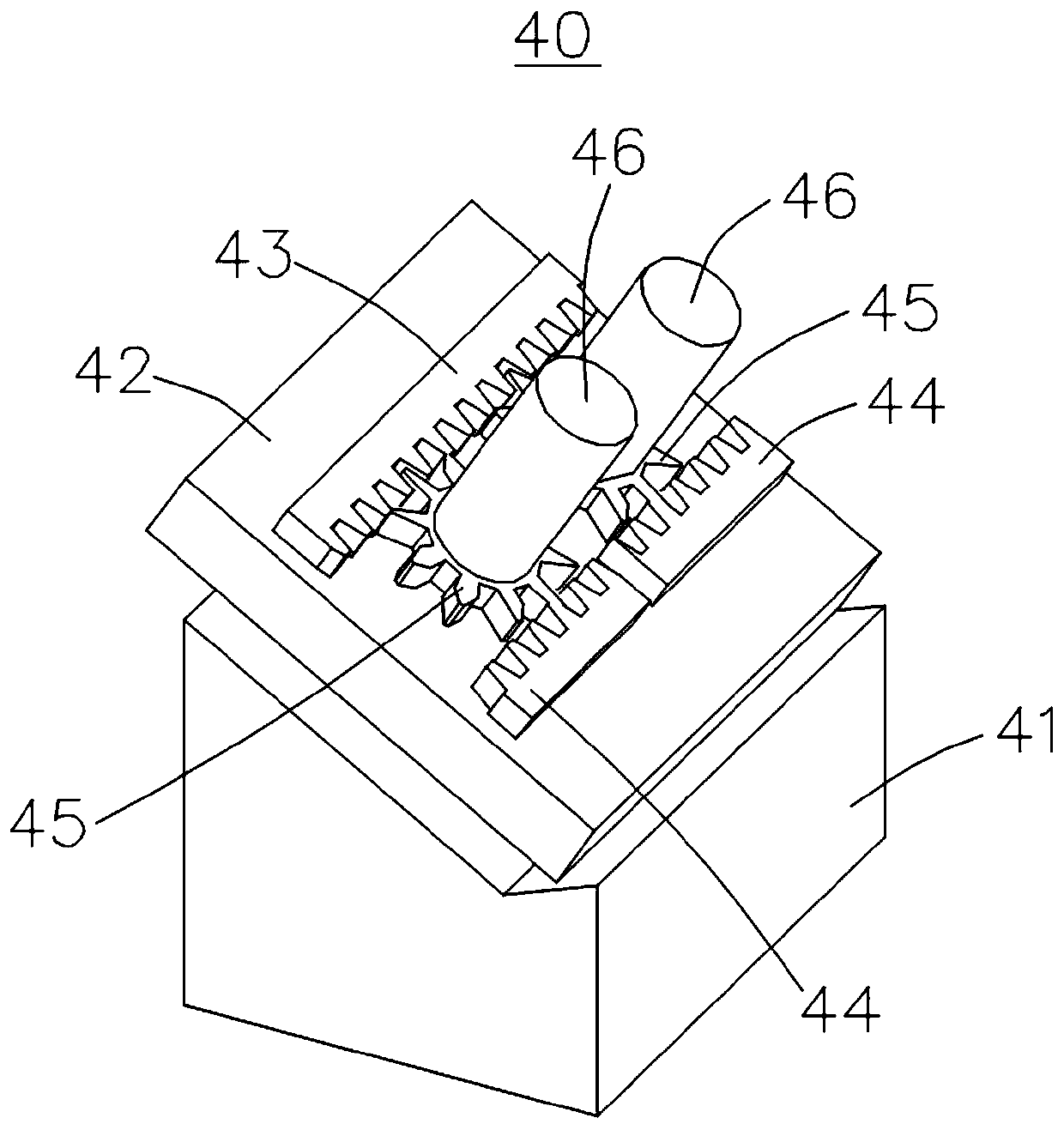

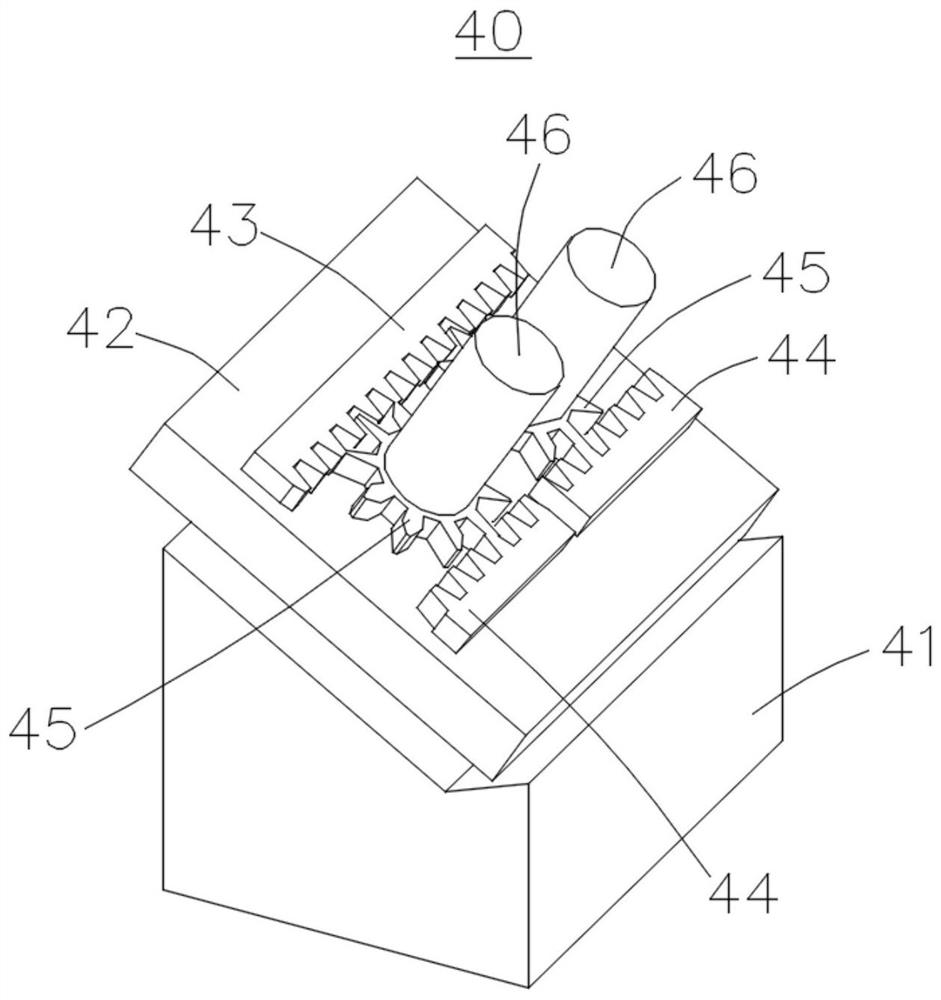

Automatic channel steel galvanizing device

PendingCN110359000AGuaranteed normal slidingSmooth slidingHot-dipping/immersion processesUpper toothOutput device

The invention discloses an automatic channel steel galvanizing device. The automatic channel steel galvanizing device comprises an input device, a zinc pot and an output device, wherein the input device feeds channel steel into the zinc pot, the output device feeds the channel steel galvanized in the zinc pot into the next galvanizing process, a guide rail and a rotatable toothed disc are arrangedin the zinc pot, a plurality of teeth are arranged in the circumferential direction of the toothed disc, and a toothed disc groove capable of containing the channel steel is formed between every twoadjacent teeth; one side close to the input device is provided with a feeding guiding and adjusting mechanism which comprises a guide plate and an adjusting mechanism; one end of the guide plate is ahinged end and the other end of the guide plate extends to an inlet of the toothed disc groove closest to the input device; and the adjusting mechanism is connected with the guide plate. The gap between the guide plate and a sliding bar can be adjusted according to different types of channel steel, the channel steel is prevented from overturning or being pricked to the upper teeth of the toothed disc grooves when the channel steel slides downwards, it is guaranteed that the channel steel slides downwards along the inclined plane of the sliding bar, and thus the channel steel can be smoothly guided into the toothed disc grooves.

Owner:JIANGSU GUOQIANG ZINC PLATING IND

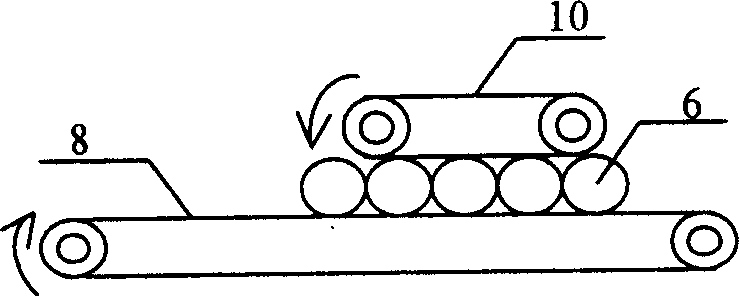

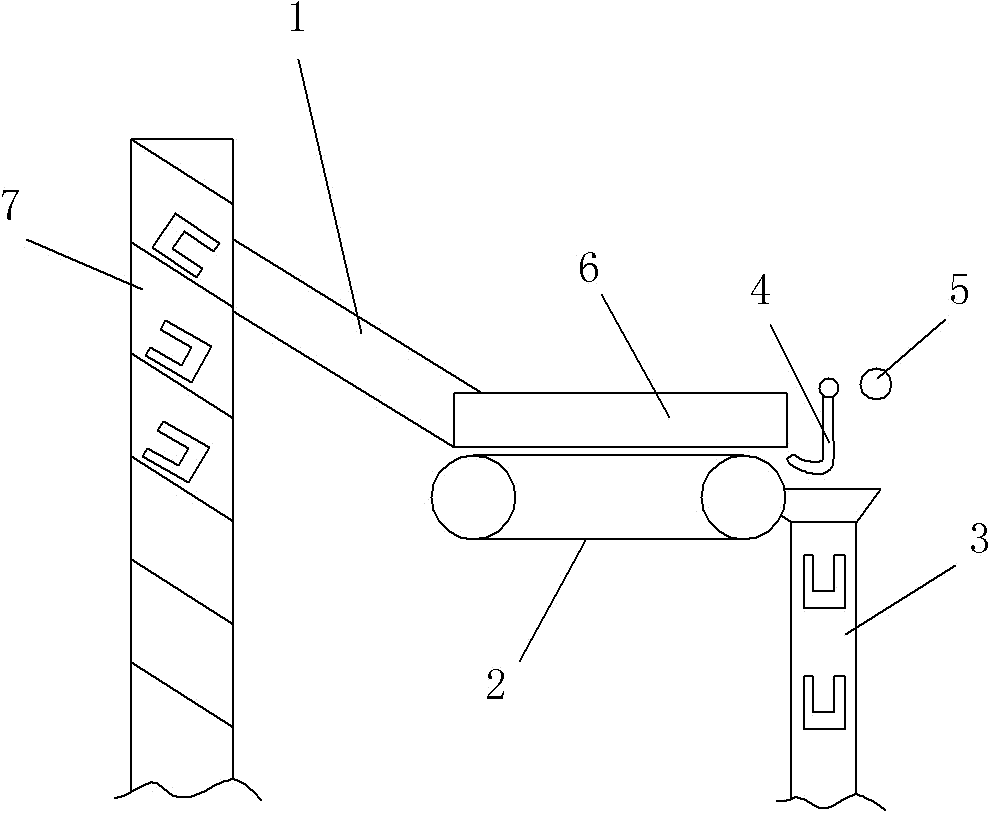

Orientation transmission mechanism for workpiece with end face with hole

InactiveCN103754614APrevent slippingWith guiding functionConveyorsConveyor partsTransmission beltEngineering

The invention discloses a transportation device, and particularly relates to an orientation transmission mechanism for a workpiece with an end face with a hole. The orientation transmission mechanism comprises a feeding chute, a transmission belt and an orientation groove, an outlet of the feeding chute is close to an input end of the transmission belt, the orientation groove is formed in an output end of the transmission belt, a swing hook is arranged above the orientation groove, a bent free end of the swing hook faces the conveying direction of the transmission belt, a stop pin is arranged behind the swing hook and positioned above an opening of the orientation groove, and the stop pin and a suspension point of the swing hook are positioned at the same height. By the aid of the technical scheme, the orientation transmission mechanism for the workpiece with the end face with the hole is simple in structure, and the workpiece can be transmitted in an oriented manner.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

Oil-spill treatment rescue boat based on air-bubble curtain technology

ActiveCN110700214ASteady and continuous bubble plumePoor bubble plume reductionWater cleaningWaterborne vesselsBubble curtainMarine engineering

The invention relates to an oil-spill treatment rescue boat based on an air-bubble curtain technology. The oil-spill treatment rescue boat comprises a dirt separator and a pipelaying device, wherein the dirt separator comprises an air conveying pipe and robe box devices; air holes are formed in the air conveying pipe, a main coaxial cable is arranged on the bottom in the length direction, overcurrent diverters are arranged at intervals, and the bottoms of the overcurrent diverters are provided with electromagnetic relays. The pipelaying device comprises a roller device, a corrector and a laying power device; one end of the air conveying pipe is connected with an air compressor, the other end of the air conveying pipe is wound on the roller device and then wound around the corrector and thelaying power device in sequence; a first transfer belt transfers the rope box devices to the air conveying pipe, and the rope box devices are connected with the air conveying pipe at the junction ofthe first transfer belt and the air conveying pipe; a second transfer belt cooperates with the laying power device to work so as to transfer the rope box devices and the air conveying pipe which havebeen connected into water. According to the oil-spill treatment rescue boat, a pipelaying vessel is integrated with an oil-spill recovery boat, function integration is achieved, and pipelaying, oil coaming and oil recovery can be achieved by the same boat.

Owner:WUHAN UNIV OF TECH

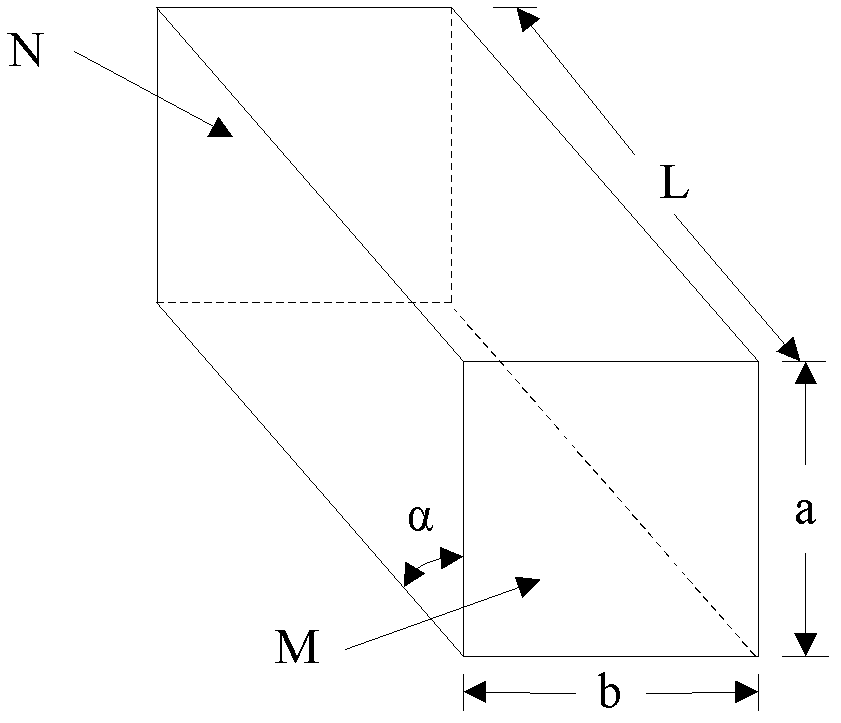

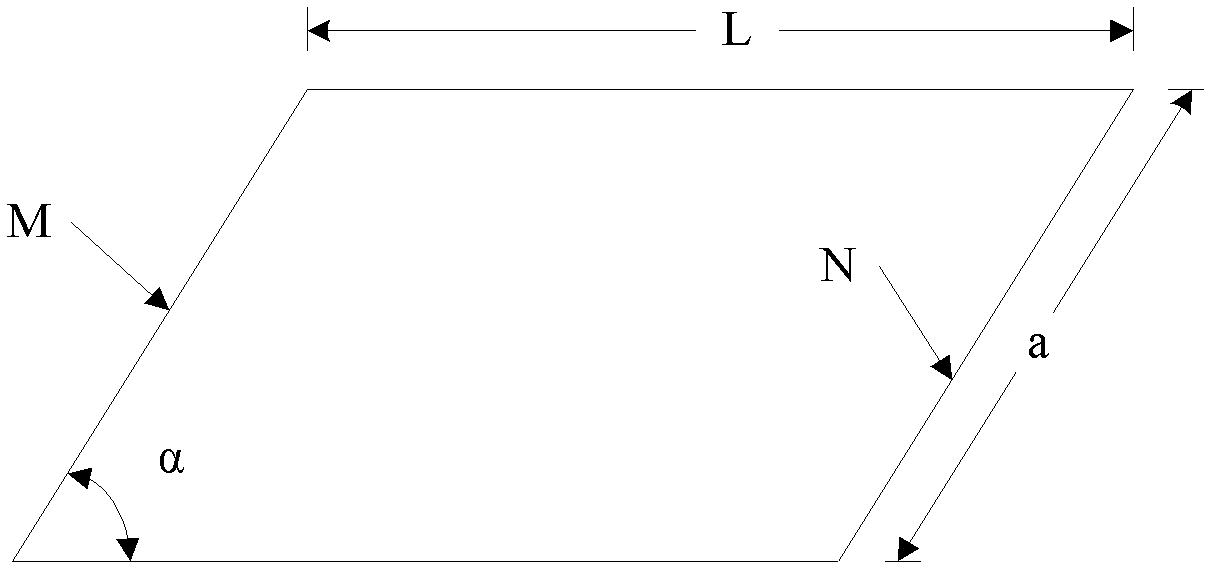

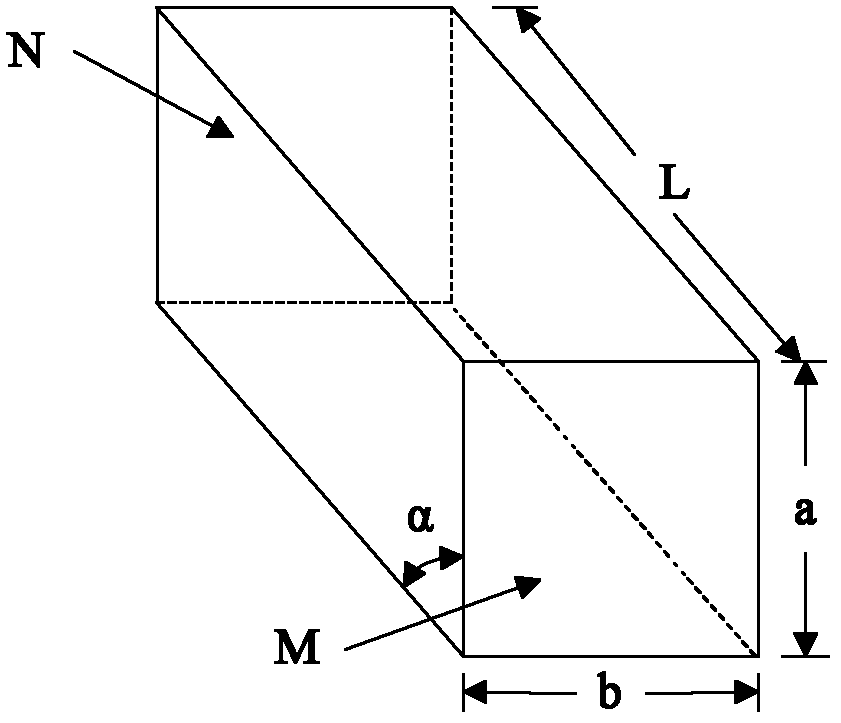

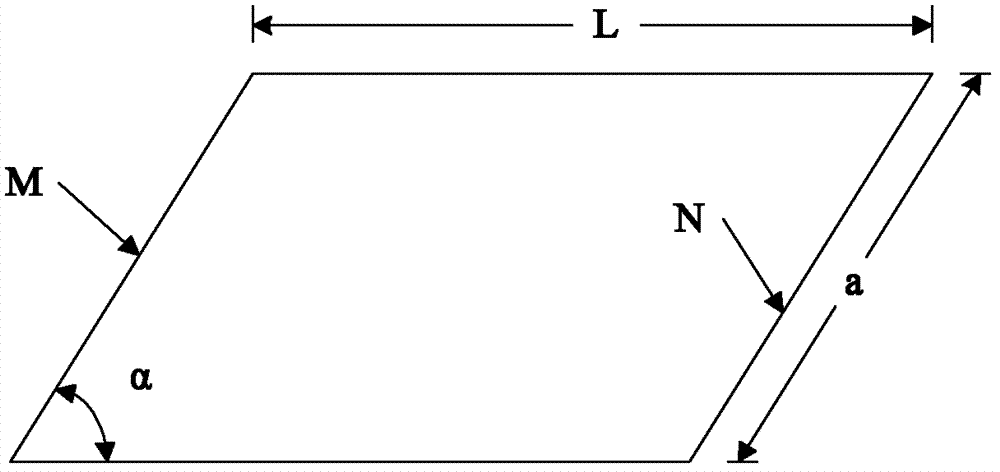

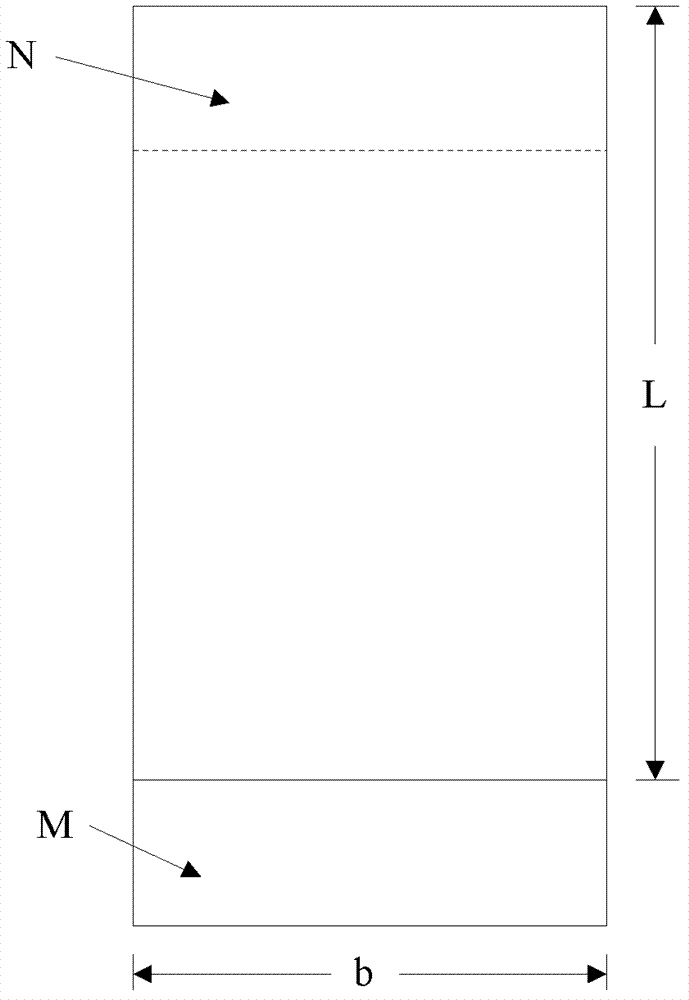

Fresnel prism and method for converting polarization state of terahertz wave

The invention relates to a Fresnel prism and a method for converting a polarization state of a terahertz wave. The Fresnel prism is in a bar-type columnar shape and is made of a material which can not generate a dispersion effect on the terahertz wave. The Fresnel prism comprises four arris and two side surfaces which are opposite and parallel to each other. The two side surfaces are squares with same side lengths. Each arris is perpendicular to one edge of the each side surface. An included angle alpha of the each arris and the each side surface satisfies a formula (1), wherein n is a refractive index of the making material of the Fresnel prism to the terahertz wave. A length of the each arris satisfies that the terahertz wave of incident linear polarization which is perpendicular to one side surface can emit from another side surface after generating even numbers of total reflections in the Fresnel prism. According to the invention, the polarization states of the multi-color linear polarization terahertz waves can be converted into circular polarization simultaneously.

Owner:CAPITAL NORMAL UNIVERSITY

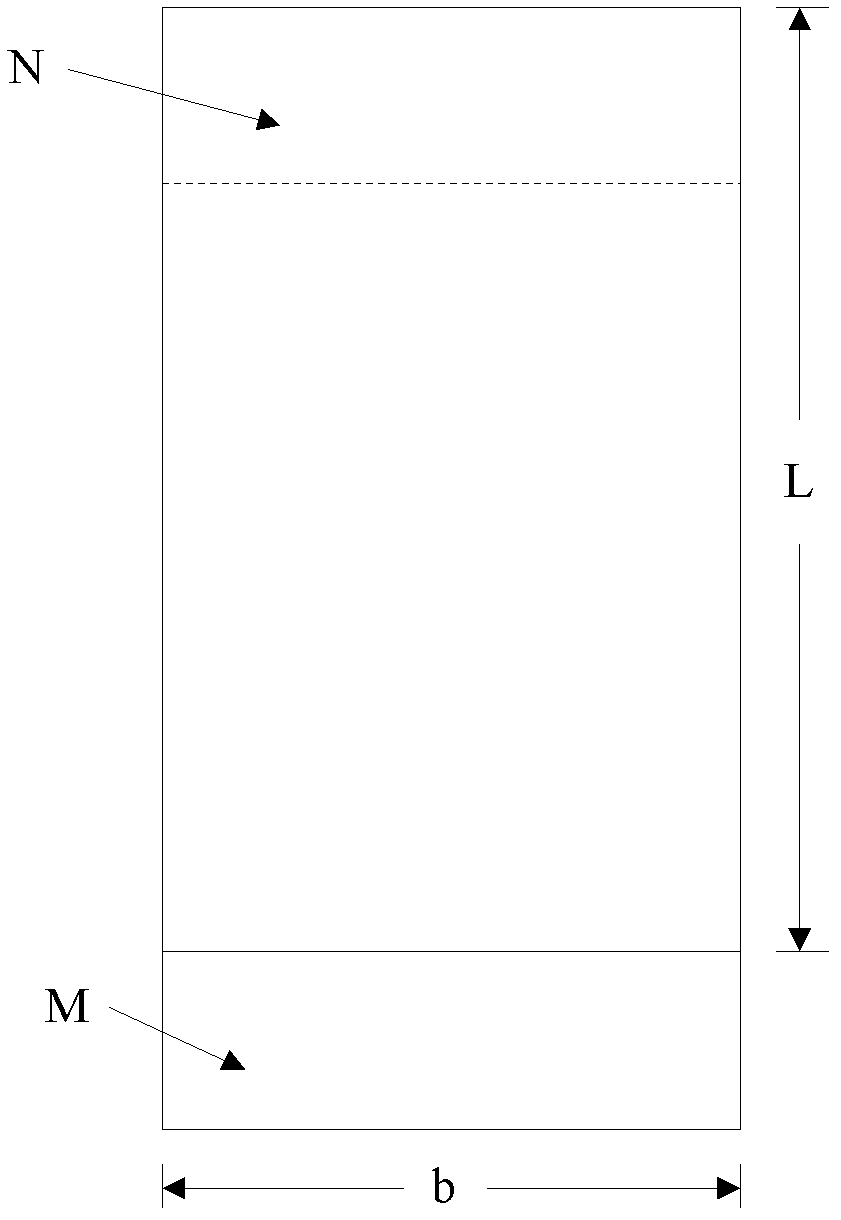

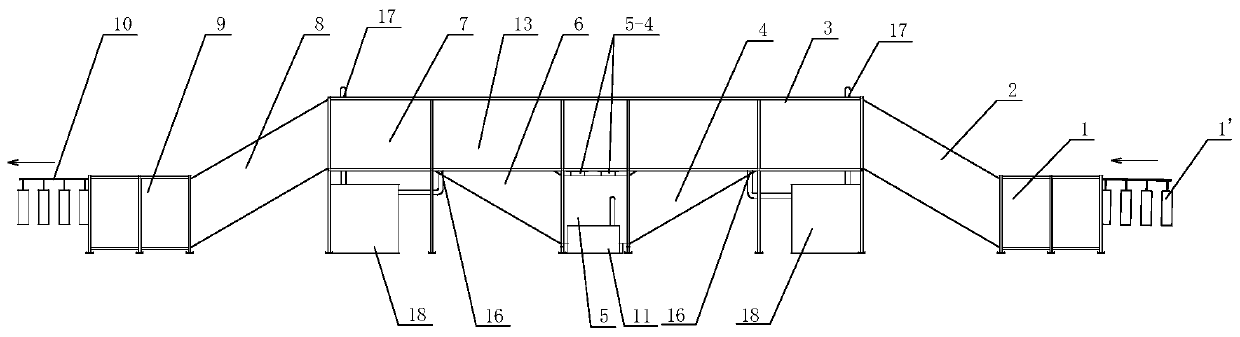

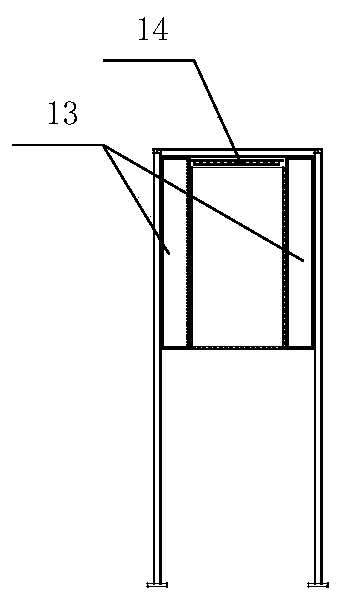

Linear air pressure balance type ultrasonic atomization device

ActiveCN107282358AStructural layout coordinationSmooth connectionLiquid spraying apparatusAtmospheric pressurePressure balance

The invention discloses a linear air pressure balance type ultrasonic atomization device. The linear air pressure balance type ultrasonic atomization device comprises a workpiece conveying channel which is overall linear in the plane projection direction. The workpiece conveying channel is formed by sequentially connecting a low-position workpiece inlet area channel section, an atomization coating front uphill area channel section, an atomization coating front high-position area channel section, an atomization coating front downhill area channel section, a low-position atomization coating area channel section, an atomization coating rear uphill area channel section, an atomization coating rear high-position area channel section, an atomization coating rear downhill area channel section and a low-position workpiece discharging area channel section. High-position air flow circulation channels are connected to the outer portion of the atomization coating front high-position area channel section and the outer portion of the atomization coating rear high-position area channel section. An inlet air curtain machine is arranged at an inlet of the upper end of the atomization coating front downhill area channel section, and an outlet air curtain machine is arranged at an outlet of the upper end of the atomization coating rear uphill area channel section. A waste gas treatment device is connected between a waste gas exhaust connecting opening of the atomization coating front downhill area channel section and a clean air input connecting opening of the atomization coating front high-position area channel section, and a waste gas treatment device is connected between a waste gas exhaust connecting opening of the atomization coating rear uphill area channel section and a clean air input connecting opening of the atomization coating rear high-position area channel section. By means of the device, front and rear equipment connecting on a coating technological line is facilitated.

Owner:李东林 +2

Thread forming fastener

A thread forming fastener for threading into a nut anchor of a pliable material wherein there is produced during the driving of the fastener a combination of forces that encourages the nut anchor material to flow smoothly and to develop a mating thread in the nut anchor that minimizes stress cracking and radial hoop stress as the mating thread is being formed. The fastener comprises a drive head and a shank extending from the head and having a longitudinal axis, the shank including a core and a thread having a selected axial pitch, a selected thread height and a profile which in axial cross-section includes a leading face, a trailing face and a tip. The leading face is composed of a radially inner concave portion having a first radius and which transitions smoothly to a radially outer convex portion having a second radius, the transition occurring at a point on the common tangent to those portions. The trailing face is composed of a radially inner linear portion which transitions at a selected transition location to a radially outer convex portion having a third radius. The profile also includes a convex blending portion having a fourth radius which blends together the radially outer leading and trailing face portions at the tip. The thread profile produces force vectors during assembly with the nut anchor that provide enhanced mating thread strength and improved resistance to nut anchor thread breakdown.

Owner:RES ENG & MFG

Clamping device for ship crane

The invention provides a clamping device for a marine crane and relates to the field of crane accessory manufacturing. The clamping device for a marine crane includes a fixed frame, a motor frame is fixedly installed on the back of the inner wall of the fixed frame, a first motor is fixedly installed on the back of the inner wall of the motor frame, and the output end of the first motor passes through The shaft coupling is fixedly equipped with gears, and the inside of the fixed frame is provided with a tooth plate, and the tooth plate and the gear are meshed with each other. The front of the inner wall of the fixed frame is fixedly installed with a bearing seat, and the bearing seat A connecting shaft is fixedly plugged inside. The clamping device for marine cranes has a simple structure and is easy to use, and can adjust the opening and closing size of the second clamping plate according to the size of the clamped object to achieve the clamping effect of the object, and the anti-slip fixing block can increase the The friction between the second clamping plate, the first clamping plate and the object realizes the effect of efficient clamping.

Owner:无锡市内河装卸机械有限公司

Fresnel prism and method for converting polarization state of terahertz wave

Owner:CAPITAL NORMAL UNIVERSITY

Control device and control method for powertrain, program for implementing the control method, and recording medium containing the program

InactiveUS7901320B2Prevent change of directionReduce shockHybrid vehiclesDigital data processing detailsElectric machineControl theory

A shock caused due to a change in the direction of torque transferred to an output shaft is reduced. There is provided a control device for a powertrain including a drive power source that transfers torque to an output shaft connected to a wheel of a vehicle, and a rotary electric machine that transfers torque to the output shaft via a transmission. When electric power generation performed using the rotary electric machine is restricted, if torque that decelerates the vehicle is transferred from the drive power source to the output shaft, a control is executed so that torque that does not decelerate the vehicle is transferred from the drive power source to the output shaft, and a shift control over the transmission is executed.

Owner:TOYOTA JIDOSHA KK +1

Rubber hose laying device

ActiveCN110886903BReduced shaking tendencyLimit shakingPipe laying and repairMarine engineeringGear wheel

Owner:WUHAN UNIV OF TECH

Method and apparatus for recovering inferior cigarettes and tobacco by gas separation

InactiveCN1301073COrderly rowsAchieving lateral feedingTobacco preparationCigarette manufactureAir separationProduct gas

Owner:魏积斌 +2

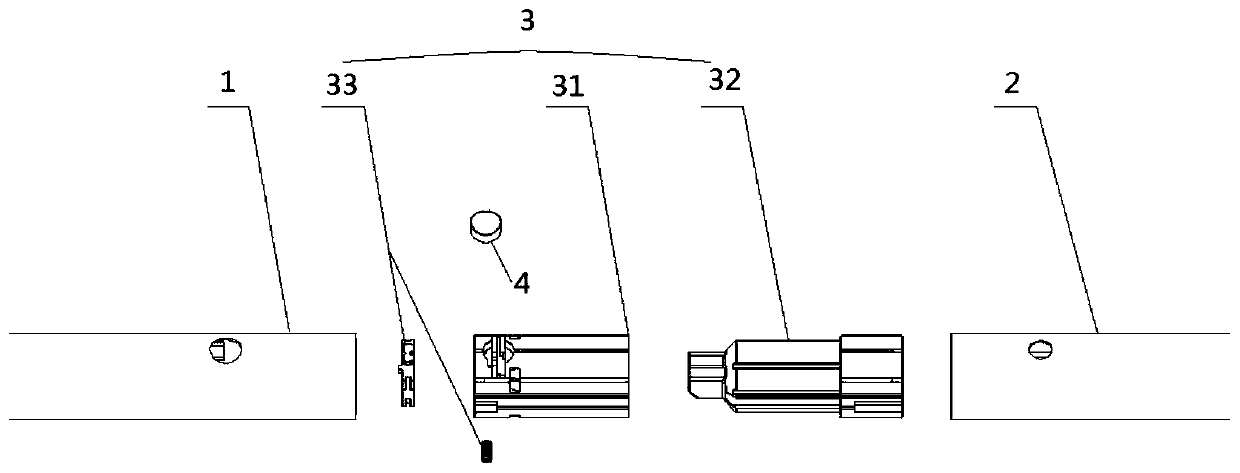

Butt joint structure and fan with butt joint structure

PendingCN110953229AEasy and quick installationGuaranteed stabilityRod connectionsButt jointEngineering

The invention provides a butt joint structure and a fan with the butt joint structure. The butt joint structure comprises a first connecting piece, a second connecting piece, a butt joint component, and a button; a first groove and a second groove are respectively formed in the butt joint surface of the first connecting piece and the butt joint surface of the second connecting piece; the butt joint component is arranged on the first groove and the second groove and comprises a female joint arranged in the first groove, a male joint arranged on the second groove and provided with a clamping head which protrudes out of the second groove, and a locking and buckling component, wherein the circumferential surface of the female joint is provided with a passing hole, at the passing hole position,the locking and buckling component can be movably arranged in the female joint in the direction perpendicular to the butt joint direction, and the clamping head is clamped on the locking and bucklingcomponent after the butt joint is in place; and the button is arranged on the locking and buckling component and drives the locking and buckling component to move under the action of an external force so as to make the clamping head separate from the locking and buckling component. The butt joint structure is simple and convenient to assemble and disassemble.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

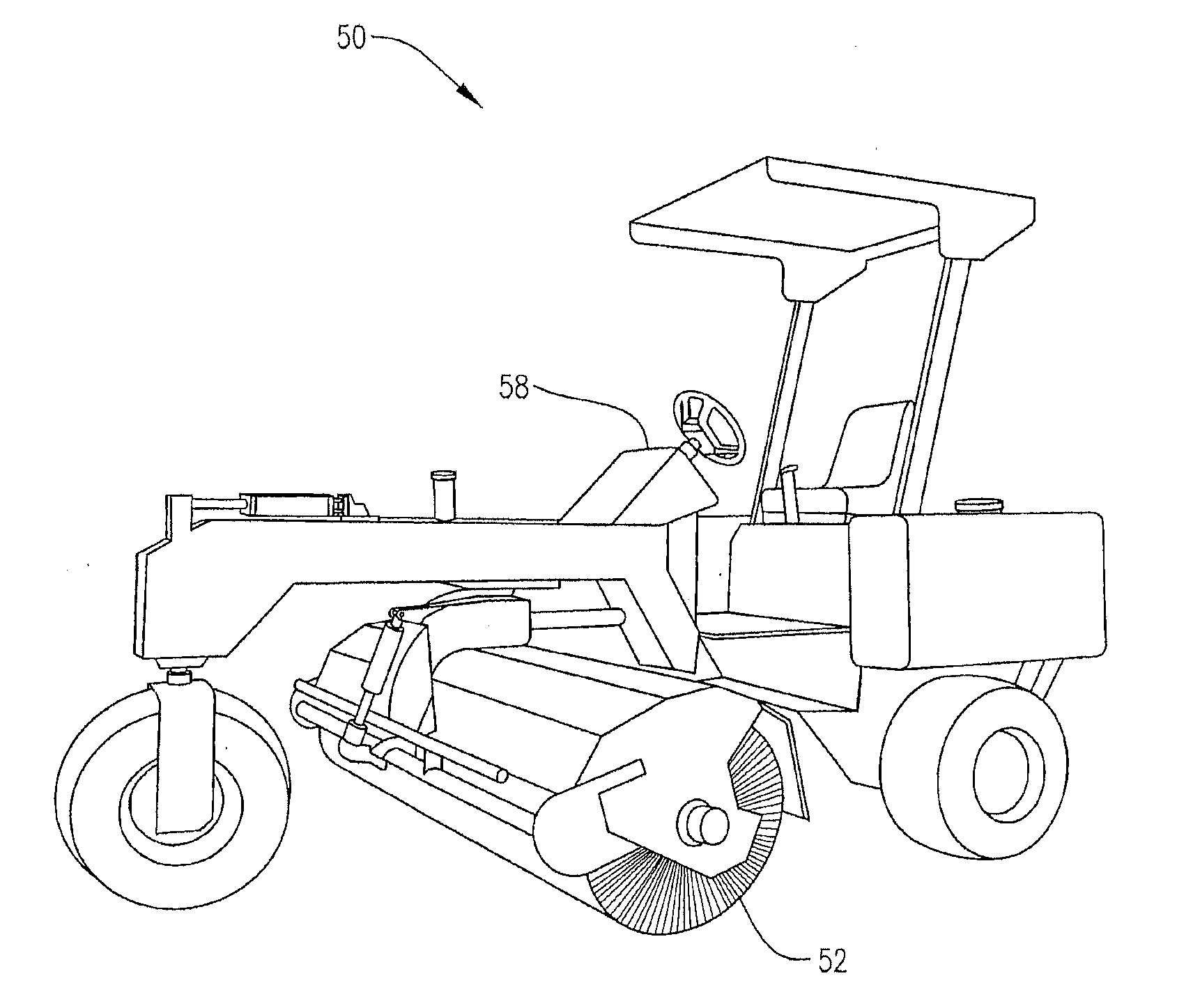

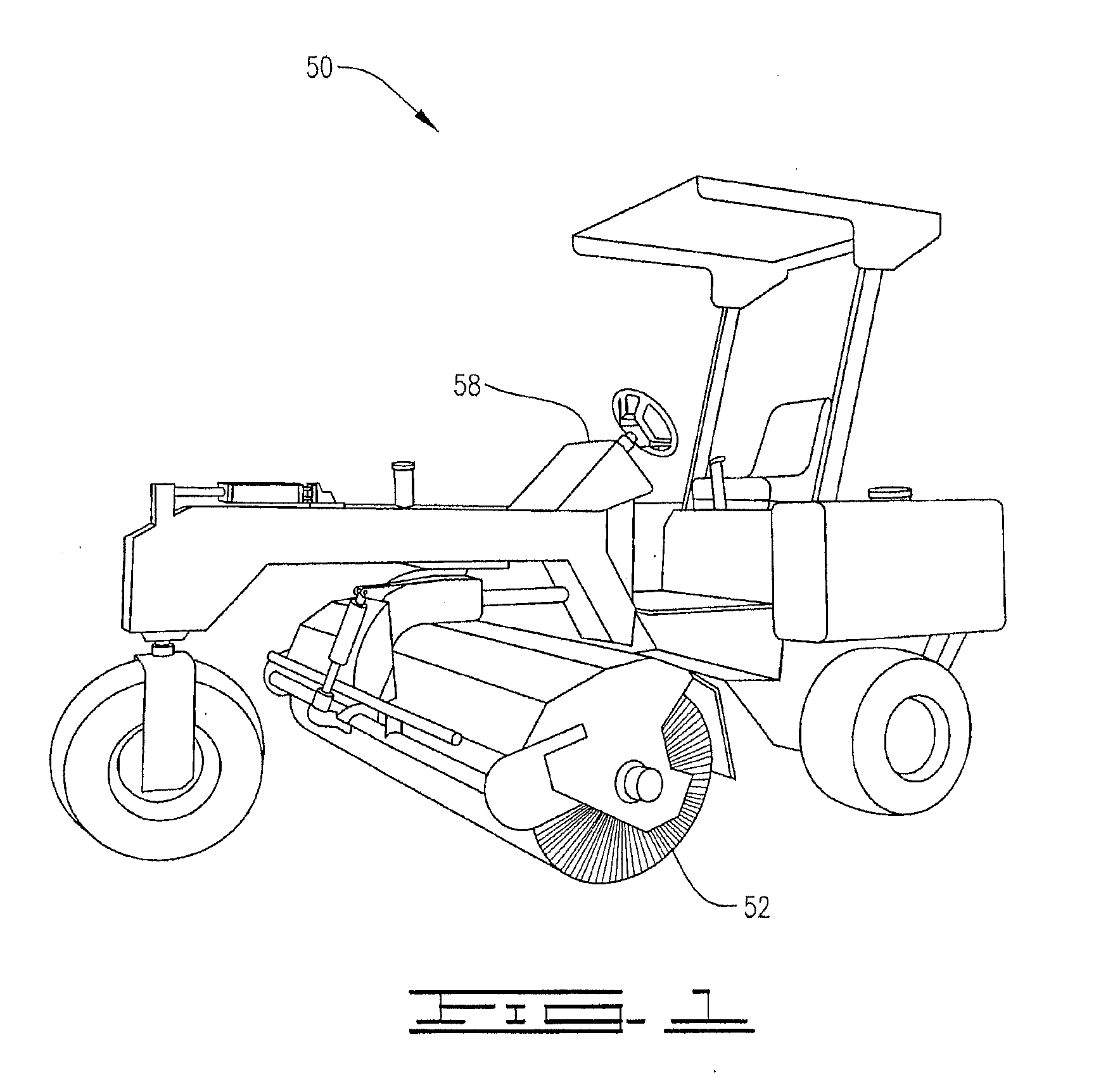

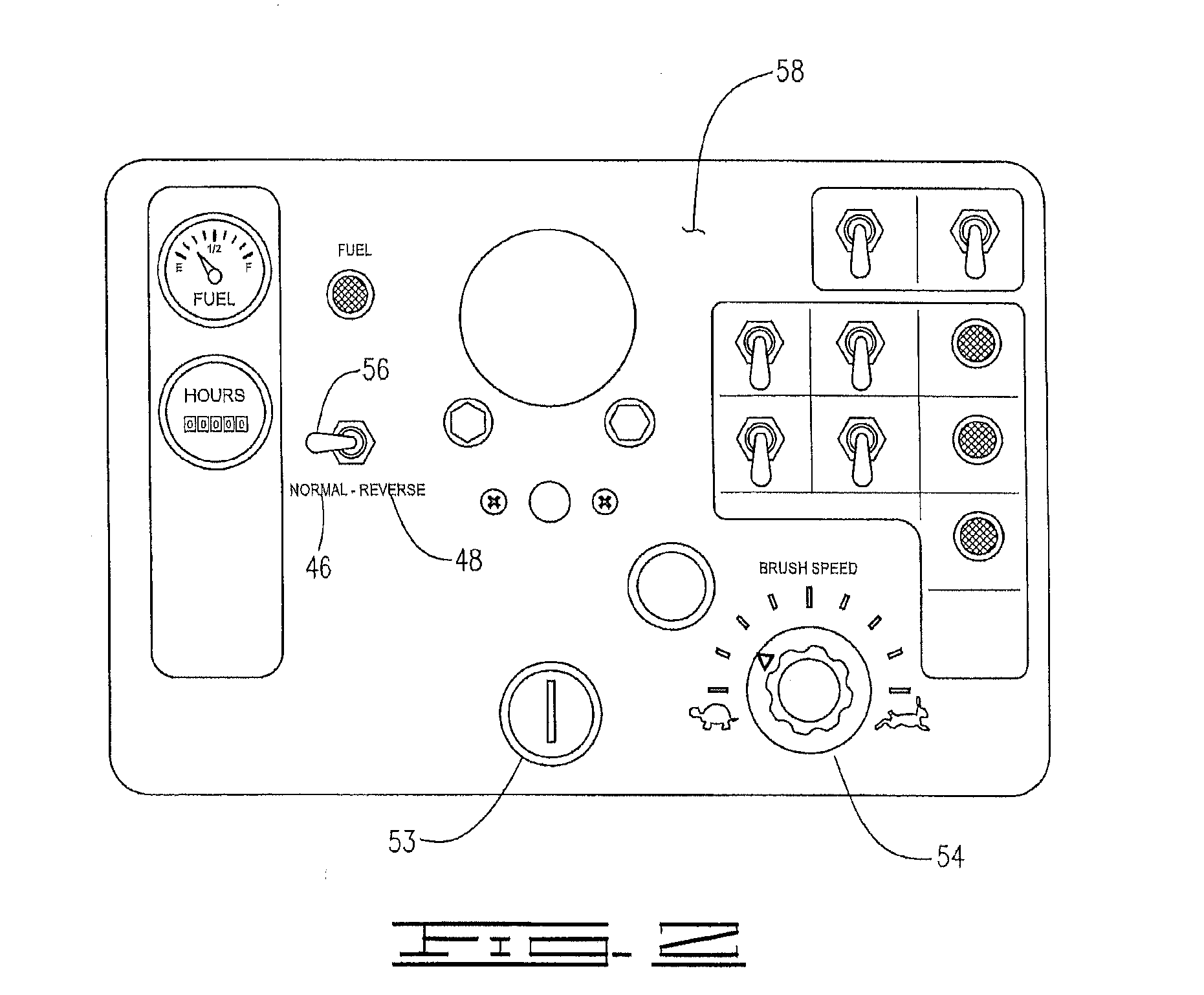

Hydraulic control system for use with a turf sweeper

InactiveUS20160143226A1Prevent change of directionHops/wine cultivationSuction cleanersControl systemHydraulic control

A turf sweeper with a rotatable brush including an adaptable hydraulic control system is disclosed. The turf sweeper includes a controller adapted to modify the hydraulic system to affect the rotational speed and direction of the rotatable brush. The controller and hydraulic control system are adapted such that the rotatable brush will not rotate if the turf sweeper is turned on and the speed adjuster for the rotatable brush is not set to the zero speed setting.

Owner:BROCE MFG CO

Burst-proof safety tyre of vehicle

InactiveUS8684055B2Prevent change of directionSize of supportWithout separate inflatable insertsRimsEngineeringVALVE PORT

The present invention relates to an explosion-proof security tire for vehicles. The tire includes an outer tire, a split rim, a L-shaped sealing ring, a combined support loop and a valve core. The combined support loop includes a plurality layers of support rings they are sleeved by layer on layer and fixed with the rim. The size of the tire can increased by the combined support loop so as to furthest shorten the distance between the inner wall of the outer tire and the outer wall of the combined support loop at a normal pressure of tire. At the moment that the tire is burst, the combined support loop can support the outer tire quickly and effectively, and control the change of acting radius of the tire in a minimum range so as to ensure the basic performance of the tire and to prevent accidents caused by sudden control loss of running direction and avoid potential security risks. Moreover, the split rim is benefit for mounting the combined support loop by layering, and is easy to be assembled and disassembled so that the tire can be maintained and replaced by normal tools.

Owner:WU XIAOYIN +1

A linear air pressure balanced ultrasonic atomization device

ActiveCN107282358BStructural layout coordinationSmooth connectionLiquid spraying apparatusExhaust fumesPressure balance

The invention discloses a linear air pressure balance type ultrasonic atomization device. The linear air pressure balance type ultrasonic atomization device comprises a workpiece conveying channel which is overall linear in the plane projection direction. The workpiece conveying channel is formed by sequentially connecting a low-position workpiece inlet area channel section, an atomization coating front uphill area channel section, an atomization coating front high-position area channel section, an atomization coating front downhill area channel section, a low-position atomization coating area channel section, an atomization coating rear uphill area channel section, an atomization coating rear high-position area channel section, an atomization coating rear downhill area channel section and a low-position workpiece discharging area channel section. High-position air flow circulation channels are connected to the outer portion of the atomization coating front high-position area channel section and the outer portion of the atomization coating rear high-position area channel section. An inlet air curtain machine is arranged at an inlet of the upper end of the atomization coating front downhill area channel section, and an outlet air curtain machine is arranged at an outlet of the upper end of the atomization coating rear uphill area channel section. A waste gas treatment device is connected between a waste gas exhaust connecting opening of the atomization coating front downhill area channel section and a clean air input connecting opening of the atomization coating front high-position area channel section, and a waste gas treatment device is connected between a waste gas exhaust connecting opening of the atomization coating rear uphill area channel section and a clean air input connecting opening of the atomization coating rear high-position area channel section. By means of the device, front and rear equipment connecting on a coating technological line is facilitated.

Owner:李东林 +2

An automobile air outlet blade transmission mechanism

ActiveCN106739965BPrevent change of directionTransmission is not easyAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

The invention discloses an automobile air outlet blade transmission mechanism, which comprises an automobile air outlet assembly casing, a partition plate is arranged inside the automobile air outlet assembly casing, and a plurality of The first blade and the second blade, the first blade and the second blade are perpendicular to each other, and the adjacent first blades are parallel to each other, one end of the first blade is provided with a first rotating shaft, and the other end of the first blade is provided with a second A shaft, a gear is clamped on the second shaft, a guide block is sleeved on the outside of the first blade, a through hole is opened inside the guide block, the side wall of the through hole is slidingly connected with the first blade, the first shaft and The second rotating shaft is movably connected with the housing of the automobile air outlet assembly and the partition plate respectively, and the gears on the adjacent first blades mesh with each other, and the gears are located on a straight line. The invention has the advantages of simple structure, good transmission effect and locking function, which prevents the blades from being changed in direction by the vibration of the vehicle or the action of gravity.

Owner:CHUZHOU SHUNYU MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com