Orientation arrangement apparatus for capsule and pill

A technology of directional arrangement and capsules, which is applied in the direction of making medicines into special physical or taking forms, and can solve the problems of high hygiene standards, low efficiency, and affecting mechanized canned medicine powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

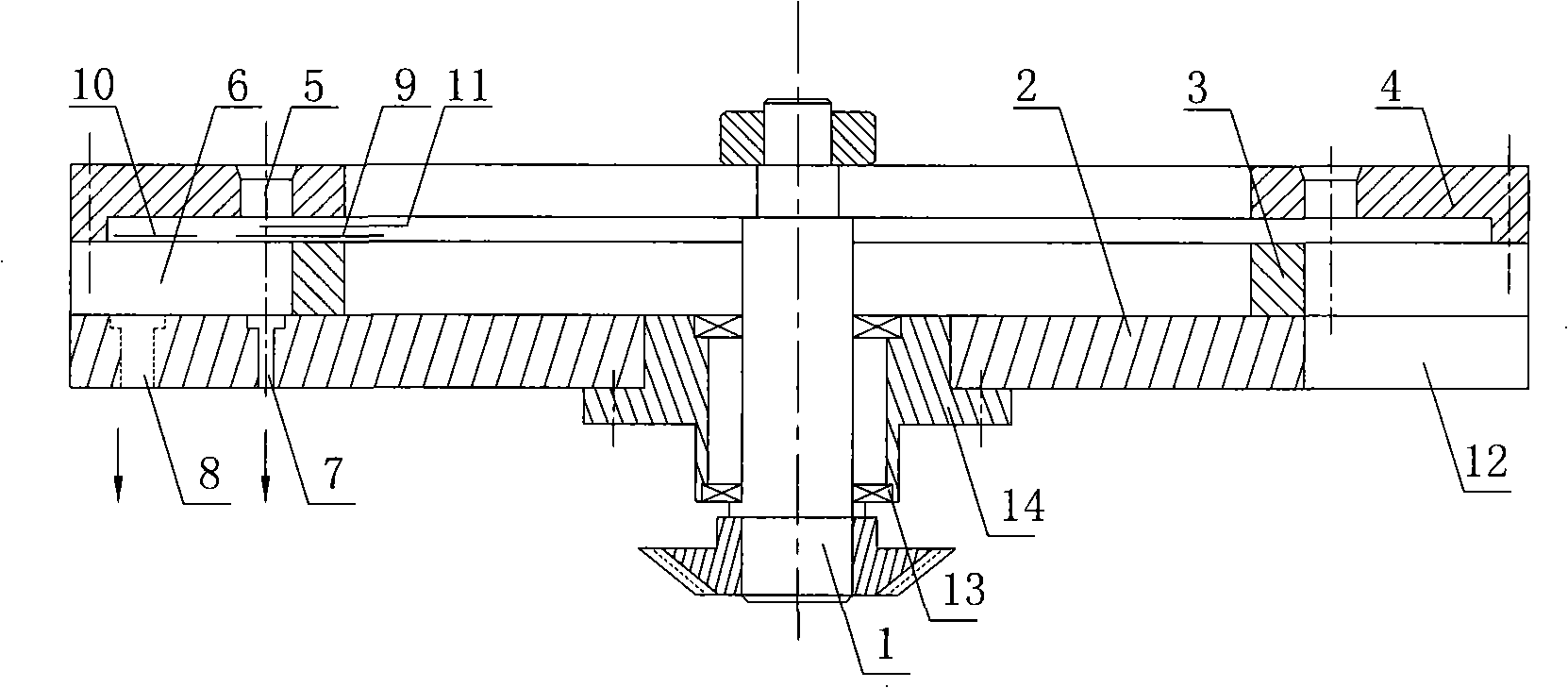

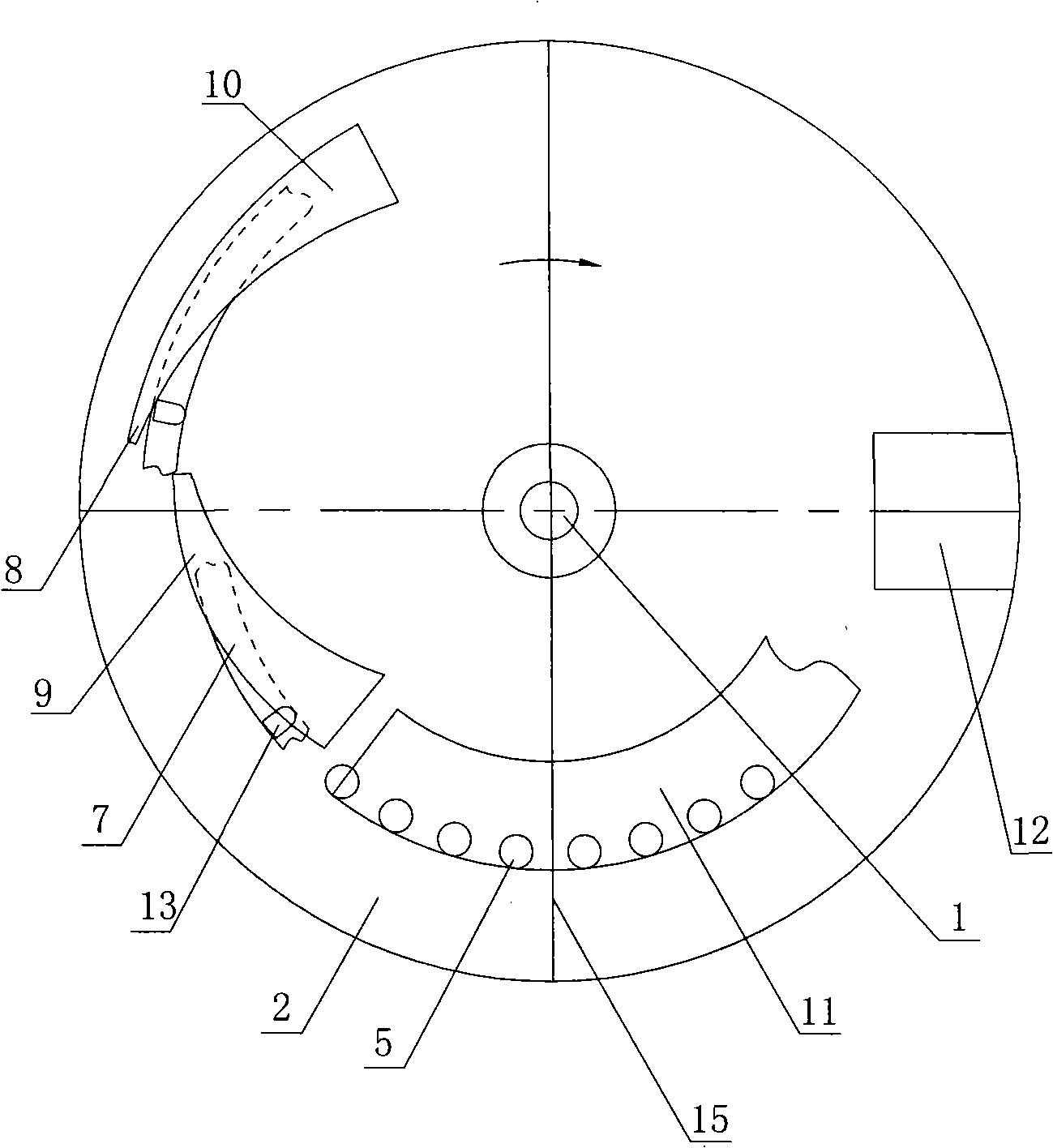

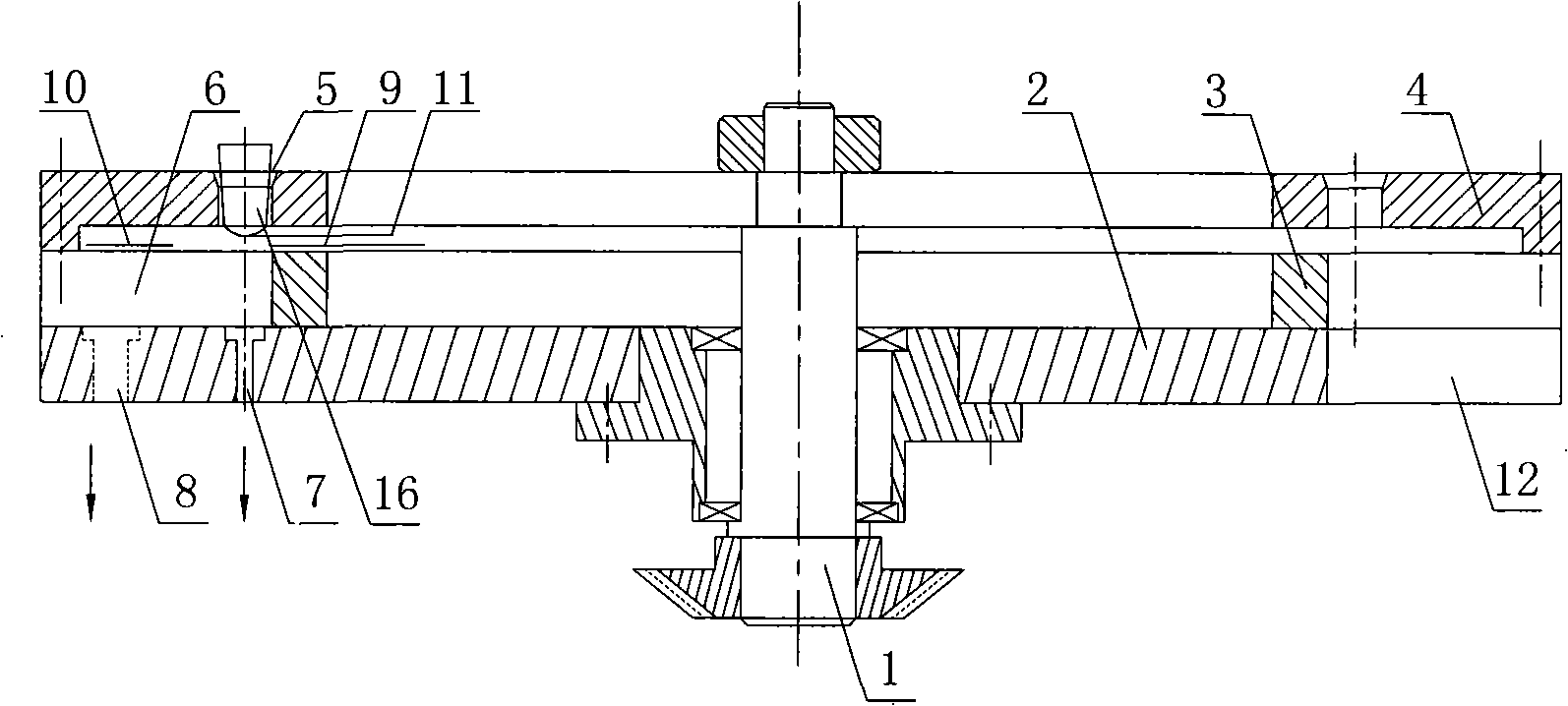

[0017] Such as figure 1 , 2 As shown, the capsule orientation arrangement device includes a blanking plate 4 with a plurality of blanking holes 5, the blanking plate 4 is circular, and the blanking holes 5 are arranged in a circular array with the center of the blanking plate 4 as the center. The central axis 1 is connected to the center of the blanking plate 4. A cross-cutting plate 3 whose outer edge is located inside the blanking hole 5 is arranged coaxially under the blanking plate 4. Between the blanking plate 4 and the cross-cutting plate 3, there is a The forward baffle 9, the reverse baffle 10, and the bridging splint 11 higher than the two, the bridging plywood 11 and the forward baffle 9 are staggered and located below the blanking hole 5, and the reverse baffle 10 is located in the blanking Outer side of the hole 5, a chassis 2 connected to the central shaft 1 through a bearing 13 is provided below the cross-cut plate 3. The bearing 13 is externally connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com