Hot-pressing equipment for producing long-fiber high-strength fiber plate

A high-strength fiber, hot-pressing equipment technology, used in applications, household components, household appliances, etc., can solve the problems of unidirectional arrangement of coconut fibers, weak fiber interaction, affecting the mechanical properties of coconut fiber boards, etc. performance, improve accuracy, avoid the effect of changing the direction of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

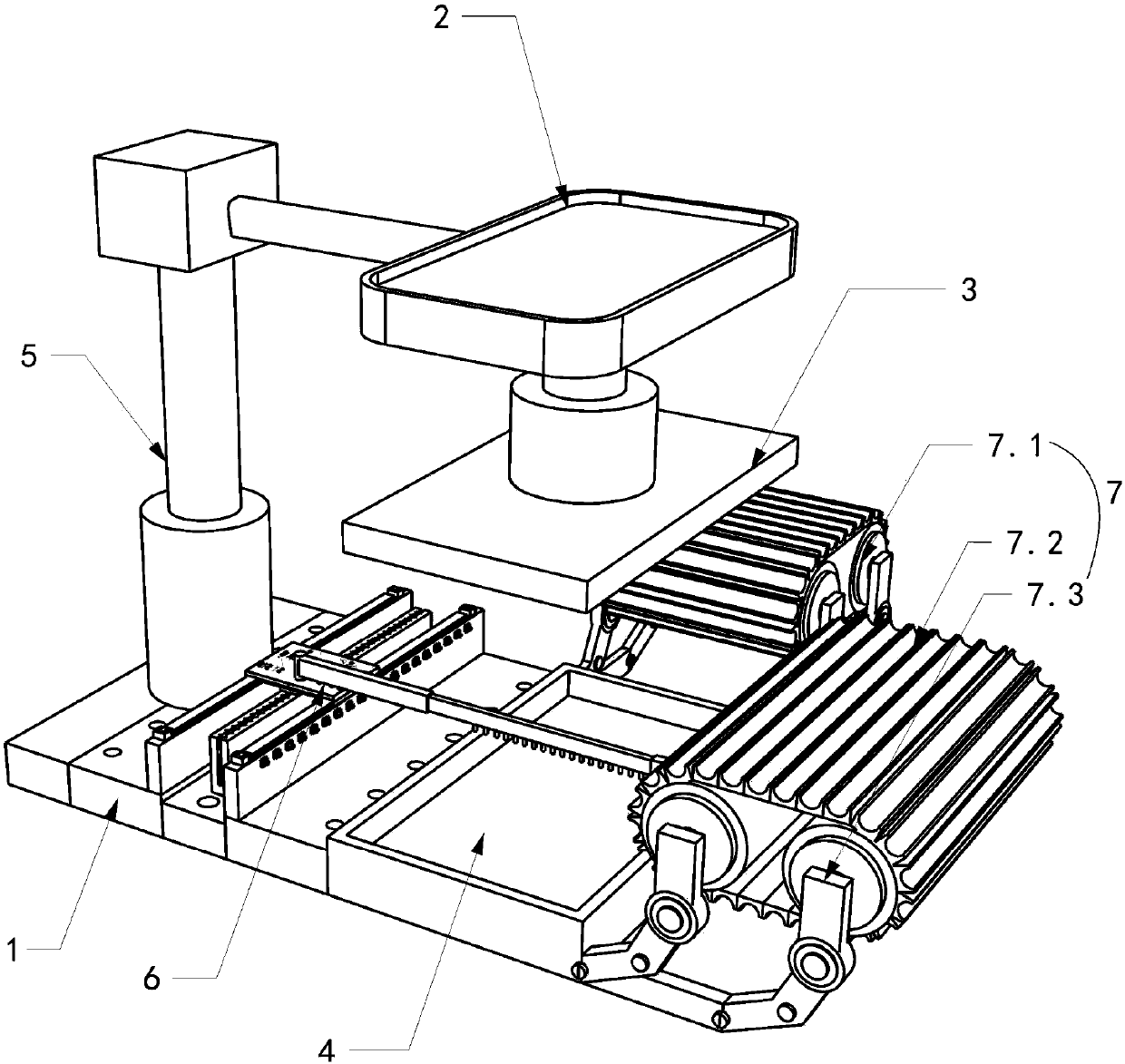

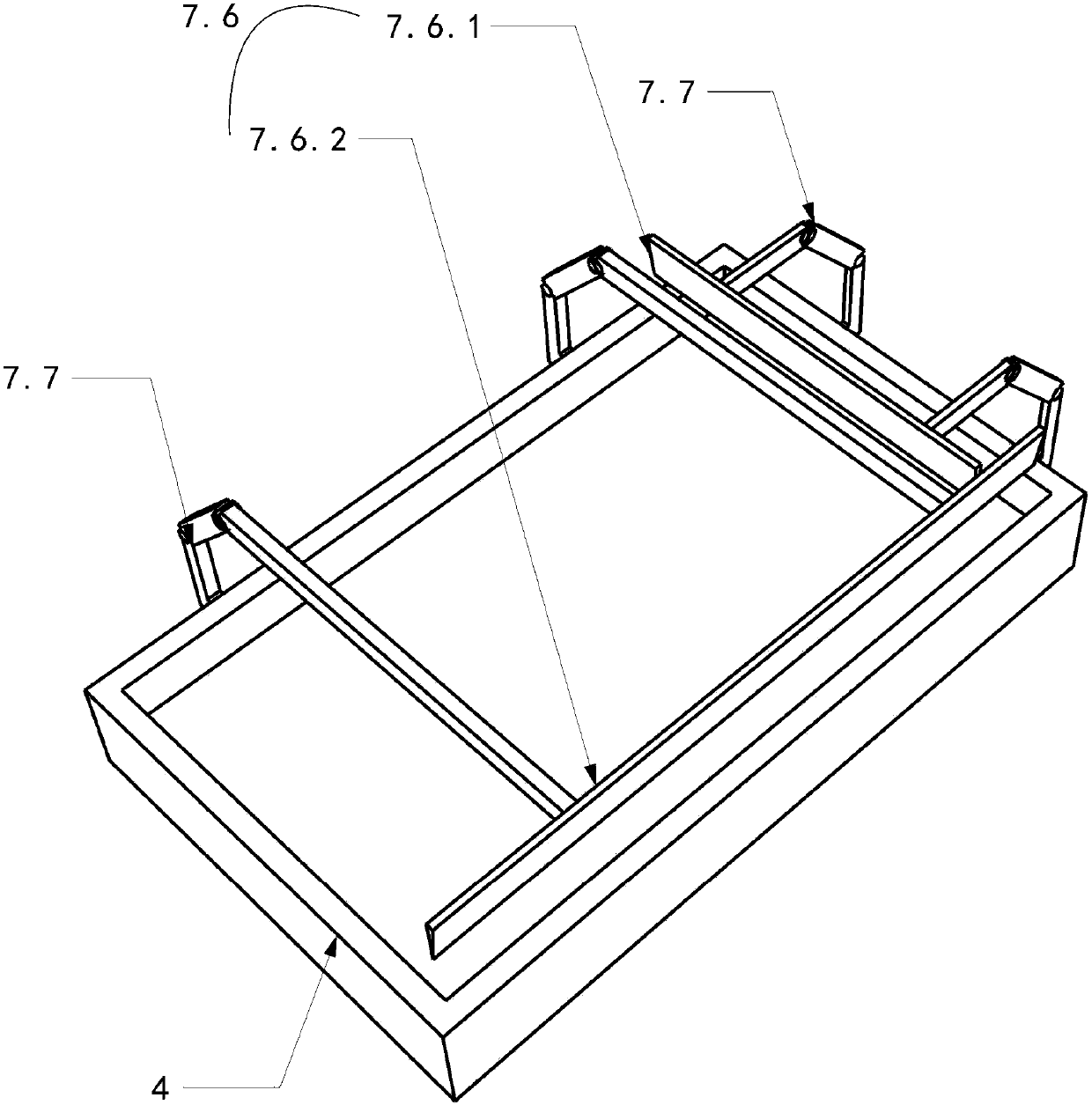

[0028] Embodiment 1, a hot-pressing device for producing long-fiber high-strength fiberboard, including a machine base 1, a fuselage 2, a mechanical telescopic press plate 3, and a pressure groove 4 matched with the mechanical telescopic press plate 3, and the fuselage 2 is fixed Above the base 1, a device for controlling the temperature and rise and fall of the mechanical telescopic pressing plate 3 is installed inside the fuselage 2. The mechanical telescopic pressing plate 3 is connected to the fuselage 2 through a hydraulic rod 5. The lower surface of the mechanical telescopic pressing plate 3 is a heat-conducting metal plate. The pressure groove 4 is opened on the machine base 1, and the pressure groove 4 is located directly below the mechanical telescopic pressing plate 3, and the surrounding edges of the pressure groove 4 are higher than the machine base 1, so as to prevent material leakage. The pressure groove is rectangular, and the groove depth of the pressure groove ...

Embodiment 2

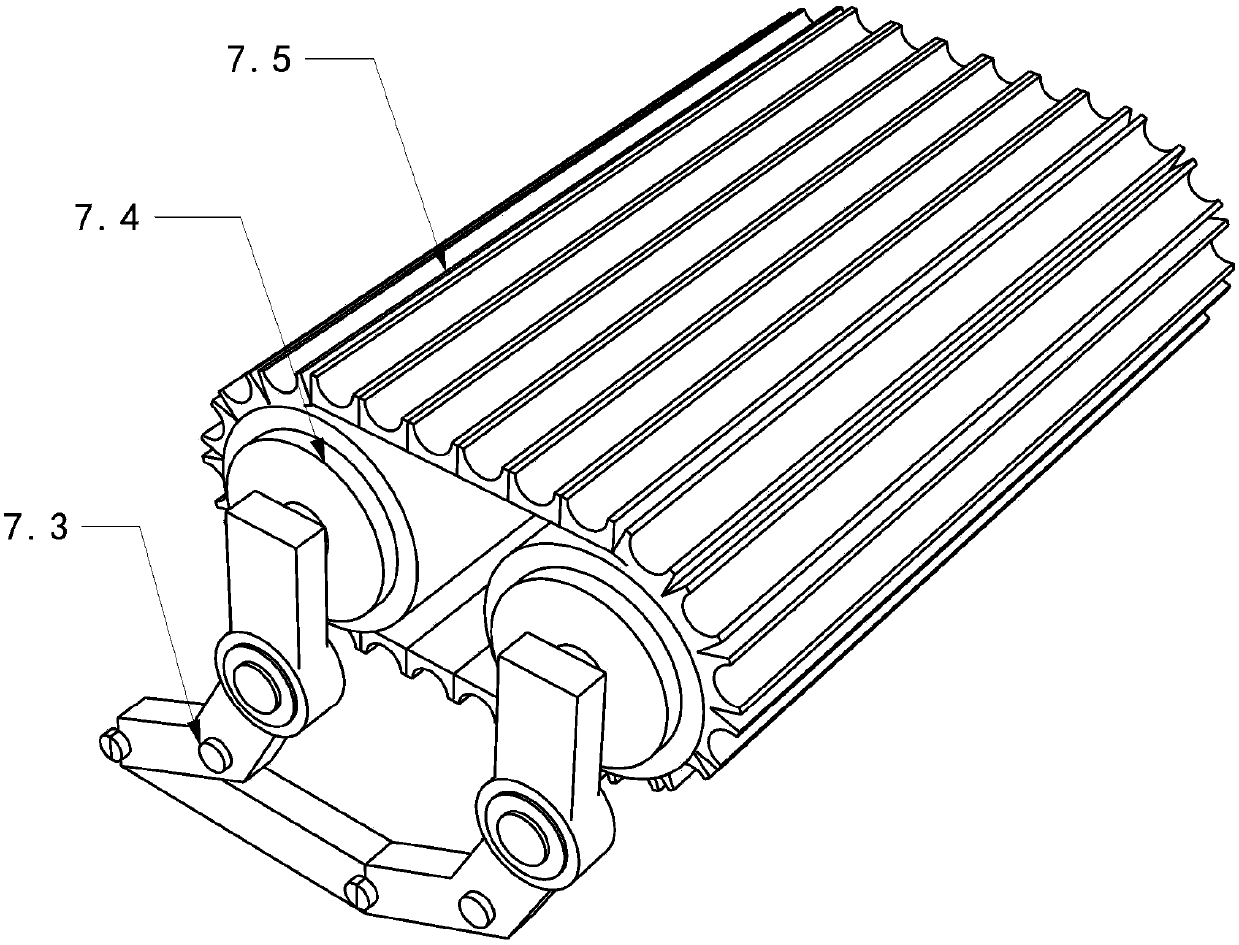

[0032]Embodiment 2, this embodiment has made the following optimizations on the basis of Embodiment 1: the X-axis conveyor 7.1 of this embodiment includes a support bar 7.3, a roller 7.4, and a U-shaped tape reel 7.5, and the support bar The end of 7.3 is fixed to the side of the pressure groove 4, the roller 7.4 is connected to the support bar 7.3 through the rotating shaft, and the U-shaped tape reel 7.5 is sleeved on the outer ring of the roller 7.4.

Embodiment 3

[0033] Embodiment 3, this embodiment has made the following optimizations on the basis of Embodiment 1: the Y-axis conveyor 7.2 of this embodiment includes a support bar 7.3, a roller 7.4, and a U-shaped tape reel 7.5, and the support bar The end of 7.3 is fixed to the side of the pressure groove 4, the roller 7.4 is connected to the support bar 7.3 through the rotating shaft, and the U-shaped tape reel 7.5 is sleeved on the outer ring of the roller 7.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com