Linear air pressure balance type ultrasonic atomization device

A technology of air pressure balance and ultrasonic atomization, which can be used in injection devices, liquid injection devices, etc., which can solve problems such as unfavorable utilization of plant space, increased drive motor load, inconvenient connection between front and rear devices, etc., to facilitate equipment installation and improve stability. , to avoid the effect of changing direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

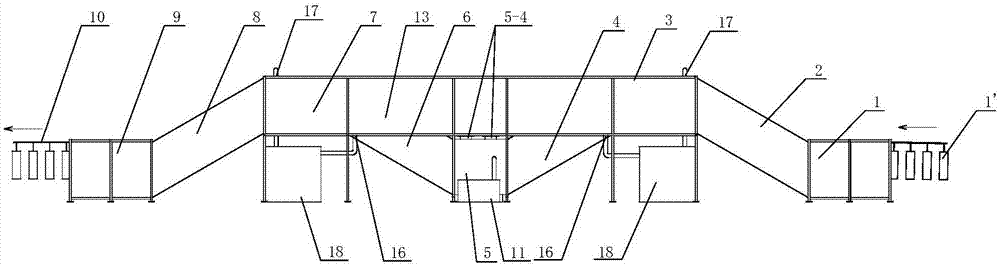

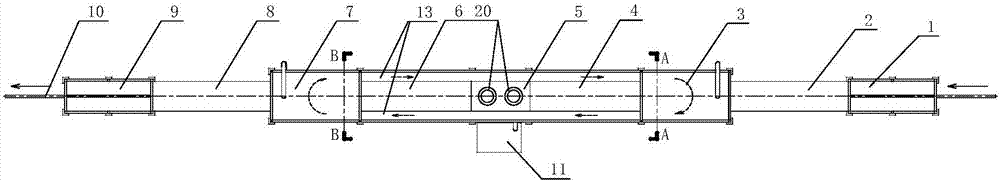

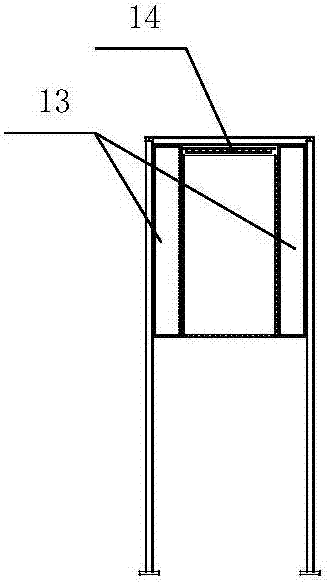

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0033] see Figure 1-7 , a linear air pressure balanced ultrasonic atomization device, including a workpiece conveying channel, the workpiece conveying channel is composed of a channel section 1 in the low-level entry area, a channel section 2 in the climbing area before fog coating, a channel section 3 in the high-level area before fog coating, and a fog coating. Channel section 4 in the downhill area before coating, channel section 5 in the low fog coating area, channel section 6 in the climbing area after fog coating, channel section 7 in the high level area after fog coating, channel section 8 in the downhill area after fog coating, and the low delivery area The channel segments 9 are successively connected and formed. Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com